OEM Supply SiC Coating - Sic Ceramic Target Silicon Carbide Sputtering Target for Coating,Sic rod,silicone rod for mechanical engineering – VET Energy Detail:

Adhering for the theory of “quality, services, performance and growth”, we have received trusts and praises from domestic and worldwide shopper for IOS Certificate China 99.5% Sic Ceramic Target Silicon Carbide Sputtering Target for Coating, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services.

Adhering for the theory of “quality, services, performance and growth”, we have received trusts and praises from domestic and worldwide shopper for China Silicon Carbide Sputtering Target, Sic Ceramic Target, We now have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our items have been strictly inspected before shipment.

Carbon / carbon composites (hereinafter referred to as “C / C or CFC”) is a kind of composite material which is based on carbon and reinforced by carbon fiber and its products (carbon fiber preform). It has both the inertia of carbon and the high strength of carbon fiber. It has good mechanical properties, heat resistance, corrosion resistance, friction damping and thermal and electrical conductivity characteristics

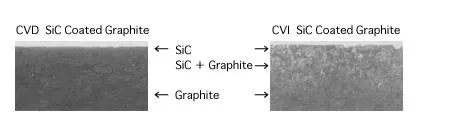

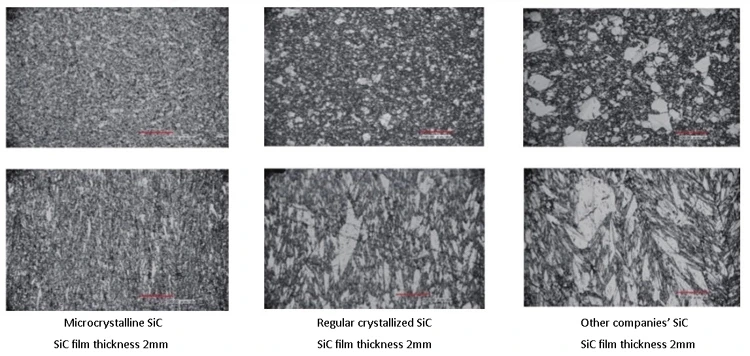

CVD-SiC coating has the characteristics of uniform structure, compact material, high temperature resistance, oxidation resistance, high purity, acid&alkali resistance and organic reagent, with stable physical and chemical properties.

Compared with high-purity graphite materials, graphite begins to oxidize at 400C, which will cause a loss of powder due to oxidation, resulting in environmental pollution to peripheral devices and vacuum chambers, and increase impurities of high-purity environment.

However, SiC coating can maintain physical and chemical stability at 1600 degrees, It is widely used in modern industry, especially in semiconductor industry.

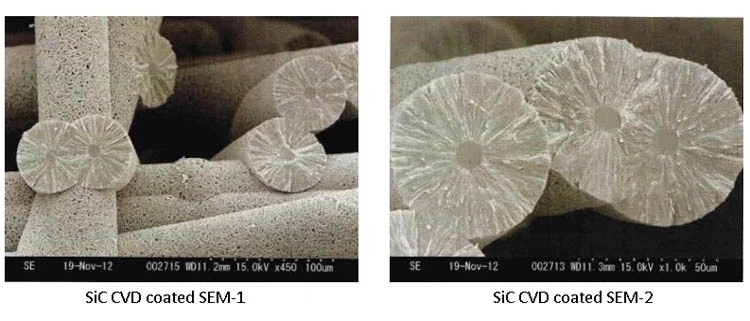

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity: made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coatings:

|

SiC-CVD |

||

| Density |

(g/cc)

|

3.21 |

| Flexural strength |

(Mpa)

|

470 |

| Thermal expansion |

(10-6/K) |

4

|

| Thermal conductivity |

(W/mK) |

300

|

Product detail pictures:

Related Product Guide:

Hong Kong: Protesters warned as police use pepper spray, water cannons | Rewind Roll Up Hose Reel

Video: Get Your First Look At The Nintendo Labo VR Kit | Fire Water Cannon

OEM Supply SiC Coating - Sic Ceramic Target Silicon Carbide Sputtering Target for Coating,Sic rod,silicone rod for mechanical engineering – VET Energy, The product will supply to all over the world, such as: , , ,