All we do is always related with our tenet ” Client first, Have confidence in 1st, devoting about the meals packaging and environmental protection for Factory Selling China Polished Silicon Carbide Sisic Grinding Barrel Shape Sic Tube for Grinding Mill, We warmly welcome prospects, organization associations and mates from everywhere in the earth to get in touch with us and request cooperation for mutual benefits.

All we do is always related with our tenet ” Client first, Have confidence in 1st, devoting about the meals packaging and environmental protection for China SAE1026 Honing Tube, S45c Honed Tube, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Product Description

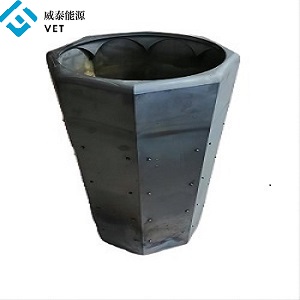

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer.

Main features:

1. High temperature oxidation resistance:

the oxidation resistance is still very good when the temperature is as high as 1600 C.

2. High purity : made by chemical vapor deposition under high temperature chlorination condition.

3. Erosion resistance: high hardness, compact surface, fine particles.

4. Corrosion resistance: acid, alkali, salt and organic reagents.

Main Specifications of CVD-SIC Coating

|

SiC-CVD Properties |

||

| Crystal Structure | FCC β phase | |

| Density | g/cm ³ | 3.21 |

| Hardness | Vickers hardness | 2500 |

| Grain Size | μm | 2~10 |

| Chemical Purity | % | 99.99995 |

| Heat Capacity | J·kg-1 ·K-1 | 640 |

| Sublimation Temperature | ℃ | 2700 |

| Felexural Strength | MPa (RT 4-point) | 415 |

| Young’ s Modulus | Gpa (4pt bend, 1300℃) | 430 |

| Thermal Expansion (C.T.E) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |

-

Custom high temperature and corrosion resistant...

-

Cheap PriceList for Purity And Durability Isost...

-

Best Price on China Bimetal Bush for Concrete I...

-

Factory Price China High Pure Graphite Bipolar ...

-

China Cheap price China High Quality Graphite B...

-

2022 high quality MOCVD Susceptor Buy online in...