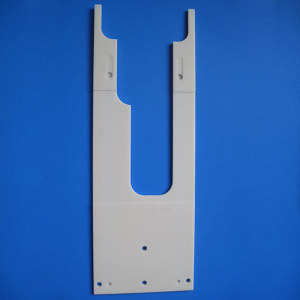

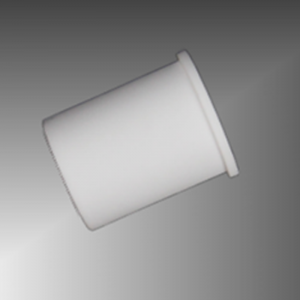

Quartz Wafer Boat is a key carrier tool in semiconductor manufacturing, photovoltaic cell production and advanced material research and development, designed for stable wafer transfer and positioning in high-temperature processes. This product is made of ultra-high purity fused silica (SiO2), with excellent temperature resistance, chemical stability and ultra-low metal contamination characteristics, suitable for diffusion furnace, oxidation furnace, PECVD/LPCVD and other equipment, widely used in wafer coating, ion implantation, high temperature annealing and other core processe.

The Core Advantages of VET Energy’s quartz boat:

- Ultra-high purity material

Purity ≥99.99%: Impurity content (Na, K, Fe, etc.) <5ppm, avoiding wafer contamination and guaranteeing chip yield.

Low precipitation and adsorption: the surface is super-polished (Ra≤0.4μm) to reduce particle adhesion and gas residue. - High temperature stability

Temperature limit: Long-term working temperature of 1100℃, short-term peak of 1300℃, no deformation, no crystal precipitation.

Low thermal expansion coefficient (5.5x10-7/℃), excellent thermal shock resistance, adaptable to rapid temperature rise and fall process (e.g. RTP rapid annealing). - Precise structural design

Slot precision±0.1mm: matching 2”to 12” wafers, spacing uniformity error <0.05mm, ensuring wafers have no offset.

High load capacity: Maximum load of 50 wafers (in terms of 12” wafers) in a single boat, supporting stable transfer of thin wafers (≥100um). - Chemical inertness

Corrosion resistance: Resistant to acid (except HF), alkali and organic solvent corrosion, compatible with CMP cleaning process.

Excellent gas tightness: Leakage rate <5x10-10 Pa.m3/s, suitable for vacuum and protective gas environments. - Long life and maintainability

Life expectancy ≥ 5000 cycles (normal working conditions), the surface can be repeatedly cleaned and used, reducing the overall cost.

Modular design: supports partial replacement (e.g. single boat tooth), reducing downtime.

We offer both transparent and frosted surfaces according to customer’s requirements:

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the production and sales of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc..

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.