With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for ODM Factory Chemical Smelting Graphite Heater for Industrial Smelting, If you’re fascinated in any of our objects, remember to really don’t wait to make contact with us and go ahead and take first step to construct up a prosperous small business connection.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for China Smelting and Plate Heat Exchanger, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

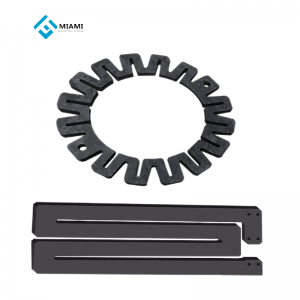

Graphite heater:

The graphite heater components are used in the high temperature furnace with temperature reached 2200 degree at vacuum environment and 3000 degree in the deoxidized and inserted gas environment.

Main features of graphite heater:

1. uniformity of heating structure.

2. good electrical conductivity and high electrical load.

3. corrosion resistance.

4. inoxidizability.

5. high chemical purity.

6. high mechanical strength.

The advantage is energy efficient, high value and low maintenance.

We can produce anti-oxidation and long life span graphite crucible, graphite mold and all parts of graphite heater.

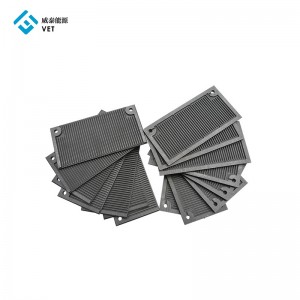

Main parameters of graphite heater:

| Technical Specification |

VET-M3 |

| Bulk Density (g/cm3) |

≥1.85 |

| Ash Content (PPM) |

≤500 |

| Shore Hardness |

≥45 |

| Specific Resistance (μ.Ω.m) |

≤12 |

| Flexural Strength (Mpa) |

≥40 |

| Compressive Strength (Mpa) |

≥70 |

| Max. Grain Size (μm) |

≤43 |

| Coefficient of Thermal Expansion Mm/°C |

≤4.4*10-6 |

Graphite heater for electric furnace has properties of heat resistance, oxidation resistance, good electrical conductivity and better mechanical intensity. We can machine various types of graphite heater according to customers’ designs.

FAQ

Q: Are you trading company or manufacturer?

A:We are an more than 10 vears factory with iso9001 certificacted

Q:How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock,or 10-15 days if the goods are not in stock, it is according to your quantity.

Q: How can Iget the sample to check your quality?

A: After price confirmation, you can require for samples to check our product’s quality. If you just need a blank sample to check the design and quality,we will provide you sample for free as long as you afford the express freight.

Q:What is your terms of payment?

A: We accept payment by Western union,Pavpal,Alibaba,T/TL/Cetc..for bulk order,we do 30% deposit balance before shipment.

if you have another question,pls feel free to contact us as below

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for ODM Factory Chemical Smelting Graphite Heater for Industrial Smelting, If you’re fascinated in any of our objects, remember to really don’t wait to make contact with us and go ahead and take first step to construct up a prosperous small business connection.

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for ODM Factory Chemical Smelting Graphite Heater for Industrial Smelting, If you’re fascinated in any of our objects, remember to really don’t wait to make contact with us and go ahead and take first step to construct up a prosperous small business connection.

ODM Factory China Smelting and Plate Heat Exchanger, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.