The Quartz Furnace Tubes are core consumables in semiconductor manufacturing, photovoltaic industry, material heat treatment and laboratory research. They are made of high purity fused silica (SiO2) with excellent thermal stability, chemical inertness and optical transparency. This product is designed for high temperature processes (such as diffusion, oxidation, CVD, annealing, etc.), and can be adapted to a variety of tube furnaces and PECVD equipment, which are widely used in wafer processing, photovoltaic cell coating, LED epitaxial growth and other high-precision fields.

The core advantages of VET Energy quartz tubes:

-Ultra-high purity material

Adopting 99.99% or more high-purity quartz sand, impurity content (Na, K, Fe, etc.) <10ppm, to avoid contamination of sensitive process environment.

Surface finish Ra≤0.8μm, reducing particle adhesion and guaranteeing coating uniformity.

-Excellent temperature resistance

Long-term working temperature: 1200℃ (continuous use); short-term temperature peak: 1450℃ (≤2 hours).

Low thermal expansion coefficient (5.5x10-7/℃), excellent thermal shock resistance, can withstand rapid temperature rise and fall (≤10℃/min).

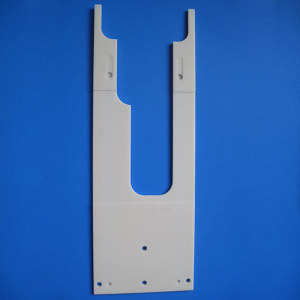

-Precise size control

Tolerance of inner diameter ±0.5mm, straightness error <1mm/m, to ensure a close match with the furnace body.

Support non-standard customization, inner diameter range 20mm-500mm, length 100mm-3000mm.

-Chemical inertness and corrosion resistance

Resistant to strong acid (except HF), strong alkali and most organic solvents, prolonging service life.

Excellent gas tightness, leakage rate <<1x10-9 Pa.m3/s, suitable for vacuum or protective gas environment.

-Customized service

Support openings, flanges, multi-channels, shaped structures and other designs to meet special process requirements.

Can be pre-plated with silicon carbide (SiC) coating to enhance crystallization resistance.

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.