-

Progress and economic analysis of hydrogen production by electrolysis of solid oxides

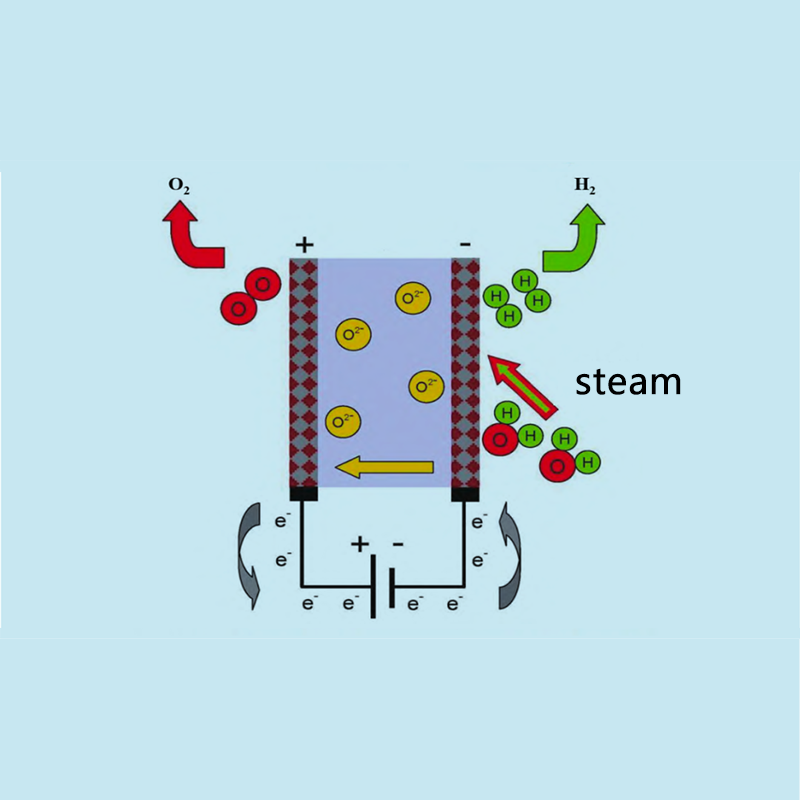

Progress and economic analysis of hydrogen production by electrolysis of solid oxides Solid oxide electrolyzer (SOE) uses high-temperature water vapor (600 ~ 900°C) for electrolysis, which is more efficient than alkaline electrolyzer and PEM electrolyzer. In the 1960s, the United States and Germa...Read more -

International hydrogen | BP released 2023 “world energy outlook”

On January 30, British Petroleum (BP) released the 2023 “World Energy Outlook” report, emphasizing that fossil fuels in the short term is more important in the energy transition, but the global energy supply shortage, carbon emissions continue to increase and other factors are expecte...Read more -

Progress and economic analysis of ion exchange membrane (AEM) hydroelectrolysis for hydrogen production

AEM is to some extent a hybrid of PEM and traditional diaphragm based lye electrolysis. The principle of AEM electrolytic cell is shown in Figure 3. At the cathode, water is reduced to produce hydrogen and OH -. OH — flows through the diaphragm to the anode, where it recombines to produce o...Read more -

Proton exchange membrane (PEM) electrolytic water hydrogen production technology progress and economic analysis

In 1966, General Electric Company developed water electrolytic cell based on proton conduction concept, using polymer membrane as electrolyte. PEM cells were commercialized by General Electric in 1978. Currently, the company produces fewer PEM cells, mainly because of its limited hydrogen product...Read more -

Progress of hydrogen production technology and economic analysis – Hydrogen production in alkaline electrolytic cell

Alkaline cell hydrogen production is a relatively mature electrolytic hydrogen production technology. Alkaline cell is safe and reliable, with a life span of 15 years, and has been widely used commercially. The working efficiency of alkaline cell is generally 42% ~ 78%. In the past few years, alk...Read more -

JRF-H35-01TA Carbon fiber special hydrogen storage tank regulating valve

1.product presentation The JRF-H35-01TA gas cylinder pressure relief valve is a gas supply valve specially designed for small hydrogen supply systems such as 35MPa. See Fig. 1, Figure 2 for the device, schematic diagram and physical objects. JRF-H35-01TA cylinder pressure relief valve adopts inte...Read more -

Instructions for air charging of carbon fiber cylinder and regulator valve

1. Prepare the pressure valve and carbon fiber cylinder 2. Install the pressure valve on the carbon fiber cylinder and tighten it clockwise, which can be reinforced with an adjustable wrench according to the actual 3. Screw the matching charging pipe onto the hydrogen cylinder, with the th...Read more -

Instructions for air charging of carbon fiber cylinder and regulator valve

1. Prepare the pressure valve and carbon fiber cylinder 2. Install the pressure valve on the carbon fiber cylinder and tighten it clockwise, which can be reinforced with an adjustable wrench according to the actual 3. Screw the matching charging pipe onto the hydrogen cylinder, with the th...Read more -

The world’s first single reactor system with rated power exceeding 132kW

Parameter Unit Value 系统外形尺寸 System overall size mm 1033*770*555 产品净重 Product net weight kg 258 额定输出功率 Rated output power kW 132 电堆体积功率密度 Volume power density of stack kW/L 3.6 系统质量功率密度 Mass power density of system W/kg ...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur