Cov khoom ntawm recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) yog cov khoom siv ua haujlwm siab nrog hardness thib ob rau pob zeb diamond, uas yog tsim los ntawm qhov kub siab tshaj 2000 ℃. Nws khaws ntau yam khoom zoo ntawm SiC, xws li kub siab zog, muaj zog corrosion kuj, zoo heev oxidation kuj, zoo thermal shock kuj thiab lwm yam.

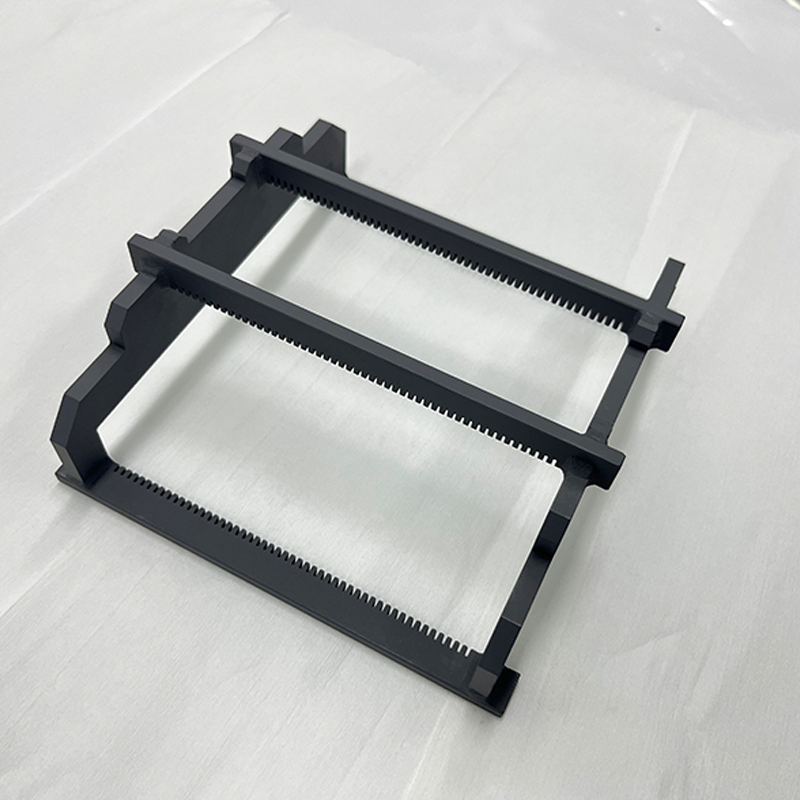

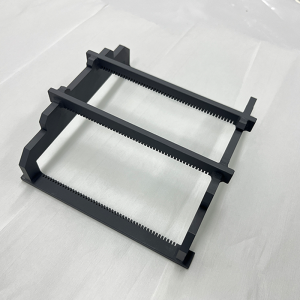

● Cov khoom siv kho tshuab zoo heev. Recrystallized silicon carbide muaj lub zog ntau dua thiab nruj dua li cov pa roj carbon fiber ntau, muaj kev cuam tshuam siab, tuaj yeem ua haujlwm zoo hauv qhov kub thiab txias, tuaj yeem ua si qhov kev ua tau zoo dua hauv ntau qhov xwm txheej. Tsis tas li ntawd, nws kuj muaj qhov hloov tau zoo thiab tsis yooj yim puas los ntawm kev ncab thiab khoov, uas ua rau nws ua tau zoo heev.

● High corrosion kuj. Recrystallized silicon carbide muaj kev tiv thaiv corrosion siab rau ntau yam xov xwm, tuaj yeem tiv thaiv kev yaig ntawm ntau yam corrosive media, tuaj yeem tswj nws cov khoom siv rau lub sijhawm ntev, muaj zog adhesion, kom nws muaj lub neej ntev kev pab cuam. Tsis tas li ntawd, nws kuj muaj qhov zoo thermal stability, tuaj yeem hloov kho rau qee qhov kev hloov pauv ntawm qhov kub thiab txias, txhim kho nws daim ntawv thov.

● Sintering tsis ntsws. Vim tias cov txheej txheem sintering tsis ntsws, tsis muaj kev ntxhov siab seem yuav ua rau deformation lossis tawg ntawm cov khoom, thiab cov khoom nrog cov duab nyuaj thiab siab precision tuaj yeem npaj tau.

| 重结晶碳化硅物理特性 Lub cev muaj zog ntawm Recrystalized Silicon Carbide | |

| 性质 / Khoom | 典型数值 / Tus nqi |

| 使用温度/ Ua haujlwm kub (°C) | 1600 ° C (nrog oxygen), 1700 ° C (txo ib puag ncig) |

| SiC含量/ SiC cov ntsiab lus | > 99.96% |

| 自由Si 含量/ Dawb Si cov ntsiab lus | <0.1% |

| 体积密度/Qhov ntom ntom | 2.60-2.70 g / cm33 |

| 气孔率/ Pom porosity | <16% |

| 抗压强度/ Compression zog | > 600MPa |

| 常温抗弯强度/Txias dabtsi yog khoov zog | 80-90 MPa (20 ° C) |

| 高温抗弯强度Kub dabtsi yog khoov zog | 90-100 MPa (1400 ° C) |

| 热膨胀系数/ Thermal expansion @ 1500 ° C | 4.70 10-6/°C |

| 导热系数/Thermal conductivity @ 1200 ° C | 23W/m•K |

| 杨氏模量/ Elastic modulus | 240 GPa |

| 抗热震性/ Thermal shock tsis kam | Zoo heev |

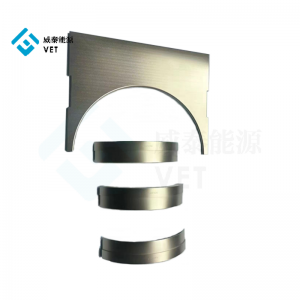

VET Energy yog lub chaw tsim khoom tiag tiag ntawm cov khoom siv graphite thiab silicon carbide nrog CVD txheej, tuaj yeem muab ntau yam khoom siv rau kev lag luam semiconductor thiab photovoltaic. Peb pab neeg ua haujlwm los ntawm cov tsev kawm tshawb fawb saum toj kawg nkaus hauv tebchaws, tuaj yeem muab cov ntaub ntawv tshaj lij tshaj lij rau koj.

Peb tsis tu ncua tsim cov txheej txheem siab heev los muab cov ntaub ntawv zoo tshaj plaws, thiab tau ua haujlwm tawm cov cuab yeej tshwj xeeb patented, uas tuaj yeem ua rau kev sib txuas ntawm cov txheej thiab cov substrate nruj dua thiab tsis tshua muaj detachment.

Zoo siab txais tos koj tuaj xyuas peb lub Hoobkas, cia peb tham ntxiv!