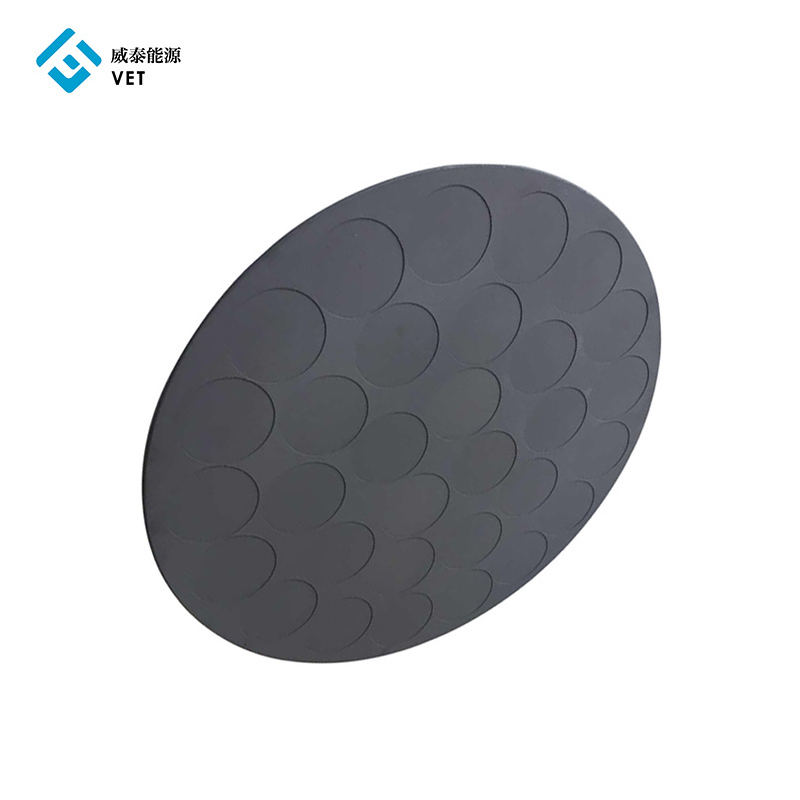

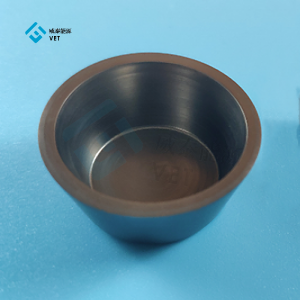

Lub VET EnergySiC Coated MOCVD Susceptoryog cov khoom siv ua haujlwm siab ua haujlwm rau kev ua haujlwm zoo ib yam thiab txhim khu kev qha hauv wafer ua daim ntawv thov. Featuring tus superiorSiC txheej, nws muaj qhov tshwj xeeb kub tsis kam, thermal uniformity, thiab corrosion kuj. Zoo tagnrho rauCov khoom siv MOCVD, qhov nosilicon carbide coated susceptorxyuas kom zoowaferkev loj hlob thiab ncua cov khoom siv lifespan.

Khoom nta:

1. Kub-kub oxidation tsis kam mus txog 1700 ℃: Peb SiC txheej muab tshwj xeeb thermal stability, txawm nyob rau hauv qhov xav tau tshaj plaws MOCVD ib puag ncig.

2. High purity thiab thermal uniformity: Lub silicon carbide susceptor guarantees tsawg impurities thiab cov cua kub zoo ib yam thoob plaws lub wafer, kom ntseeg tau superior crystal zoo.

3. Zoo heev corrosion kuj: Resistant rau acids, alkalis, ntsev, thiab organic reagents, peb susceptor tswj nws kev ncaj ncees nyob rau hauv ntau yam tshuaj ib puag ncig.

4. High hardness, ntom ntom, thiab cov khoom zoo: Cov khoom no ua rau lub neej ua haujlwm ntev dua thiab ua kom muaj zog.

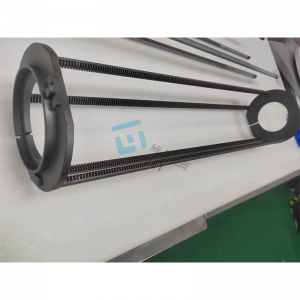

Peb CVD silicon carbide coated Cov Khoom Siv thiab Kev Siv

MOCVD susceptors xa cov txiaj ntsig tseem ceeb hauv kev tsim khoom semiconductor. SiC txheej txhim kho wafer zoo, txo qhov tsis xws luag, thiab txhim kho kev ua haujlwm zoo. VET Energy muab ntau yam khoom siv silicon carbide raws li cov kev xav tau tshwj xeeb ntawm semiconductor thiab photovoltaic industries.

Khoom Customization thiab Technical Support

Raws li lub tuam txhab ua lag luam ntawm silicon carbide thiab graphite cov khoom, VET Energy muab cov kev daws teeb meem nrog ntau yam txheej xws li SiC, TaC, glassy carbon, thiab pyrolytic carbon. Peb pab neeg muaj kev paub dhau los tuaj yeem muab cov kws tshaj lij kev taw qhia thiab kev txhawb nqa rau koj daim ntawv thov tshwj xeeb.

Ningbo VET Energy Technology Co., Ltd yog lub tuam txhab high-tech tsom mus rau kev txhim kho thiab tsim cov khoom siv high-end, cov ntaub ntawv thiab thev naus laus zis suav nrog graphite, silicon carbide, ceramics, kev kho saum npoo zoo li SiC txheej, TaC txheej, iav carbon txheej, pyrolytic carbon txheej, thiab lwm yam., cov khoom no tau siv dav hauv photovoltaic, zog, semiconductor, metallurgy, tshiab.

Peb pab pawg kws tshaj lij los ntawm cov tsev kawm tshawb fawb sab saum toj hauv tebchaws, thiab tau tsim ntau yam patented technologies los xyuas kom meej cov khoom ua tau zoo thiab zoo, kuj tuaj yeem muab cov neeg siv khoom nrog cov khoom siv kev daws teeb meem.