VET-China is proud to launch Hydrogen Fuel Cell PEM Membrane Electrode Assemblies. This revolutionary product combines advanced technology to provide users with high-quality, reliable clean energy solutions. As a leader in the field of hydrogen energy, VET-China's products are in the leading position in energy conversion and storage, providing users with excellent energy efficiency and environmental performance.

Specifications of membrane electrode assembly:

| Thickness | 50 μm. |

| Sizes | 5 cm2, 16 cm2, 25 cm2, 50 cm2 or 100 cm2 active surface areas. |

| Catalyst Loading | Anode = 0.5 mg Pt/cm2.Cathode = 0.5 mg Pt/cm2. |

| Membrane electrode assembly types | 3-layer, 5-layer, 7-layer (so before ordering, please clarify how many layers MEA you prefer, and also provide the MEA drawing). |

The function of fuel cell MEA:

-Separating reactants: prevents direct contact between hydrogen and oxygen.

-Conducting protons: allows protons (H+) to pass from the anode through the membrane to the cathode.

-Catalyzing reactions: Promotes hydrogen oxidation at the anode and oxygen reduction at the cathode.

-Generating current: produces electron flow through electrochemical reactions.

-Managing water: maintains proper water balance to ensure continuous reactions.

VET Energy has independently developed high-performance MEAs, through advanced catalysts and MEA production processes, it can have:

current density: 2400mA/cm2@0.6V.

power density: 1440mW/ cm2@0.6V.

The main structure of fuel cell MEA:

a) Proton Exchange Membrane (PEM): a special polymer membrane in the center.

b) Catalyst Layers: on both sides of the membrane, usually composed of precious metal catalysts.

c) Gas Diffusion Layers (GDL): on the outer sides of the catalyst layers, typically made of fiber materials.

-

Pem Fuel Cell Stack 24v Outdoor Pemfc Hydrogen ...

-

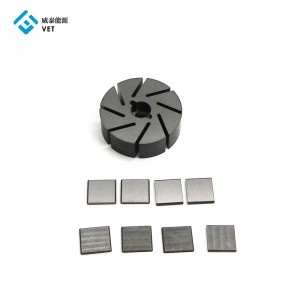

High Quality for China High Conductivity Carbon...

-

Lowest Price for High Thermal Conductivity Grap...

-

High definition China Direct Factory Thickness ...

-

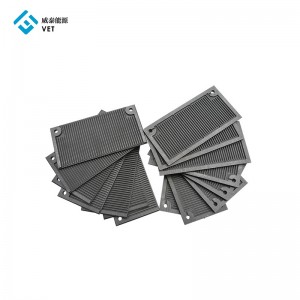

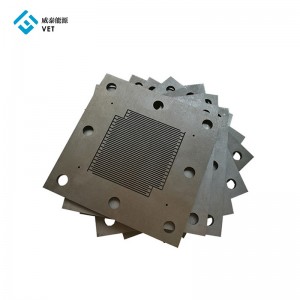

OEM/ODM Manufacturer Carbon Graphite Bipolar Pl...

-

Factory Cheap High Conductivity Graphite Bipola...