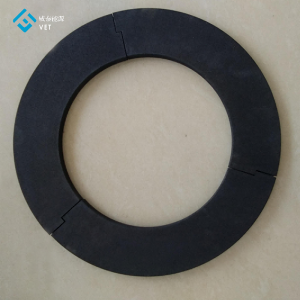

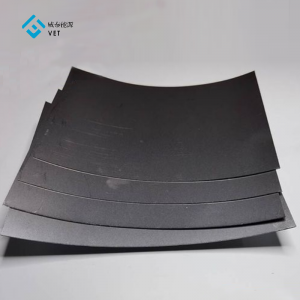

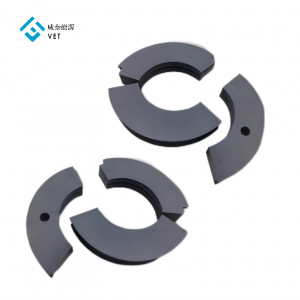

VET Energy PECVD loading tray is a precision carrier designed for PECVD (plasma enhanced chemical vapor deposition) process. This high-quality deposition graphite tray is made of high-purity, high-density graphite material. It has excellent high temperature resistance, corrosion resistance, dimensional stability and other characteristics. It can provide a stable carrier platform for PECVD process and ensure the uniformity and flatness of film deposition.

VET Energy PECVD loading trays are widely used in semiconductor, photovoltaic, LED and other fields. For example:

▪ Semiconductor: PECVD process for semiconductor materials such as silicon wafers and epitaxial wafers.

▪ Photovoltaic: PECVD process for solar cell thin films.

▪ LED: PECVD process for LED chips.

Product Advantages

▪ Improve film quality: Ensure uniform film deposition and improve film quality.

▪ Extend equipment life: Excellent corrosion resistance, extend the service life of PECVD equipment.

▪ Reduce production costs: High-quality graphite trays can reduce scrap rate and reduce production costs.

Graphite material from SGL:

|

Typical parameter: R6510 |

|||

| Index | Test standard | Value | Unit |

| Average grain size | ISO 13320 | 10 | μm |

| Bulk density | DIN IEC 60413/204 | 1.83 | g/cm3 |

| Open porosity | DIN66133 | 10 | % |

| Medium pore size | DIN66133 | 1.8 | μm |

| Permeability | DIN 51935 | 0.06 | cm²/s |

| Rockwell hardness HR5/100 | DIN IEC60413/303 | 90 | HR |

| Specific electrical resistivity | DIN IEC 60413/402 | 13 | μΩm |

| Flexural strength | DIN IEC 60413/501 | 60 | MPa |

| Compressive strength | DIN 51910 | 130 | MPa |

| Young's modulus | DIN 51915 | 11.5×10³ | MPa |

| Thermal expansion(20-200℃) | DIN 51909 | 4.2X10-6 | K-1 |

| Thermal conductivity (20℃) | DIN 51908 | 105 | Wm-1K-1 |

It is specifically designed for high-efficiency solar cell manufacturing, supporting G12 large-size wafer processing. Optimized carrier design significantly increases throughput, enabling higher yield rates and lower production costs.

| Item | Type | Number wafer carrier |

| PEVCD Grephite boat - The 156 series | 156-13 grephite boat | 144 |

| 156-19 grephite boat | 216 | |

| 156-21 grephite boat | 240 | |

| 156-23 graphite boat | 308 | |

| PEVCD Grephite boat - The 125 series | 125-15 grephite boat | 196 |

| 125-19 grephite boat | 252 | |

| 125-21 grphite boat | 280 |