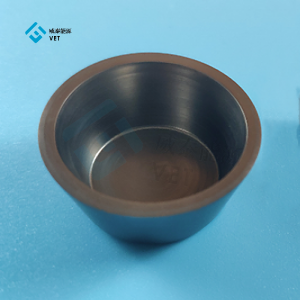

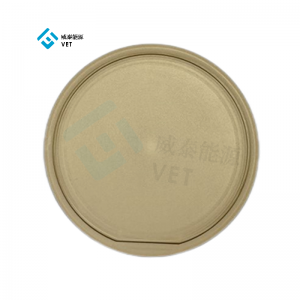

Njirimara nke silicon carbide recrystallized

silicon carbide recrystallized (R-SiC) bụ ihe na-arụ ọrụ dị elu nke nwere ike nke abụọ na diamond, nke a na-etolite na okpomọkụ dị elu karịa 2000 ℃. Ọ na-ejigide ọtụtụ ihe ndị mara mma nke SiC, dị ka ike okpomọkụ dị elu, nguzogide corrosion siri ike, nguzogide oxidation magburu onwe ya, ezigbo nkwụsị ọkụ ọkụ na ihe ndị ọzọ.

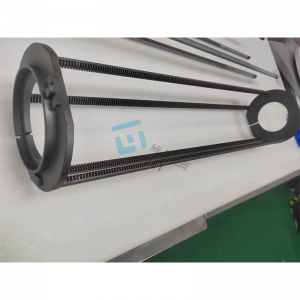

● Magburu onwe n'ibu Njirimara. silicon carbide recrystallized nwere ike dị elu na isi ike karịa eriri carbon, mmetụta dị elu na-eguzogide, nwere ike ịrụ ọrụ dị mma na gburugburu okpomọkụ dị oke egwu, nwere ike ịrụ ọrụ counterbalance ka mma n'ọnọdụ dị iche iche. Tụkwasị na nke ahụ, ọ na-enwekwa mgbanwe dị mma na ọ dịghị emebi ngwa ngwa site na ịgbatị na ịgbatị, nke na-eme ka arụmọrụ ya dịkwuo mma.

● Nnukwu nguzogide corrosion. Carbide silicon recrystallized nwere nnukwu ihe mgbochi corrosion na-eguzogide ụdị mgbasa ozi dị iche iche, nwere ike igbochi mmebi nke mgbasa ozi dị iche iche na-emebi emebi, nwere ike ịnọgide na-arụ ọrụ ya ruo ogologo oge, nwee nkwekọ siri ike, ka o wee nwee ogologo ndụ ọrụ. Tụkwasị na nke ahụ, ọ na-enwekwa nkwụsi ike nke okpomọkụ dị mma, nwere ike ime mgbanwe na mgbanwe mgbanwe okpomọkụ, melite mmetụta ngwa ya.

● Ime ihe adịghị ebelata. N'ihi na usoro nkwụsịtụ adịghị ebelata, ọ dịghị nrụgide fọdụrụnụ ga-eme ka nrụrụ ma ọ bụ mgbawa nke ngwaahịa ahụ, na akụkụ ndị nwere ọdịdị dị mgbagwoju anya na nkenke dị elu nwere ike ịkwadebe.

| 重结晶碳化硅物理特性 Njirimara anụ ahụ nke Silicon Carbide recrystallized | |

| 性质 / Ihe onwunwe | 典型数值 / Uru a na-ahụkarị |

| 使用温度/ Okpomọkụ na-arụ ọrụ (°C) | 1600°C (ya na oxygen), 1700°C (mbelata gburugburu ebe obibi) |

| SiC含量/ SiC ọdịnaya | > 99.96% |

| 自由Si含量/ Free Si ọdịnaya | <0.1% |

| 体积密度/Nnukwu njupụta | 2.60-2.70 g / cm3 |

| 气孔率/ O doro anya na porosity | <16% |

| 抗压强度/ ike mkpakọ | > 600MPa |

| 常温抗弯强度/Ike na-ehulata oyi | 80-90 MPa (20°C) |

| 高温抗弯强度Ike na-ehulata ọkụ | 90-100 MPa (1400°C) |

| 热膨胀系数/ Mgbasa ọkụ @1500°C | 4.70 10-6/°C |

| 导热系数/Nrụpụta okpomọkụ @1200°C | 23W/m•K |

| 杨氏模量/ Ngbanwe modulu | 240 GPA |

| 抗热震性/ Thermal ujo eguzogide | Dị oke mma |

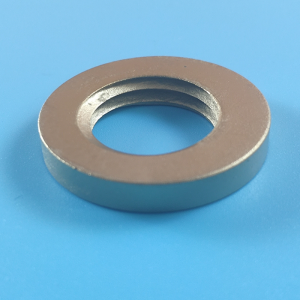

VET Energy bụ nkeezigbo onye na-emepụta ngwaahịa graphite na silicon carbide nwere mkpuchi CVD,nwere ike inyedị iche icheakụkụ ahaziri maka semiconductor na fotovoltaic ụlọ ọrụ. Our teknuzu otu si n'elu ụlọ nnyocha ụlọ ọrụ, nwere ike na-enye ndị ọzọ ọkachamara ihe ngwọtamaka gị.

Anyị na-aga n'ihu na-emepụta usoro dị elu iji nye ihe ndị dị elu karị,naarụpụtala nkà na ụzụ nwere ikike pụrụ iche, nke nwere ike ime ka njikọ dị n'etiti mkpuchi na mkpụrụ ahụ sie ike ma ghara ịdị na-apụ apụ.

| CVD SiC薄膜基本物理性能 Njirimara anụ ahụ bụ isi nke CVD SiCmkpuchi | |

| 性质 / Ihe onwunwe | 典型数值 / Uru a na-ahụkarị |

| 晶体结构 / Crystal Structure | FCC β oge多晶,主要为(111) 取向 |

| 密度 / Njupụta | 3.21g/cm³ |

| 硬度 / Isi ike | 2500 维氏硬度 (ibu 500g) |

| 晶粒大小 / ọka SiZe | 2 ~ 10μm |

| 纯度 / Chemical ịdị ọcha | 99.99995% |

| 热容 / Okpomọkụ Ike | 640 nk-1· K-1 |

| 升华温度 / Sublimation okpomọkụ | 2700 ℃ |

| 抗弯强度 / Ike Flexural | 415 MPa RT 4-isi |

| 杨氏模量 Modul nke Young's | 430 Gpa 4pt ekwe, 1300 ℃ |

| 导热系数 / ThermalOmume omume | 300W·m-1· K-1 |

| 热膨胀系数 Mgbasawanye okpomọkụ (CTE) | 4.5 × 10-6K-1 |

Ji obi ụtọ nabata gị ileta ụlọ ọrụ anyị, ka anyị nwee mkparịta ụka ọzọ!