VET Energy Graphite Substrate Wafer Holder yog cov neeg nqa khoom zoo tsim los rau PECVD (Plasma Enhanced Chemical Vapor Deposition) txheej txheem. Qhov zoo tshaj plaws Graphite Substrate Holder yog ua los ntawm high-purity, high-density graphite khoom, nrog zoo heev kub kuj, corrosion kuj, seem stability thiab lwm yam ntxwv. Nws tuaj yeem muab qhov kev txhawb nqa ruaj khov rau cov txheej txheem PECVD thiab xyuas kom muaj kev sib haum xeeb thiab flatness ntawm zaj duab xis deposition.

VET Energy PECVD txheej txheem graphite wafer txhawb lub rooj muaj cov yam ntxwv hauv qab no:

▪High purity:tsis tshua muaj impurity cov ntsiab lus, tsis txhob kis cov yeeb yaj kiab, ua kom cov yeeb yaj kiab zoo.

▪High ceev:high density, siab mechanical zog, tuaj yeem tiv taus qhov kub thiab txias PECVD ib puag ncig.

▪Zoo dimensional stability:me me qhov hloov pauv ntawm qhov kub thiab txias, ua kom cov txheej txheem ruaj khov.

▪Zoo heev thermal conductivity:zoo hloov cua sov los tiv thaiv wafer overheating.

▪Muaj zog corrosion kuj:tuaj yeem tiv taus yaig los ntawm ntau yam corrosive gases thiab plasma.

▪Kev pabcuam customized:graphite txhawb cov ntxhuav ntawm ntau qhov sib txawv thiab cov duab tuaj yeem kho raws li cov neeg siv khoom xav tau.

Khoom zoo

▪Txhim kho zaj duab xis zoo:Ua kom cov yeeb yaj kiab tsis sib xws thiab txhim kho cov yeeb yaj kiab zoo.

▪Extend khoom lub neej:Zoo heev corrosion kuj, ncua lub neej kev pab cuam ntawm PECVD khoom.

▪Txo cov nqi tsim khoom:High-quality graphite tais tuaj yeem txo tus nqi seem thiab txo cov nqi tsim khoom.

Graphite khoom los ntawm SGL:

| Tus Qauv Zauv: R6510 | |||

| Index | Test txuj | Tus nqi | Chav tsev |

| Nruab nrab grain loj | ISO 13320 Kev Tswj Xyuas | 10 | ua m |

| Qhov ntom ntom | DIN IEC 60413 / 204 Kev Tswj Xyuas | 1.83 ib | g/cm3 |

| Qhib porosity | DIN66133 | 10 | % |

| Nruab nrab pore loj | DIN66133 | 1.8 | ua m |

| Permeability | TIAB SA 51935 | 0.06 ib | cm²/s |

| Rockwell hardness HR5/100 | IEC 60413 / 303 | 90 | HR |

| Tshwj xeeb hluav taws xob resistivity | DIN IEC 60413 / 402 Kev Tswj Xyuas | 13 | μΩm |

| Flexural zog | DIN IEC 60413 / 501 Kev Tswj Xyuas | 60 | MPa |

| Compressive zog | TIAB SA 51910 | 130 | MPa |

| Young's modulus | TIAB SA 51915 | 11.5 × 10 hli | MPa |

| Thermal expansion (20-200 ℃) | TIAB SA 51909 | 4.2 X 10-6 | K-1 |

| Thermal conductivity (20 ℃) | TIAB SA 51908 | 105 | Wm-1K-1 |

Nws yog tsim tshwj xeeb rau kev ua haujlwm siab hnub ci cell tsim, txhawb G12 loj-loj wafer ua. Optimized carrier tsim ho nce throughput, enabling ntau yield tus nqi thiab txo nqi ntau lawm.

| Yam khoom | Hom | Number wafer cab kuj |

| PEVCD Grephite nkoj - Lub 156 series | 156-13 grephite nkoj | 144 |

| 156-19 grephite nkoj | 216 | |

| 156-21 grephite nkoj | 240 | |

| 156-23 graphite nkoj | 308 | |

| PEVCD Grephite nkoj - Lub 125 series | 125-15 grephite nkoj | 196 |

| 125-19 grephite nkoj | 252 | |

| 125-21 grphite nkoj | 280 |

-

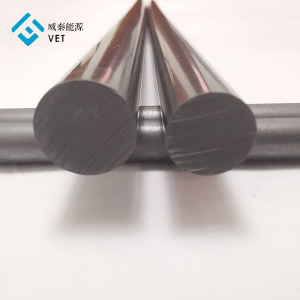

Txhawb kev cai graphite pas nrig kub kub lu ...

-

Kub teb system ntawm ib leeg siv lead ua kos rauv rauv

-

Graphite crucible rau ib qho kev loj hlob siv lead ua

-

Carbon Electrode Qws Graphite Qws Kev muag khoom

-

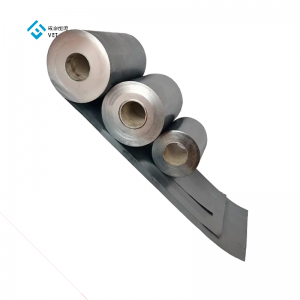

Graphite ntawv rau roj hlwb yog resistant rau h...

-

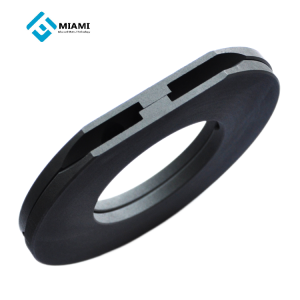

Ib nrab Bearing Bush Custom Carbon Tes Tsho Resin Ch...