Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for Good quality Silicon Carbide RBSIC/SISIC Cantilever Paddle Used in Solar Photovoltaic Industry, We sincerely welcome the two foreign and domestic business enterprise companions, and hope to operate with you in the close to long term!

Well-run tools, expert profits crew, and much better after-sales products and services; We’ve been also a unified major spouse and children, every person stick to the company benefit “unification, dedication, tolerance” for China Refractory ceramic and ceramic kiln, To meet the requirements of particular person customers for each bit more perfect service and stable quality items. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

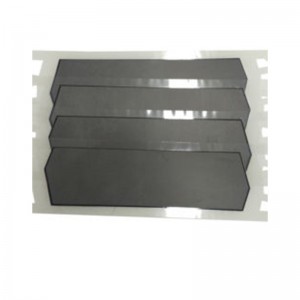

SiC coating/coated of Graphite substrate for Semiconductor Susceptors hold and heat semiconductor wafers during thermal processing. A susceptor is made of a material which absorbs energy by induction, conduction, and/or radiation and heats the wafer. Its thermal shock resistance, thermal conductivity, and purity are critical to rapid thermal processing (RTP). Silicon carbide coated graphite, silicon carbide (SiC), and silicon (Si) are commonly used for susceptors depending on the specific thermal and chemical environment. PureSiC® CVD SiC and ClearCarbon™ ultra-pure material which delivers superior thermal stability, corrosion resistance, and durability. Product Description

SiC coating of Graphite substrate for Semiconductor applications produces a part with superior purity and resistance to oxidizing atmosphere.

CVD SiC or CVI SiC is applied to Graphite of simple or complex design parts. Coating can be applied in varying thicknesses and to very large parts.

Technical ceramics are a natural choice for semiconductor thermal processing applications including RTP (Rapid Thermal Processing), Epi (Epitaxial), diffusion, oxidation, and annealing. CoorsTek provides advanced material components specifically designed to withstand thermal shocks with high-purity, sturdy, repeatable performance for high-temperature

Features:

· Excellent Thermal Shock Resistance

· Excellent Physical Shock Resistance

· Excellent Chemical Resistance

· Super High Purity

· Availability in Complex Shape

· Usable under Oxidizing Atmosphere

application:

A wafer needs to pass through several steps before it is ready for use in electronic devices. One important process is silicon epitaxy, in which the wafers are carried on graphite susceptors. The properties and quality of the susceptors have a crucial effect on the quality of the wafer’s epitaxial layer.

Typical Properties of Base Graphite Material:

| Apparent Density: | 1.85 g/cm3 |

| Electrical Resistivity: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Shore Hardness: | 58 |

| Ash: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

More Produ

-

Factory wholesale Low Electeic Resistance Elect...

-

Chinese Professional China Graphite Crucible fo...

-

OEM/ODM Supplier Water-Cooled Membrane Electrod...

-

China Factory for Hot Sale High Quality Customi...

-

Hot sale Exchange Membrane Hydrogen Fuel Cell M...

-

Popular Design for China Supply High Quality Mo...