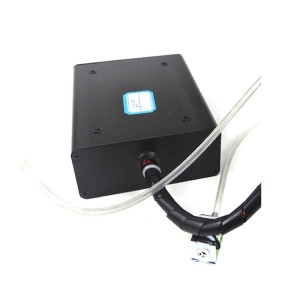

vet-china ta gabatar da wani sabon jirgin ruwan Wafer na zamani wanda aka ƙera don ƙarni na gaba na masana'antar semiconductor. Wannan kwale-kwalen da aka ƙera da kyau yana ba da daidaito mara misaltuwa a cikin sarrafa wafer, yana tabbatar da aiki mara kyau da rage haɗarin lalacewa yayin sarrafawa.

Gina tare da ingantattun kayan aiki, Boat ɗin Wafer na Contiguous yana alfahari da ingantaccen yanayin zafi da juriya na musamman, yana mai da shi manufa don yanayin zafi mai zafi da matsanancin yanayin sinadarai. Ƙirƙirar ƙirar sa yana tabbatar da cewa ana riƙe wafers cikin aminci kuma suna daidaita daidai, yana inganta kayan aiki da haɓaka haɓakar masana'antu.

Wannan jirgin ruwan wafer na yankan-baki an ƙera shi don biyan buƙatun buƙatun na zamani na zamani, yana tallafawa nau'ikan wafer iri-iri da daidaitawa. Ta hanyar haɗa Boat ɗin Wafer mai ci gaba daga vet-china cikin layin samarwa ku, zaku iya tsammanin ingantaccen aiki, rage raguwar lokaci, da haɓaka yawan amfanin ƙasa.

Gane bambanci tare da sadaukarwar vet-china ga inganci da ƙirƙira, isar da samfuran da ke tura iyakokin masana'antar semiconductor. Zaɓi Boat ɗin Wafer mai ci gaba kuma ku haɓaka ƙarfin sarrafa wafer ɗinku zuwa sabon tsayi.

Abubuwan da aka sake yi na silicon carbide

Silicone carbide Recrystallized (R-SiC) abu ne mai girman gaske tare da taurin na biyu kawai zuwa lu'u-lu'u, wanda aka kafa a babban zafin jiki sama da 2000 ℃. Yana riƙe da kyawawan kaddarorin SiC masu yawa, kamar ƙarfin zafin jiki mai ƙarfi, juriya mai ƙarfi mai ƙarfi, juriya mai kyau na iskar shaka, juriya mai ƙarfi na thermal da sauransu.

● Kyakkyawan kayan aikin injiniya. Silikon carbide da aka sake yin amfani da shi yana da ƙarfin ƙarfi da taurin kai fiye da fiber carbon, juriya mai ƙarfi, yana iya yin aiki mai kyau a cikin matsanancin yanayin zafin jiki, yana iya yin kyakkyawan aiki mai daidaitawa a cikin yanayi daban-daban. Bugu da ƙari, yana da kyakkyawan sassauci kuma ba a sauƙi lalacewa ta hanyar mikewa da lanƙwasa, wanda ke inganta aikinsa sosai.

● Babban juriya na lalata. Silikon carbide da aka sake yin amfani da shi yana da juriya mai ƙarfi ga kafofin watsa labaru iri-iri, yana iya hana yazawar kafofin watsa labaru iri-iri, yana iya kiyaye kaddarorin injinsa na dogon lokaci, yana da mannewa mai ƙarfi, don ya sami tsawon rayuwar sabis. Bugu da ƙari, yana da kwanciyar hankali mai kyau na thermal, zai iya daidaitawa zuwa wani nau'i na canje-canje na zafin jiki, inganta tasirin aikace-aikacensa.

● Yin zuzzurfan tunani ba ya raguwa. Saboda tsarin sintering ba ya raguwa, babu sauran damuwa da zai haifar da lalacewa ko fashe samfurin, kuma ana iya shirya sassan da ke da sifofi masu rikitarwa da madaidaici.

| 重结晶碳化硅物理特性 Kaddarorin jiki na Silicon Carbide Recrystallized | |

| 性质 / Dukiya | 典型数值 / Yawan Daraja |

| 使用温度/ Yanayin aiki (°C) | 1600°C (tare da oxygen), 1700°C (rage yanayi) |

| SiC含量/ SiC abun ciki | > 99.96% |

| 自由Si含量/ Free Si abun ciki | <0.1% |

| 体积密度/Yawan yawa | 2.60-2.70 g/cm3 |

| 气孔率/ Bayyanar porosity | <16% |

| 抗压强度/ Ƙarfin matsawa | > 600MPa |

| 常温抗弯强度/Ƙarfin lanƙwasa sanyi | 80-90 MPa (20°C) |

| 高温抗弯强度Ƙarfin lanƙwasawa mai zafi | 90-100 MPa (1400°C) |

| 热膨胀系数/ Thermal Fadada @1500°C | 4.70 10-6/°C |

| 导热系数/Ƙarfin zafin jiki @1200°C | 23W/m•K |

| 杨氏模量/ Na roba modules | 240 GPA |

| 抗热震性/ thermal girgiza juriya | Madalla da kyau |

Kudin hannun jari VET Energy daainihin manufacturer na musamman graphite da silicon carbide kayayyakin tare da CVD shafi,iya bayarwadaban-dabansassa na musamman don semiconductor da masana'antar hotovoltaic. OƘungiyar fasaha ta ur ta fito ne daga manyan cibiyoyin bincike na gida, za su iya samar da ƙarin ƙwararrun kayan aikina ka.

Muna ci gaba da haɓaka matakai na ci gaba don samar da ƙarin kayan haɓaka,kumasun yi aiki da keɓantaccen fasaha mai ƙima, wanda zai iya sa haɗin kai tsakanin sutura da abin da ke ƙasa ya fi ƙarfi kuma ƙasa da ƙasa don cirewa.

| CVD SiC薄膜基本物理性能 Asalin kaddarorin jiki na CVD SiCshafi | |

| 性质 / Dukiya | 典型数值 / Yawan Daraja |

| 晶体结构 / Tsarin Crystal | FCC β lokaci多晶,主要为(111) 取向 |

| 密度 / Yawan yawa | 3.21g/cm³ |

| 硬度 / Tauri | 2500 维氏硬度 (500g kaya) |

| 晶粒大小 / Hatsi SiZe | 2 ~ 10 μm |

| 纯度 / Sinadaran Tsabta | 99.99995% |

| 热容 / Ƙarfin zafi | 640kg-1· K-1 |

| 升华温度 / Sublimation Zazzabi | 2700 ℃ |

| 抗弯强度 / Ƙarfin Ƙarfi | 415 MPa RT 4-point |

| 杨氏模量 / Matasa Modul | 430 Gpa 4pt lankwasa, 1300 ℃ |

| 导热系数 / ThermalGudanarwa | 300 w·m-1· K-1 |

| 热膨胀系数 / Fadada thermal (CTE) | 4.5×10-6K-1 |

Barka da zuwa ziyarci masana'antar mu, bari mu kara tattaunawa!