High Quality for Electric Brake Vacuum Pump In Rotary Vane - CVD furnace for SiC coating – VET Energy Detail:

CVD furnace (SiC、BN)

Furnace used for anti-oxidation coating, matrix material character change and etc. by using Silicohydride gas source. It has both horizontal and vertical structures.

Application: SiC coating for C/C composite material, SiC coating for graphite, SiC, BN and ZrC coating for fiber and etc.

Specification

v:* {behavior:url(#default#VML);}

o:* {behavior:url(#default#VML);}

x:* {behavior:url(#default#VML);}

.shape {behavior:url(#default#VML);}

| Model | Working Zone Size(W × H × L) (mm) | Max. Temperature (°C) | Temperature Uniformity (°C) | Ultimate Vacuum (Pa) | Pressure Increase Rate (Pa/h) |

| Horizontal structure | |||||

| LFH-6900-SiC | 600 × 600 × 900 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFH-10015-SiC | 1000 × 1000 × 1500 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFH-1220-SiC | 1200×1200×2000 | 1500 | ±10 | 1-100 | 0.67 |

| LFH-1530-SiC | 1500×1500×3000 | 1500 | ±10 | 1-100 | 0.67 |

| LFH-2535-SiC | 2500×2000×3500 | 1500 | ±10 | 1-100 | 0.67 |

| Vertical structure | |||||

| LFV-D3050-SiC | φ300×500 | 1500 | ±5 | 1-100 | 0.67 |

| LFV-D6080-SiC | φ600×800 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFV-D8120-SiC | φ800×1200 | 1500 | ±7.5 | 1-100 | 0.67 |

| LFV-D11-SiC | φ1100×2000 | 1500 | ±10 | 1-100 | 0.67 |

| LFV-D26-SiC | φ2600×3200 | 1500 | ±10 | 1-100 | 0.67 |

Technical Features

1. Using the most advanced control technology, it can precise control the MTS flow and pressure, the deposition flow is stable and pressure fluctuate in narrow range;

2. Special designed deposition chamber with good sealing effect and great anti-contamination performance;

3. Using multiple deposition channels with uniformity gas flow, without deposition dead corner and perfect deposition surface;

4. It has treatment for the high corrosive gas, flammable and explosive gas , solid dust and low melting point sticky materials during the deposition process;

5. Using newly designed corrosion resistant vacuum pump which has long continuous working hours and low maintenance rate.

Optional Configuration of CVD Furnace

1. Furnace door: screw/hydraulic/manual elevation type;swing opening/parallel opening(large size furnace door); manual tight/ auto lock-ring tight

2. Furnace vessel: all carbon steel/inner layer stainless steel/all stainless steel

3. Furnace hot zone: soft carbon felt/soft graphite felt/rigid composite felt/CFC

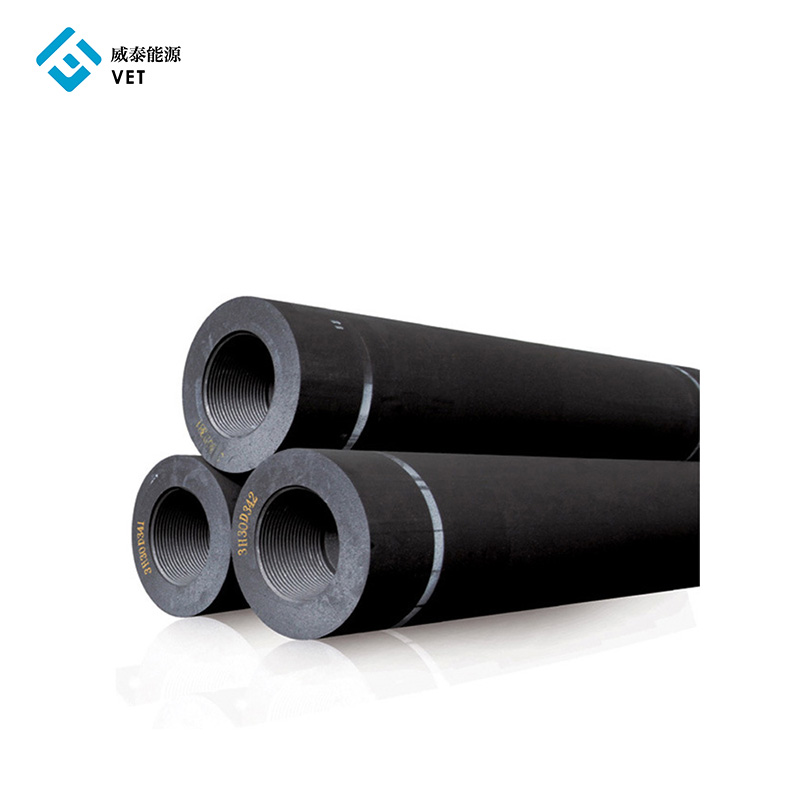

4. Heating element and muffle: isostatic press graphite/high purity, strength and density graphite/fine size graphite

5. Process gas system: volume/mass flow-meter

6.Thermocouple: K type/N type/C type/S type

Product detail pictures:

Related Product Guide:

Murray’s Cheese and Blue Apron Will Ship a Charcuterie Spread to Your Door | Fire Water Cannon

#LetsChalkShabbat: Spiritual Messages in Concrete Jungles – How a group of women are using urban sidewalk art to broadcast Shabbat awareness | Type Butterfly Valve

High Quality for Electric Brake Vacuum Pump In Rotary Vane - CVD furnace for SiC coating – VET Energy, The product will supply to all over the world, such as: , , ,

-

OEM/ODM China 700mm Uhp Graphite Electrode - G...

-

Low price for Vacuum Pump Graphite Rotor Vane -...

-

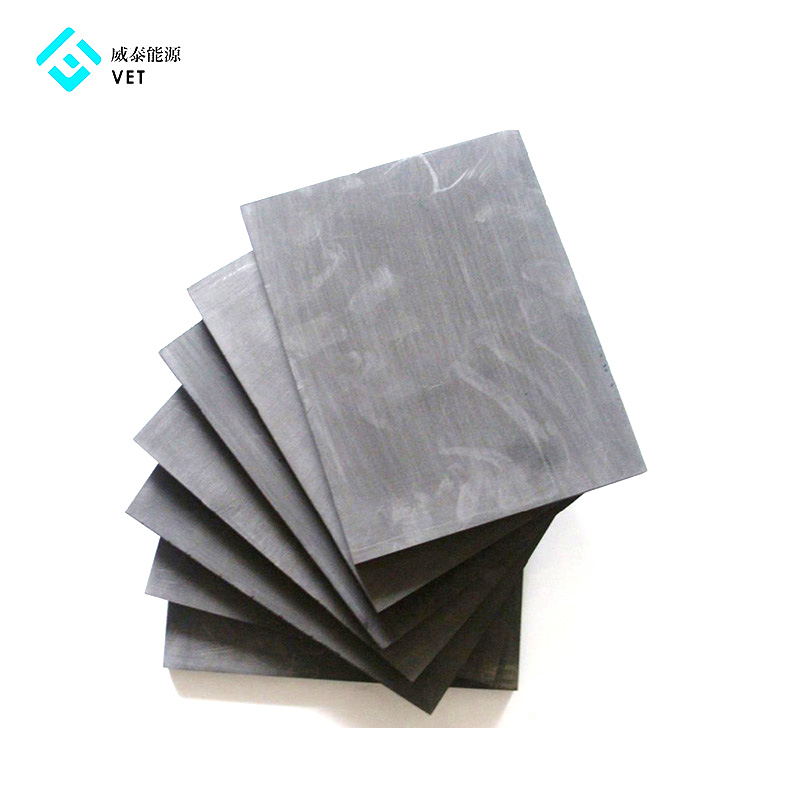

Short Lead Time for Price For Graphite Plate -...

-

China wholesale Graphite Plate - High density ...

-

Best quality Graphite Boat - 100% Original Non...

-

High definition Silicon Carbide Coating - Fact...