OEM/ODM Manufacturer Silicon Carbide Coating Processing - Manufacturing Companies for China High Density High Purity Graphite Mould for Jewelry Casting – VET Energy Detail:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Manufacturing Companies for China High Density High Purity Graphite Mould for Jewelry Casting, Adhering towards the enterprise philosophy of ‘customer 1st, forge ahead’, we sincerely welcome customers from at your house and abroad to cooperate with us.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Mould, Graphite, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

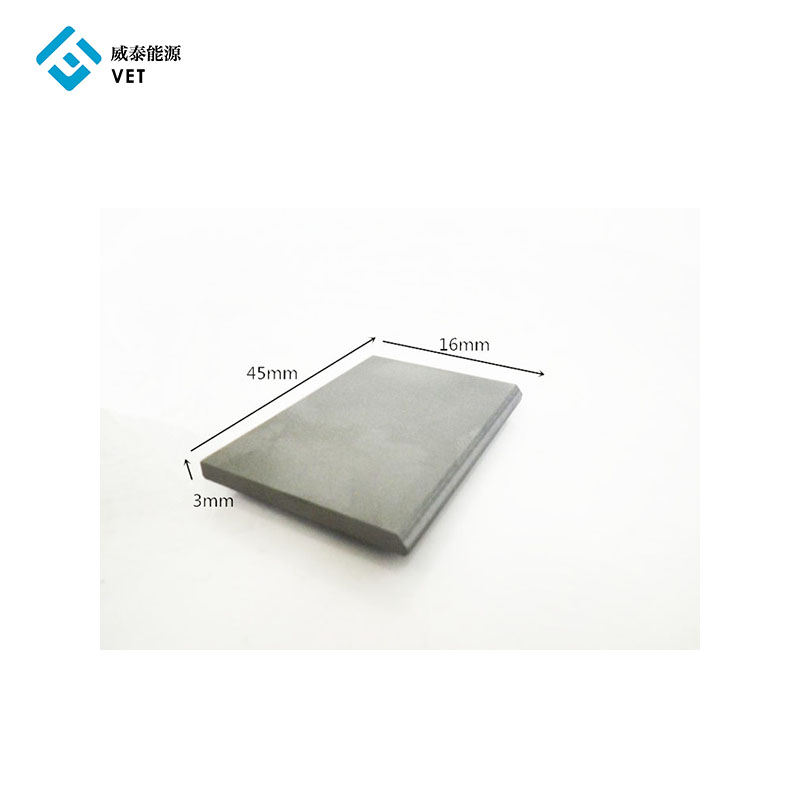

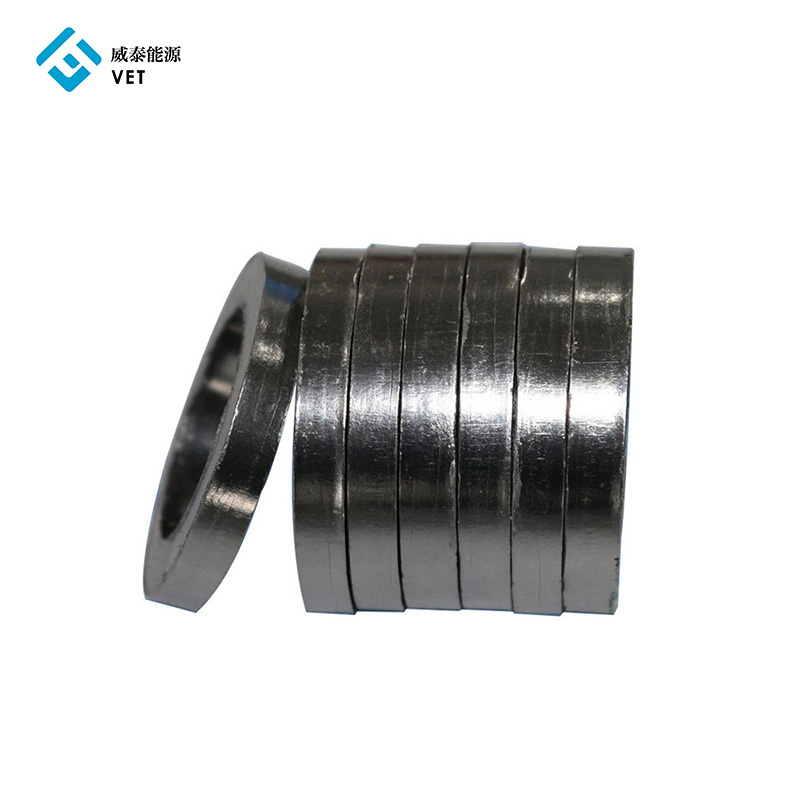

High Purity Graphite Mold Parts for Semiconductor Process

Characteristics of our graphite mold:

1. Graphite molds are one of the most heat-resistant materials at present.

2. With good thermal shock resistance, no cracks will occur when the temperature is hot and cold

3. Excellent thermal conductivity and conductive properties

4. Good lubrication and abrasion resistance

5. Chemical stability, acid and alkali resistance and corrosion resistance, not easy to react with most metals

6. Factory supply customized graphite sintering mold Easy to process, good mechanical processing performance, can machining complex shape and high precision mold

Supply Ability:

10000 Piece/Pieces per Month

Packaging & Delivery:

Packing:Standard & Strong Packing

Poly bag + Box + Carton + Pallet

Port:

Ningbo/Shenzhen/Shanghai

Lead Time:

| Quantity(Pieces) | 1 – 1000 | >1000 |

| Est. Time(days) | 15 | To be negotiated |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Product detail pictures:

Related Product Guide:

Water Cannon Market 2019 Insight by Development, Product Demand, Latest Technology, Upcoming Trends, and Growth Rate Forecast to 2024 | Fire Water Cannon

Turkish police fire water cannon at pro-Kurdish election posters: report | Fire Water Cannon

OEM/ODM Manufacturer Silicon Carbide Coating Processing - Manufacturing Companies for China High Density High Purity Graphite Mould for Jewelry Casting – VET Energy, The product will supply to all over the world, such as: , , ,

-

High Quality Graphite Block - Graphite Vane 3x...

-

Factory Cheap Hot Graphite Crucible - Online E...

-

Cheap PriceList for Expansion Valve - ODM Fact...

-

Chinese wholesale Electrical Conductive Carbon ...

-

Chinese wholesale Bushing - OEM/ODM Factory Ch...

-

New Arrival China Flexible Graphite Ring - Sil...