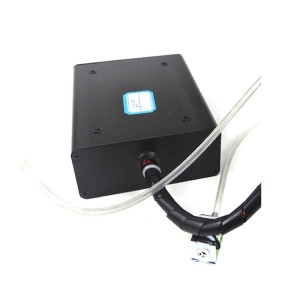

vet-china ikubweretsa Boti lamakono la Contiguous Wafer Boat lomwe linapangidwira m'badwo wotsatira wopanga ma semiconductor. Bwato lopangidwa mwalusoli limapereka kulondola kosayerekezeka pakugwira zowotcha, kuwonetsetsa kuti zikuyenda bwino komanso kuchepetsa kwambiri chiwopsezo cha kuwonongeka pakukonza.

Womangidwa ndi zida zapamwamba kwambiri, Boti la Contiguous Wafer limadzitamandira kukhazikika kwamafuta komanso kukana kwapadera kwamankhwala, kupangitsa kuti likhale loyenera kutentha kwambiri komanso malo owopsa amankhwala. Kapangidwe kake katsopano kamatsimikizira kuti zowotcherera zimasungidwa motetezeka komanso zolumikizidwa bwino, kukhathamiritsa momwe zimagwirira ntchito ndikuwonjezera kupanga bwino.

Bwato laling'ono ili laling'ono limapangidwa kuti likwaniritse zofunikira za nsalu zamakono za semiconductor, zothandizira kukula kwake ndi masanjidwe osiyanasiyana. Mwa kuphatikiza Contiguous Wafer Boat kuchokera ku vet-china mumzere wanu wopanga, mutha kuyembekezera kuchita bwino, kuchepetsa nthawi yopumira, komanso kuchuluka kwa zokolola.

Dziwani kusiyana kwake ndi kudzipereka kwa vet-china pazabwino komanso zatsopano, popereka zinthu zomwe zimakankhira malire opanga ma semiconductor. Sankhani Boti la Contiguous Wafer ndikukwezera luso lanu lopangira zopindika kuti zikhale zazitali zatsopano.

Katundu wa recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) ndi chinthu chochita bwino kwambiri chokhala ndi kuuma kwachiwiri kwa diamondi, chomwe chimapangidwa pa kutentha kwambiri kuposa 2000 ℃. Imakhala ndi zinthu zambiri zabwino kwambiri za SiC, monga mphamvu ya kutentha kwambiri, kukana kwa dzimbiri, kukana kwa okosijeni kwabwino, kukana kwamphamvu kwamafuta ndi zina zotero.

● Makina abwino kwambiri. Recrystallized silicon carbide imakhala ndi mphamvu zambiri komanso kuuma kuposa mpweya wa kaboni, kukana kwakukulu, kumatha kusewera bwino m'malo otentha kwambiri, kumatha kusewera bwino pakanthawi kochepa. Kuonjezera apo, imakhalanso ndi kusinthasintha kwabwino ndipo sikuwonongeka mosavuta ndi kutambasula ndi kupindika, zomwe zimathandizira kwambiri ntchito yake.

● Kulephera kwa dzimbiri. Recrystallized pakachitsulo carbide ali mkulu dzimbiri kukana zosiyanasiyana TV, angalepheretse kukokoloka kwa zosiyanasiyana zowononga TV, akhoza kukhalabe mawotchi katundu wake kwa nthawi yaitali, ali adhesion amphamvu, kotero kuti ali ndi moyo wautali utumiki. Kuonjezera apo, ilinso ndi kukhazikika kwabwino kwa kutentha, imatha kusintha kusintha kwa kutentha, kusintha ntchito yake.

● Kuimba sikuchepa. Chifukwa njira ya sintering simachepa, palibe kupsinjika kotsalira komwe kungayambitse kusinthika kapena kusweka kwa chinthucho, ndipo magawo omwe ali ndi mawonekedwe ovuta komanso olondola kwambiri amatha kukonzekera.

| 重结晶碳化硅物理特性 Zakuthupi za Recrystallized Silicon Carbide | |

| 性质 / Katundu | 典型数值 / Mtengo Wofanana |

| 使用温度/ Kutentha kogwira ntchito (°C) | 1600 ° C (ndi mpweya), 1700 ° C (kuchepetsa chilengedwe) |

| SiC含量/ Zolemba za SiC | 99.96% |

| 自由Si 含量/ Zaulere za Si | <0.1% |

| 体积密度/Kuchulukana kwakukulu | 2.60-2.70 g / masentimita3 |

| 气孔率/ Kuwoneka kwa porosity | < 16% |

| 抗压强度/ Kupsinjika kwamphamvu | > 600MPa |

| 常温抗弯强度/Kuzizira kopinda mphamvu | 80-90 MPa (20°C) |

| 高温抗弯强度Mphamvu yopindika yotentha | 90-100 MPa (1400°C) |

| 热膨胀系数/ Kukula kwa kutentha pa 1500°C | 4.70 10-6/°C |

| 导热系数/Thermal conductivity @ 1200 ° C | 23W/m•K |

| 杨氏模量/ Elastic modulus | 240 GPA |

| 抗热震性/ Kutentha kwamphamvu kukana | Zabwino kwambiri |

Mbiri ya VET Energy ndiwopanga weniweni wa makonda graphite ndi silicon carbide mankhwala ndi CVD zokutira,akhoza kuperekazosiyanasiyanamagawo makonda a semiconductor ndi photovoltaic makampani. OGulu laukadaulo la ur limachokera ku mabungwe apamwamba ofufuza zapakhomo, limatha kupereka mayankho aukadaulozanu.

Timapitiriza kupanga njira zapamwamba kuti tipereke zipangizo zamakono,ndiapanga ukadaulo wapatent, womwe ungapangitse kulumikizana pakati pa zokutira ndi gawo lapansi kukhala lolimba komanso kuti lisasokonezeke.

| CVD SiC薄膜基本物理性能 Zida zoyambira za CVD SiCzokutira | |

| 性质 / Katundu | 典型数值 / Mtengo Wofanana |

| 晶体结构 / Kapangidwe ka Crystal | FCC β gawo多晶,主要為(111)取向 |

| 密度 / Kuchulukana | 3.21g/cm³ |

| 硬度 / Kuuma | 2500 维氏硬度 (500g katundu) |

| 晶粒大小 / Mbewu SiZe | 2 ~ 10μm |

| 纯度 / Chemical Purity | 99.99995% |

| 热容 / Kutentha Kwambiri | 640 jkg-1·K-1 |

| 升华温度 / Sublimation Kutentha | 2700 ℃ |

| 抗弯强度 / Flexural Mphamvu | 415 MPa RT 4-mfundo |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt bend, 1300 ℃ |

| 导热系数 / ThermalConductivity | 300Wm-1·K-1 |

| 热膨胀系数 Kukula kwa Matenthedwe (CTE) | 4.5 × 10-6K-1 |

Takulandirani ndi manja awiri kuti mudzacheze fakitale yathu, tikambiranenso!

-

Kutentha kwakukulu kodzikulitsa kudziletsa kusindikiza gr...

-

Uav Pem Hydrogen Fuel Cell Portable Backup Powe...

-

Magetsi Vacuum Pump Mphamvu Brake Booster Auxili...

-

Mkulu kachulukidwe graphite bushing vacuum mpope graph ...

-

1000w Hydrogen Fuel Cell Stack Yomwe Ingagwiritsidwe Ntchito...

-

Graphite Mold