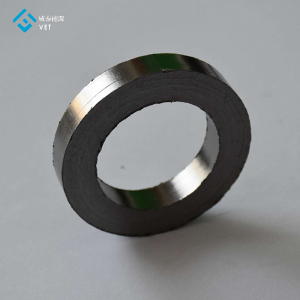

VET Energy Graphite Substrate Wafer Holder is a precision carrier designed for PECVD (Plasma Enhanced Chemical Vapor Deposition) process. This high-quality Graphite Substrate Holder is made of high-purity, high-density graphite material, with excellent high temperature resistance, corrosion resistance, dimensional stability and other characteristics. It can provide a stable support platform for PECVD process and ensure the uniformity and flatness of film deposition.

VET Energy PECVD process graphite wafer support table has the following characteristics:

▪ High purity: extremely low impurity content, avoid contamination of film, ensure film quality.

▪ High density: high density, high mechanical strength, can withstand high temperature and high pressure PECVD environment.

▪ Good dimensional stability: small dimensional change at high temperature, ensuring process stability.

▪ Excellent thermal conductivity: effectively transfer heat to prevent wafer overheating.

▪ Strong corrosion resistance: can resist erosion by various corrosive gases and plasma.

▪ Customized service: graphite support tables of different sizes and shapes can be customized according to customer needs.

Product Advantages

▪ Improve film quality: Ensure uniform film deposition and improve film quality.

▪ Extend equipment life: Excellent corrosion resistance, extend the service life of PECVD equipment.

▪ Reduce production costs: High-quality graphite trays can reduce scrap rate and reduce production costs.

Graphite material from SGL:

|

Typical parameter: R6510 |

|||

| Index | Test standard | Value | Unit |

| Average grain size | ISO 13320 | 10 | μm |

| Bulk density | DIN IEC 60413/204 | 1.83 | g/cm3 |

| Open porosity | DIN66133 | 10 | % |

| Medium pore size | DIN66133 | 1.8 | μm |

| Permeability | DIN 51935 | 0.06 | cm²/s |

| Rockwell hardness HR5/100 | DIN IEC60413/303 | 90 | HR |

| Specific electrical resistivity | DIN IEC 60413/402 | 13 | μΩm |

| Flexural strength | DIN IEC 60413/501 | 60 | MPa |

| Compressive strength | DIN 51910 | 130 | MPa |

| Young's modulus | DIN 51915 | 11.5×10³ | MPa |

| Thermal expansion(20-200℃) | DIN 51909 | 4.2X10-6 | K-1 |

| Thermal conductivity (20℃) | DIN 51908 | 105 | Wm-1K-1 |

It is specifically designed for high-efficiency solar cell manufacturing, supporting G12 large-size wafer processing. Optimized carrier design significantly increases throughput, enabling higher yield rates and lower production costs.

| Item | Type | Number wafer carrier |

| PEVCD Grephite boat - The 156 series | 156-13 grephite boat | 144 |

| 156-19 grephite boat | 216 | |

| 156-21 grephite boat | 240 | |

| 156-23 graphite boat | 308 | |

| PEVCD Grephite boat - The 125 series | 125-15 grephite boat | 196 |

| 125-19 grephite boat | 252 | |

| 125-21 grphite boat | 280 |