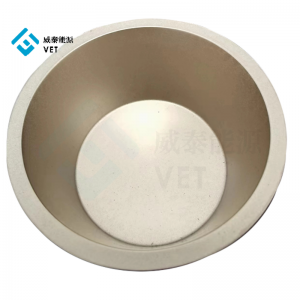

Glass carbon crucible is a kind of crucible made of special materials for high temperature experiments and applications. It has excellent high temperature resistance, good chemical stability and high purity, so it is widely used in various fields, such as metallurgy, ceramics, chemicals, semiconductors and so on.

The manufacturing process of glass carbon crucible is very complex, which needs to go through multiple processes and strict quality control. First of all, it is necessary to use high-purity raw materials, such as graphite, asphalt, etc., after high temperature treatment and chemical reaction, to make glass carbon powder. Then, the powder is formed into the shape of the crucible after forming, sintering and other processes. Finally, it is also necessary to carry out high-temperature annealing, grinding, polishing and other treatments to ensure the quality and performance of the crucible.

Peculiarity:

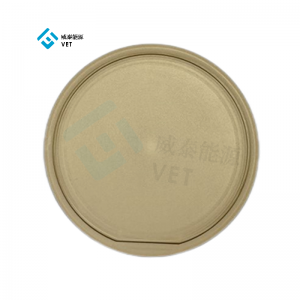

Various graphite materials can be used as substrates

The properties of the graphite substrate are not lost

It can reduce the formation of graphite dust

Has better scratch resistance and other anti-friction durability

Apply:

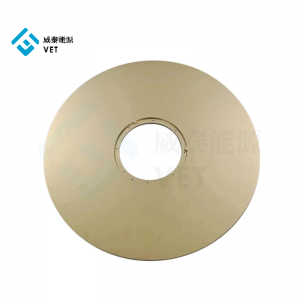

Monocrystalline silicon drawing equipment components

Epitaxial growing parts

Continuous casting die

Glass seal fixture

|

Material |

Bulk density |

Hardness |

Electrical resistivity |

Bending strength |

Compressive strength |

|

ISEM-3 |

0 |

0 |

0 |

0 |

0 |

|

GP1B |

0 |

+3% |

0 |

+8% |

+3% |

|

GP2Z |

0 |

+3% |

- |

+7% |

+4% |

|

GP2B |

0 |

+3% |

0 |

+13% |

+3% |