Our kev vam meej nyob ib ncig ntawm lub tshuab tshiab, cov txuj ci zoo thiab muaj zog thev naus laus zis tsis tu ncua rau Kev Sib Tw Nqe rau Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Cov Hluav Taws Xob Cov Hluav Taws Xob Hluav Taws Xob Soft Graphite Felt, Honesty yog peb txoj cai, kev ua haujlwm tshaj lij yog peb ua, kev txhawb nqa yog peb lub hom phiaj, thiab cov neeg siv khoom ua tiav yog peb lub neej yav tom ntej!

Peb txoj kev vam meej nyob ntawm ib puag ncig cov tshuab tshiab, cov txuj ci zoo thiab cov cuab yeej siv dag zog tsis tu ncua rauTuam Tshoj Graphite Felt thiab Rigid Felt, Peb yuav ua peb qhov zoo tshaj plaws los koom tes & txaus siab rau koj vam khom rau qib siab zoo thiab tus nqi sib tw thiab zoo tshaj plaws tom qab kev pabcuam, ua tsaug tos ntsoov rau kev koom tes nrog koj thiab ua tiav yav tom ntej!

Cov pa roj carbon monoxide:

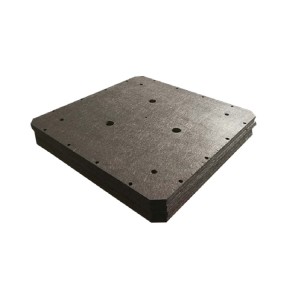

Carbon carbon composites (Carbon-fiber-reinforced carbon composites) (CFC) yog ib yam khoom tsim los ntawm lub zog siab carbon fiber thiab carbon matrix tom qab graphitization li kev ua.

Nws tuaj yeem siv dav hauv qhov kub thiab txias ib puag ncig ntawm ntau yam qauv, lub rhaub thiab lub nkoj. Piv nrog rau cov khoom siv engineering tsoos, carbon carbon composite muaj cov hauv qab no zoo:

1) Lub zog muaj zog

2) Kub kub txog 2000 ℃

3) Thermal shock tsis kam

4) Tsawg coefficient ntawm thermal expansion

5) Me me thermal muaj peev xwm

6) Zoo heev corrosion kuj thiab hluav taws xob tsis kam

Daim ntawv thov:

1. Aerospace. Vim tias cov khoom sib xyaw muaj qhov zoo thermal stability, siab tshwj xeeb lub zog thiab nruj. Nws tuaj yeem siv rau kev tsim cov dav hlau brakes, tis thiab lub fuselage, satellite kav hlau txais xov thiab cov qauv kev txhawb nqa, hnub ci tis thiab plhaub, cov cab kuj loj foob pob ua ntxaij plhaub, lub plhaub cav, thiab lwm yam.

2. Kev lag luam tsheb.

3. Kev kho mob.

4. Thaum tshav kub kub rwb thaiv tsev

5. Chav ntsuas kub

6. Cov hluav taws xob rwb thaiv tsev

| Cov ntaub ntawv qhia txog Carbon / Carbon Composite | |||

| Index | Chav tsev | Tus nqi | |

| Qhov ntom ntom | g/cm3 | 1.40-1.50 Nws | |

| Cov ntsiab lus carbon | % | ≥98.5 ~ 99.9 | |

| Tshauv | PPM | ≤65 | |

| Thermal conductivity (1150 ℃) | W/mk | 10-30 Nws | |

| Tensile zog | Mpa | 90-130 Nws | |

| Flexural zog | Mpa | 100-150 | |

| Compressive zog | Mpa | 130-170 Nws | |

| Shear zog | Mpa | 50 ~ 60 | |

| Interlaminar Shear zog | Mpa | ≥13 | |

| Hluav taws xob resistivity | Ω.mm2/m | 30-43 : kuv | |

| Coefficient ntawm Thermal Expansion | 106/K | 0.3 ~ 1.2 hli | |

| Ua Haujlwm Kub | ℃ | ≥2400 ℃ | |

| Tub rog zoo, tag nrho cov tshuaj vapor deposition rauv deposition, imported Toray carbon fiber T700 pre-woven 3D koob knitting Cov khoom siv tshwj xeeb: siab tshaj plaws sab nraud 2000mm, phab ntsa thickness 8-25mm, qhov siab 1600mm | |||

-

5kW vanadium ntws roj teeb, vanadium roj teeb, liab ...

-

30W hydrogen roj cell hluav taws xob generator, PEM F ...

-

2kW pem roj cell hydrogen generator, tshiab zog ...

-

330W hydrogen roj cell electric generator, elec ...

-

3kW hydrogen roj cell, roj cell pawg

-

5kW PEM roj cell, hluav taws xob tsheb hydrogen zog g ...

-

10kW vanadium redox flow roj teeb, lub zog cia ...

-

60W Hydrogen roj cell, Roj cell pawg, Proton ...

-

6KW Hydrogen Roj Cell Stack, Hydrogen Generator ...

-

Activated Carbon Fiber Npuag, activated carbon ...

-

Activated carbon fiber xav acf rau pov tseg ...

-

Aero Graphite Pwm Rau Photovoltaic

-

Cov pa roj carbon activated, activated carbon muaj...

-

Anode graphite phaj rau Hydrogen Roj generator

-

Anti-Oxidant Graphite Rotor thiab Ncej rau Alumi...