OEM/ODM Manufacturer Silicon Carbide Coating Processing - OEM Customized Sale Thermal Conductivity Graphite Sheet – VET Energy Detail:

We pursue the administration tenet of “Quality is top-quality, Company is supreme, Track record is first”, and will sincerely create and share success with all purchasers for OEM Customized Sale Thermal Conductivity Graphite Sheet, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

We pursue the administration tenet of “Quality is top-quality, Company is supreme, Track record is first”, and will sincerely create and share success with all purchasers for Graphite Sheet, Hith Thermal Conductivity Graphite Sheet, Low Thermal Tesistance Graphite Sheet, We are going to supply much better merchandise with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information make sure you feel free to contact us. We’ve been looking forward to receiving your enquiries soon.

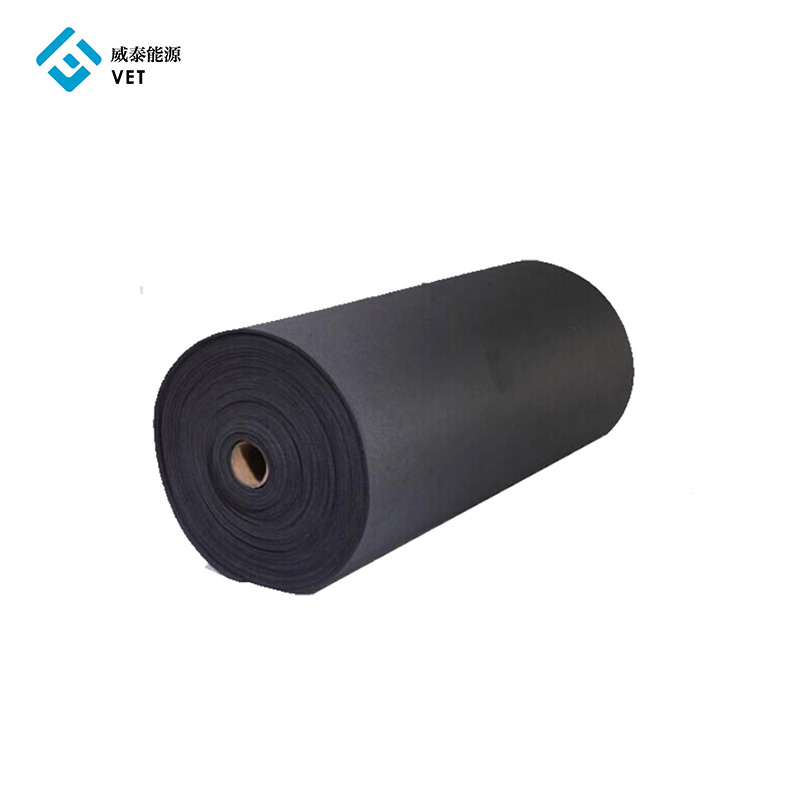

Soft Carbon Graphite Felt PAN-based, Carbon Felt Insulation Roll for Inert gas furnaces

Data:

-Density: 0.12g/cm3

-Tensile strength: 0.12-0.3mpa

-Thermal conductivity: W/M.K

0.09-0.13 (25C) /0.2-0.27 (1000C)

-Specific resistance: 0.18-0.22 ohm.cm

-Carbon content: 97%

-Ash content: 0.5%

-Moisture absorption: 2%

-Processing temperature: 1000-1450C

-Operating temperature:

In the air 400C

Vacuum 1500C

In the Inert atmosphere 1800C

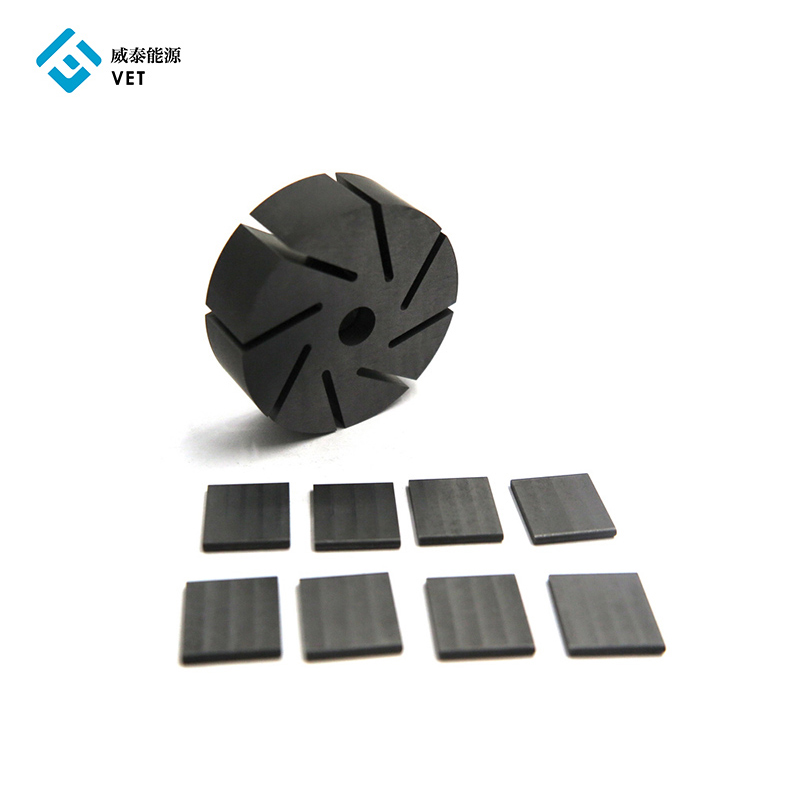

Properties :

-Outstanding thermal stability

-High mechanical strength

-Good electrical and thermal conductivity

-Excellent resistance to thermal shock and corrosion

-High material purity

-High electriccal load capacity

-Uniform temperature profile

Fields of applications:

-Vacuum furnaces

-Inert gas furnaces

-Heat treatment

(hardening, carbonization, brazing, etc.)

-Carbon fiber production

-Hard metal production

-Sintering applications

-Technical ceramic production

-CVD/PVD coasting

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Product detail pictures:

Related Product Guide:

Act 17: Police soak Yellow Vest demonstrators with water cannon, fire teargas (VIDEO) — RT World News icon bookmark-b icon bookmark icon camera icon check icon chevron down icon chevron left icon chevron right icon chevron up icon close icon v-compress | Type Butterfly Valve

Duluth takes keys to fire boat | 2” Or 3” Or 4”Manual Butterfly Valve

OEM/ODM Manufacturer Silicon Carbide Coating Processing - OEM Customized Sale Thermal Conductivity Graphite Sheet – VET Energy, The product will supply to all over the world, such as: , , ,

-

Good Wholesale VendorsGraphite Casting Mold - ...

-

High definition Silicon Carbide Coating - Chin...

-

Hot New Products Graphite Bearing - Best-Selli...

-

2017 Latest DesignCasting Ingot Mold - Graphit...

-

Ordinary Discount Pyrolytic Graphite Sheet Roll...

-

One of Hottest for Expansion Valve - High Stre...