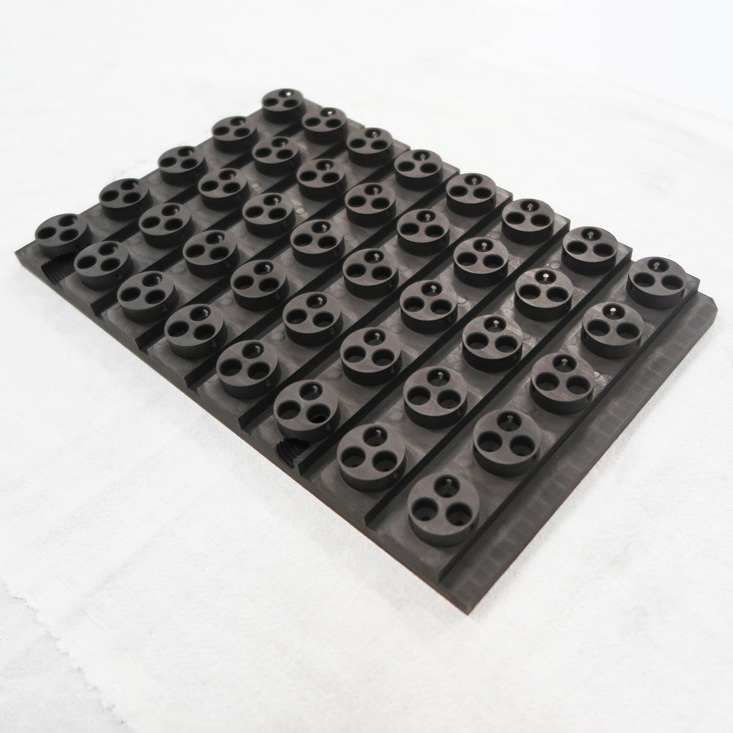

OEM Supply SiC Coating - Wholesale Dealers of Mold Graphite Ingot – VET Energy Detail:

We always continually provide you with one of the most conscientious client provider, as well as widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Wholesale Dealers of Mold Graphite Ingot, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

We always continually provide you with one of the most conscientious client provider, as well as widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Graphite, Graphite Ingot, Graphite Mold Ingot, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we’ve got the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very significantly promise:Csame top quality, better price; exact same selling price, higher quality.

Characteristics of our graphite mold:

1. Graphite molds are one of the most heat-resistant materials at present.

2. With good thermal shock resistance, no cracks will occur when the temperature is hot and cold

3. Excellent thermal conductivity and conductive properties

4. Good lubrication and abrasion resistance

5. Chemical stability, acid and alkali resistance and corrosion resistance, not easy to react with most metals

6. Factory supply customized graphite sintering mold Easy to process, good mechanical processing performance, can machining complex shape and high precision mold

Application

The graphite mold has been widely used in following aspects:

1.Continuous casting mold

2.Pressure foundry mold

3.Glass molding with die

4.Sintering mold

5.Centrifugal casting mold

6.Smelt gold, silver, jewelry……

| Grain Size (μm) |

25 | 25 | 25 | 25 |

| Bulk Density (≥g/cm3) |

1.8 | 1.8 | 1.85 | 1.85 |

| Compressive Strength (≥MPa) |

60 | 60 | 70 | 70 |

| Flexural Strength (≥MPa) |

30 | 30 | 35 | 35 |

| Porosity (≤%) |

21 | 21 | 18 | 18 |

| Specific Resistance (≤μΩm) |

12 | 12 | 12 | 12 |

| Ash Content (≤%) |

0.08 | 0.08 | 0.08 | 0.08 |

| Shore Hardness | 48 | 48 | 50 | 50 |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Product detail pictures:

Related Product Guide:

Life-saving “opioid antagonist” now in the hands of Chambers Co. Deputies Open Navigation Close Navigation Search Facebook Twitter YouTube Email | Type Butterfly Valve

Happy VFD converts military truck to fight wildfires | 2” Or 3” Or 4”Manual Butterfly Valve

OEM Supply SiC Coating - Wholesale Dealers of Mold Graphite Ingot – VET Energy, The product will supply to all over the world, such as: , , ,