OEM/ODM Manufacturer Silicon Carbide Coating Processing - Personlized Products China Silicon Carbon Crucible for Ferrous and Non-Ferrous Alloys – VET Energy Detail:

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for Personlized Products China Silicon Carbon Crucible for Ferrous and Non-Ferrous Alloys, To acquire a consistent, profitable, and constant advancement by getting a competitive advantage, and by continuously increasing the price added to our shareholders and our employee.

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for China Silica Graphite Crucible, Graphite Foundry Crucible, Our company is an international supplier on this kind of merchandise. We supply an amazing selection of high-quality merchandise. Our goal is to delight you with our distinctive collection of mindful items while providing value and excellent service. Our mission is simple: To supply the best items and service to our customers at the lowest prices possible.

Carbon / carbon composites (hereinafter referred to as “C / C or CFC”) is a kind of composite material which is based on carbon and reinforced by carbon fiber and its products (carbon fiber preform). It has both the inertia of carbon and the high strength of carbon fiber. It has good mechanical properties, heat resistance, corrosion resistance, friction damping and thermal and electrical conductivity characteristics

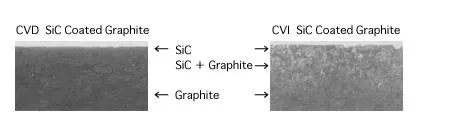

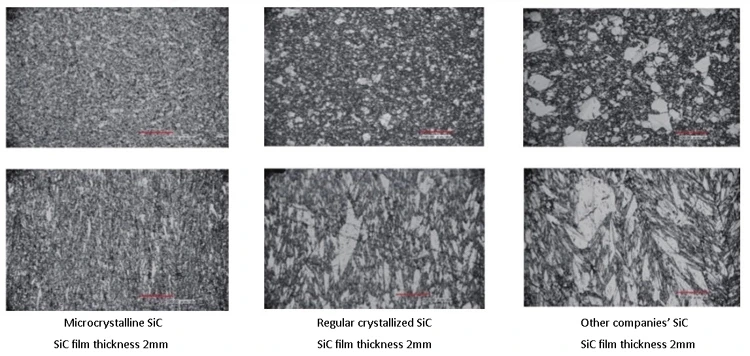

CVD-SiC coating has the characteristics of uniform structure, compact material, high temperature resistance, oxidation resistance, high purity, acid&alkali resistance and organic reagent, with stable physical and chemical properties.

Compared with high-purity graphite materials, graphite begins to oxidize at 400C, which will cause a loss of powder due to oxidation, resulting in environmental pollution to peripheral devices and vacuum chambers, and increase impurities of high-purity environment.

However, SiC coating can maintain physical and chemical stability at 1600 degrees, It is widely used in modern industry, especially in semiconductor industry.

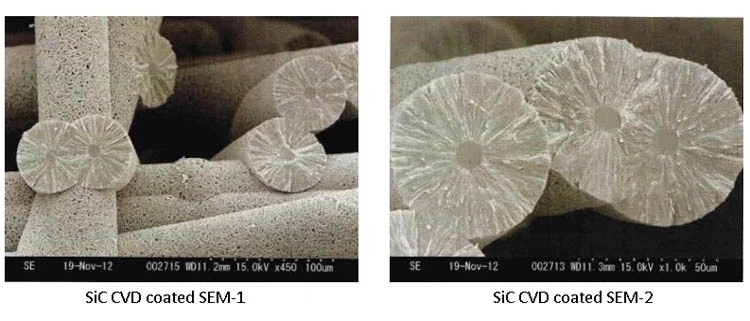

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity: made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coatings:

|

SiC-CVD |

||

| Density |

(g/cc)

|

3.21 |

| Flexural strength |

(Mpa)

|

470 |

| Thermal expansion |

(10-6/K) |

4

|

| Thermal conductivity |

(W/mK) |

300

|

Product detail pictures:

Related Product Guide:

How to Weather Model Kits: Everything You Need to Create Realistic Weathering Effects on Plastic Model Kits | Fire Water Cannon

Water Cannon Market Trends and Competitive Landscape Outlook to 2023 – EST, MEGA, Prime-Pump | 2” Or 3” Or 4”Manual Butterfly Valve

OEM/ODM Manufacturer Silicon Carbide Coating Processing - Personlized Products China Silicon Carbon Crucible for Ferrous and Non-Ferrous Alloys – VET Energy, The product will supply to all over the world, such as: , , ,

-

China New ProductGraphite Crucible For Melting ...

-

Manufacturer for Tube - Bottom price For Boat ...

-

Big Discount Graphite Seal Ring - 700mm/600mm ...

-

Super Lowest Price Carbon Fiber Bolt - Graphit...

-

Factory Price For Thermal Expansion Valve - Gr...

-

Good Quality Graphite Electrode - 2019 wholesa...