OEM Supply SiC Coating - Factory Outlets Processing Molybdenum Plate Pure Molybdenum Gasket For Mocvd – VET Energy Detail:

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Factory Outlets Processing Molybdenum Plate Pure Molybdenum Gasket For Mocvd, Our clientele mainly distributed within the North America, Africa and Eastern Europe. we are able to supply premium quality goods with the incredibly aggressive price tag.

Innovation, top quality and reliability are the core values of our company. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Molybdenum Gasket, Processing Molybdenum Plate, Pure Molybdenum, At present our sales network is growing continually, improving service quality to meet customer’s demand. If you are interested in any products and solutions , be sure to contact us at anytime. We are looking forward to forming successful business relationships with you in near future.

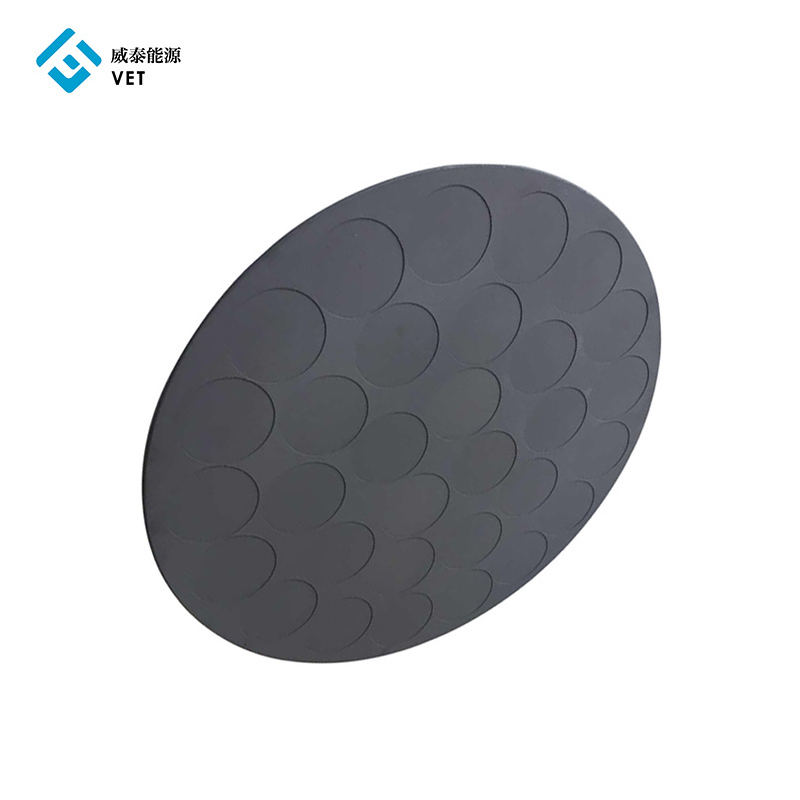

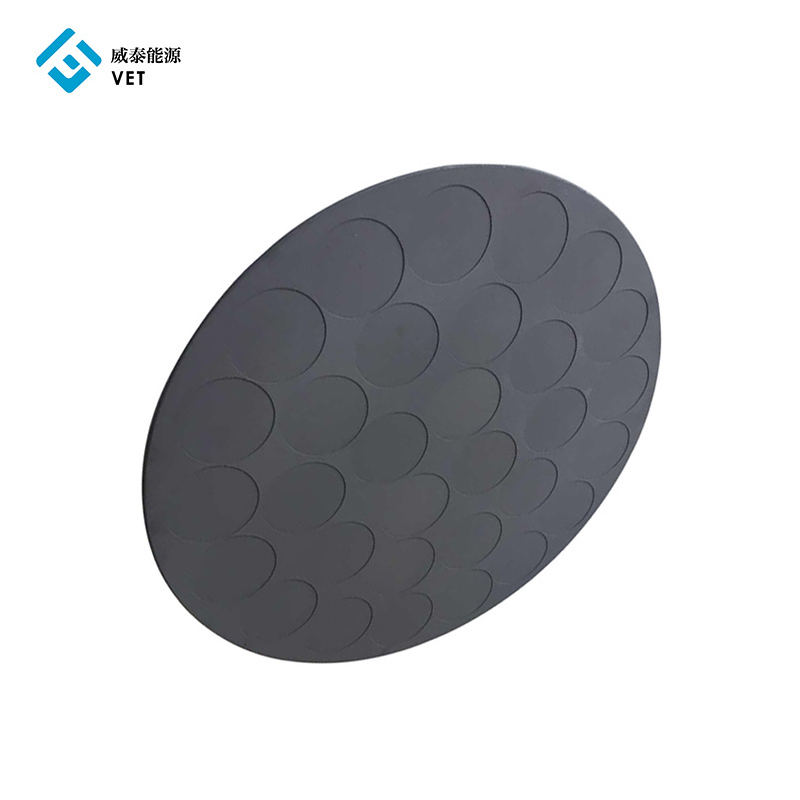

SiC coating of Graphite substrate for Semiconductor applications produces a part with superior purity and resistance to oxidizing atmosphere.

CVD SiC or CVI SiC is applied to Graphite of simple or complex design parts. Coating can be applied in varying thicknesses and to very large parts.

Features:

· Excellent Thermal Shock Resistance

· Excellent Physical Shock Resistance

· Excellent Chemical Resistance

· Super High Purity

· Availability in Complex Shape

· Usable under Oxidizing Atmosphere

Typical Properties of Base Graphite Material:

| Apparent Density: | 1.85 g/cm3 |

| Electrical Resistivity: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Shore Hardness: | 58 |

| Ash: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Product detail pictures:

Related Product Guide:

Xbox E3 2019 conference live report • Eurogamer.net | Type Butterfly Valve

Police fire tear gas to break up protest by BJP in Kolkata | Rewind Roll Up Hose Reel

OEM Supply SiC Coating - Factory Outlets Processing Molybdenum Plate Pure Molybdenum Gasket For Mocvd – VET Energy, The product will supply to all over the world, such as: , , ,

-

Chinese Professional Graphite Mold - Chinese P...

-

Chinese wholesale Electrical Conductive Carbon ...

-

Low price for YBCO Superconductor - New Fashio...

-

Hot sale Graphite Rotor And Impeller - Isotrop...

-

Factory wholesale Electronic Power Brake Booste...

-

Cheap price Electric Brake Vacuum Pump In Diaph...