“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for OEM Supply Anti-Oxidation Graphite Crucible & Crystallizer, We welcome new and aged prospects from all walks of everyday living to get hold of us for foreseeable future small business relationships and mutual results!

“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for China Anti-Oxidation and Graphite Crucible, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we have been working hard to provide you the wholehearted service and willing to present you the most competitive price in the market

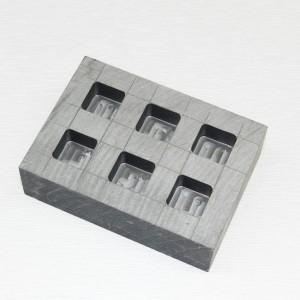

Graphite crystallizer refers to a graphite product used in a continuous casting mold. Metal continuous casting technology is a new technology for directly forming molten metal through a continuous casting mold. Because it is directly formed without rolling, it avoids secondary heating of the metal, so it can save a lot of energy. Compared with other graphite materials, continuous casting graphite is characterized by fine particles, uniform texture, large bulk density, low porosity and high strength.

Material

| Bulk density | 1.80g/cm3 |

| Shore hardness | 55 |

| CET | 4.8×10*6/C |

| Resistance | 11-13 unm |

| Flexural strength | 40 MPa |

| Compressive strength | 90MPa |

Application

Gold,silver,copper,precious metal casting

Useful Tips for using ingot molds:

1: Heat the graphite mold to 250c-500c to avoid any damages in the process and for a higher quality result.

Heating temperatures may vary for different materials.

2: Place scrap into graphite crucible, heat graphite crucible until metal reaches a liquefied state.

Pour molted metal into the pre-heated mold.

3: The graphite molds will last several pours depending on temperatures and types of metal that you are casing.

4: If you run into a releasing problem, you may freeze the mold to allow the ingot to release.

Note: these instructions can be used for all size graphite ingot molds.

These molds can be used for casting gold, silver, copper, platinum, aluminum, arsenic, iron, tin…

Warning: molds and metals will be extremely hot .proceed with caution.

Mobile/Wechat/Whatsapp: 86-189 1159 6362