-

The application prospects of graphite bearings in the field of seals

Seals play a key role in the industrial field, and graphite bearings, as an important seal, are gradually showing broad application prospects. Especially in fields such as semiconductor manufacturing, the application of graphite bearings has unique advantages. Graphite bearings are bearings made ...Read more -

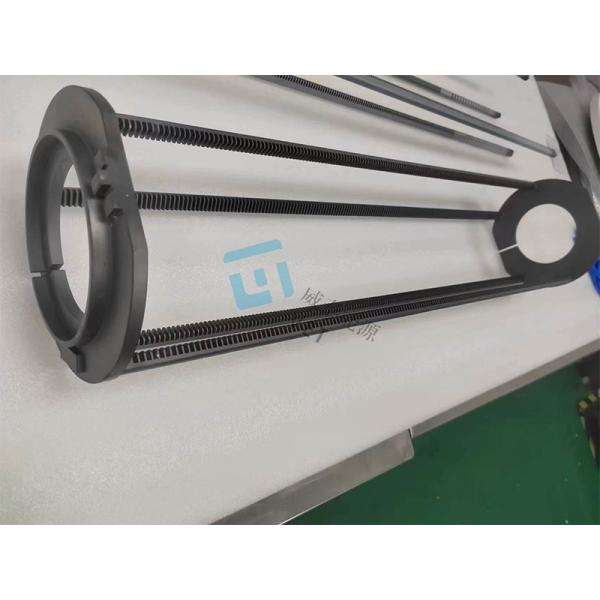

The application prospects of graphite rings in the field of seals

Seals play a key role in many industrial sectors, from automotive manufacturing to the aerospace, chemical and semiconductor industries, which all require efficient and reliable sealing solutions. In this regard, graphite rings, as an important sealing material, are gradually showing broad applic...Read more -

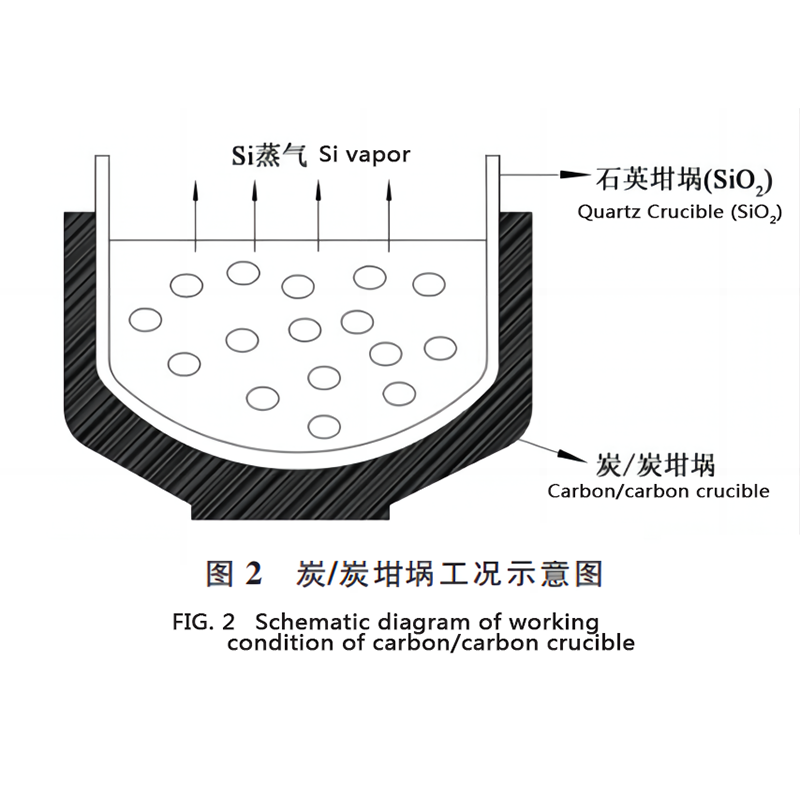

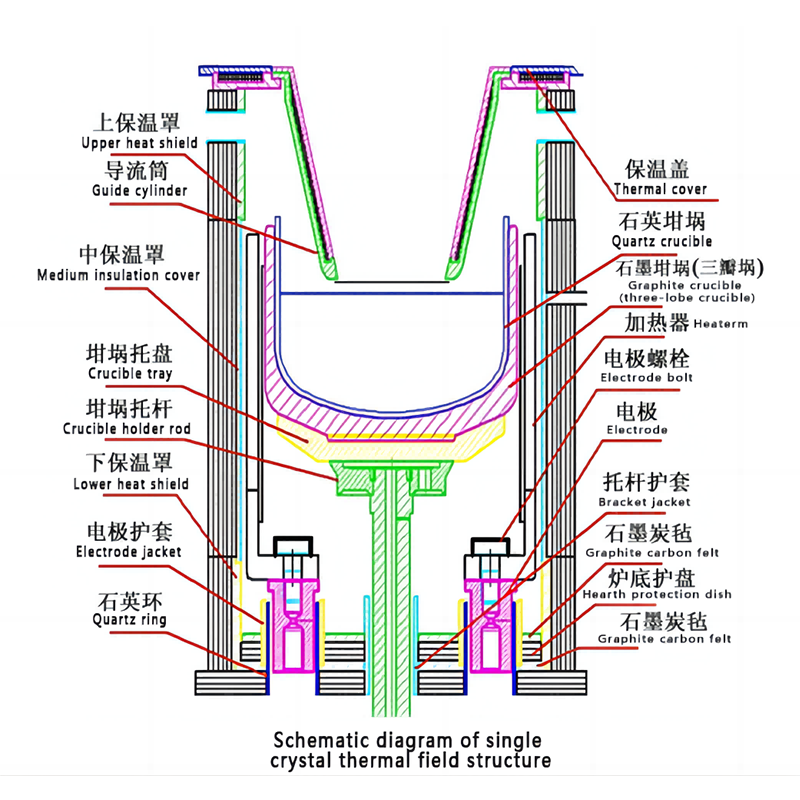

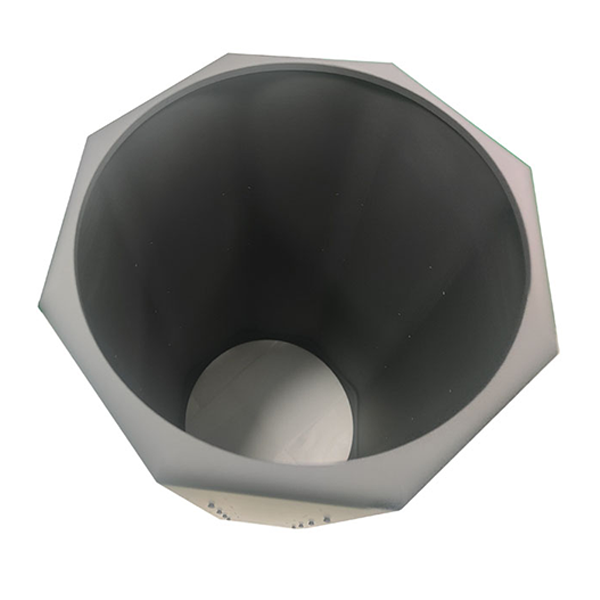

Application and research progress of SiC coating in carbon/carbon thermal field materials for monocrystalline silicon-2

1 Application and research progress of silicon carbide coating in carbon/carbon thermal field materials 1.1 Application and research progress in crucible preparation In the single crystal thermal field, the carbon/carbon crucible is mainly used as a carrying vessel for ...Read more -

Application and research progress of SiC coating in carbon/carbon thermal field materials for monocrystalline silicon-1

Solar photovoltaic power generation has become the world's most promising new energy industry. Compared with polysilicon and amorphous silicon solar cells, monocrystalline silicon, as a photovoltaic power generation material, has a high photoelectric conversion efficienc...Read more -

Silicon carbide ceramic products: an important part of the semiconductor industry

In the semiconductor industry, silicon carbide ceramic products play an important role. Its unique properties and characteristics make it a key material in the semiconductor manufacturing process. This paper will explore the importance of silicon carbide ceramic products...Read more -

Silicon carbide crystal boat: the new weapon of semiconductor industry

With the continuous advancement of science and technology, the semiconductor industry has an increasing demand for high-performance, high-efficiency materials. In this field, silicon carbide crystal boat has become the focus of attention for its unique characteristics an...Read more -

Press-free sintering of silicon carbide: a new era of high temperature material preparation

Material properties under friction, wear and high temperature environments are increasingly demanding, and the emergence of press-free sintered silicon carbide materials provides us with an innovative solution. Pressureless sintered silicon carbide is a ceramic material formed by sintering silico...Read more -

Reaction-sintered silicon carbide: a popular choice for high-temperature materials

In high temperature applications, the choice of materials is critical. Among them, the reaction-sintered silicon carbide material has become a popular choice due to its excellent performance. Reaction-sintered silicon carbide is a ceramic material formed by the reaction sintering of carbon and si...Read more -

The role of graphite crucible in metallurgical field

Graphite crucible is an important tool widely used in the field of metallurgy. It is made of a high purity graphite material with excellent high temperature resistance and chemical stability, so it plays a key role in the metallurgical process. First of all, graphite cru...Read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur