-

How much do you know about graphite bearing bushing?

Innovative technology to improve the performance of industrial equipment Graphite bearing bushings are bearing bushings made of graphite materials. It is widely used in industrial fields to improve the operation efficiency and reliability of equipment. It has excellent friction and wear resistanc...Read more -

Rolling process of graphite bipolar plate

The bipolar plate, also known as the collector plate, is one of the important components of the fuel cell. It has the following functions and properties: separating fuel and oxidizer, preventing gas penetration; Collect and conduct current, high conductivity; The flow channel designed and process...Read more -

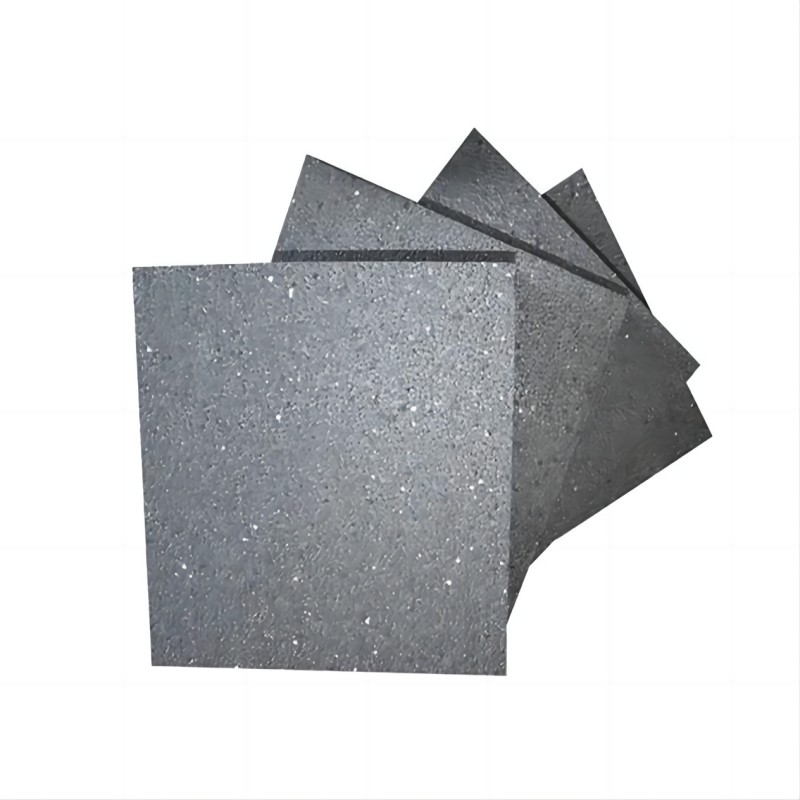

Characteristics and uses of graphite plates

Graphite plate has good electrical conductivity, high temperature resistance, acid resistance, alkali corrosion resistance, easy processing. Therefore, it is widely used in metallurgy, chemical industry, electrochemistry and other industries. One of the main uses of graphite plates is in the semi...Read more -

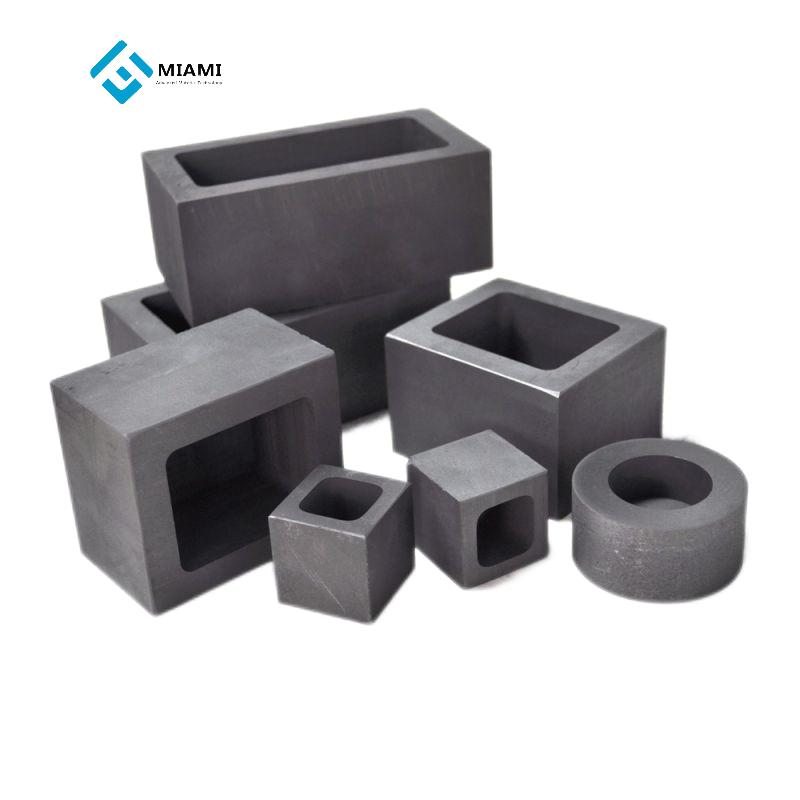

What is the compressive strength of graphite mold?

With the rapid development of industry, graphite has been regarded as one of the important industrial mineral raw materials at home and abroad, especially in recent years, with the development of science and technology, graphite processing products have played an important role in all walks of li...Read more -

How does high purity graphite evolve into graphite products?

High purity graphite refers to the carbon content of graphite. 99.99%, widely used in metallurgical industry of high-grade refractory materials and coatings, military industrial fire materials stabilizer, light industry pencil lead, electrical industry carbon brush, battery industry electrode, fe...Read more -

Characteristics of graphite mold and processing equipment

In recent years, graphite mold in the modern industrial application industry continues to expand its position, this time is different from the past, the current graphite mold is already a trend in the future. First, wear resistance The reason why graphite molds generally fail due t...Read more -

The correct maintenance method of graphite boat

Before entering the PE furnace tube, check whether the graphite boat is in good condition again. It is recommended to pretreat (saturated) at normal time, it is recommended not to pretreat in empty boat state, it is best to install fake or waste tablets; Although the operation procedure is longer...Read more -

How to take graphite rod?

The thermal conductivity and electrical conductivity of graphite rods are quite high, and their electrical conductivity is 4 times higher than that of stainless steel, 2 times higher than that of carbon steel, and 100 times higher than that of general non-metals. Its thermal conductivity not only...Read more -

How to use high purity graphite mold correctly

High purity graphite mold is one of the main products of our company, but also by virtue of reliable quality, durable nature, has won the recognition of many users. However, there are still some people in the market who do not understand the high-purity graphite mold, and in the process of using ...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur