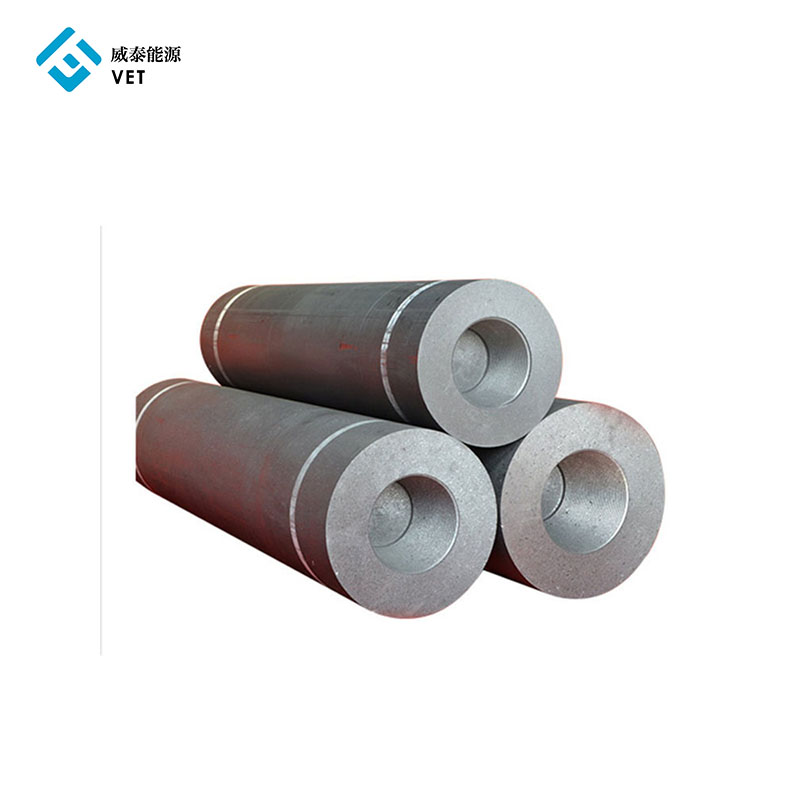

OEM/ODM Manufacturer Silicon Carbide Coating Processing - Low MOQ for China Density 1.91g Graphite Mold with Coating for Brass Casting – VET Energy Detail:

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Low MOQ for China Density 1.91g Graphite Mold with Coating for Brass Casting, With us your money in protected your organization in safe . Hope we are able to be your trustworthy supplier in China . Looking ahead for your cooperation .

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for China Graphite Die, Graphite Product, “Good quality, Good service ” is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We have been willing to establish long business relationship with all those who seek the high quality products and good service. We’ve got set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our expert experience and high quality grades will contribute to your business.

Material:

Bulk density : 1.85g.cm3

Resistance : 11-13 unm

Compressive strength : 90MPa

Flexural strength : 40 MPa

Shore hardness : 55

CET:4.8×10*6/C

Grain size: 25 um

Application:

Gold,silver,copper,precious metal casting

Useful Tips for using ingot molds:

1: Heat the graphite mold to 250c-500c to avoid any damages in the process and for a higher quality result.

Heating temperatures may vary for different materials.

2: Place scrap into graphite crucible, heat graphite crucible until metal reaches a liquefied state.

Pour molted metal into the pre-heated mold.

3: The graphite molds will last several pours depending on temperatures and types of metal that you are casing.

4: If you run into a releasing problem, you may freeze the mold to allow the ingot to release.

Note: these instructions can be used for all size graphite ingot molds.

These molds can be used for casting gold, silver, copper, platinum, aluminum, arsenic, iron, tin…

Warning: molds and metals will be extremely hot .proceed with caution.

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

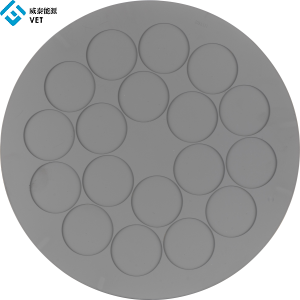

Product detail pictures:

Related Product Guide:

Dubai Airport accidentally breaks Saudi plane with water cannon salute | Fire Water Cannon

A Fire Hose May Stop a Riot. A Water Cannon Will | Rewind Roll Up Hose Reel

OEM/ODM Manufacturer Silicon Carbide Coating Processing - Low MOQ for China Density 1.91g Graphite Mold with Coating for Brass Casting – VET Energy, The product will supply to all over the world, such as: , , ,

-

Reasonable price for Graphite Ring For Pumps -...

-

Manufacturer ofVibrated Graphite Block - China...

-

2019 High quality Flexible Graphite Foil - 3 L...

-

High reputation Power Brake Booster Auxiliary P...

-

Chinese wholesale Uhp 600mm Graphite Electrode ...

-

Good quality Rigid Carbon Felt - Factory price...