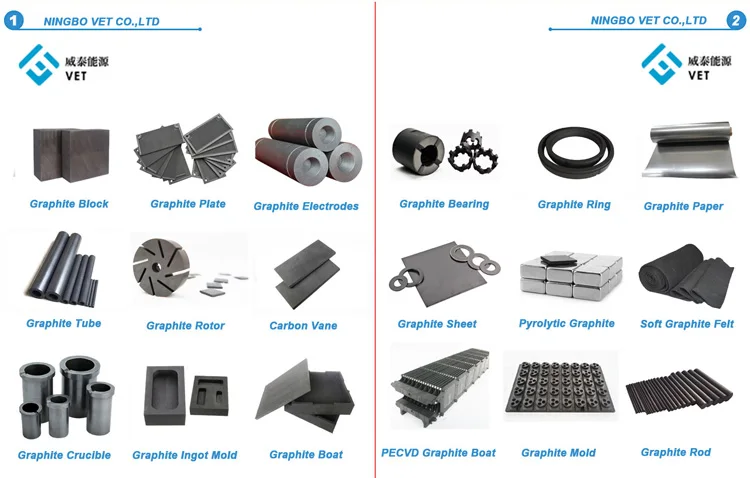

Features:

- Fine grain

- Homogeneous structure

- High density

- Excellent thermal conductivity

- High mechanical strength

- Proper electrical conductivity

- Minimum wettability to molten metals

Typical Sizes:

| Blocks | Length x Width x Thickness (mm) 200x200x70, 250x130x100, 300x150x100, 280x140x110, 400x120x120, 300x200x120, 780x210x120, 330x260x120, 650x200x135, 650x210x135, 380x290x140, 500x150x150, 350x300x150, 670x300x150, 400x170x160, 550x260x160, 490x300x180, 600x400x200, 400x400x400 |

| Rounds | Diameter (mm): 60, 100, 125, 135, 150, 200, 250, 300, 330, 400, 455 Thickness (mm): 100, 135, 180, 220, 250, 300, 450 |

* Other dimensions are available on request.

Specifications:

| Specifications | Unit | Value |

| Bulk Density | g/cc | 1.70 - 1.85 |

| Compressive Strength | MPa | 30 - 80 |

| Bending Strength | MPa | 15 – 40 |

| Shore hardness | 30 – 50 | |

| Specific Resistance | micro ohm.m | 8.0 – 15.0 |

| Ash (Normal Grade) | % | 0.05 – 0.2 |

| Ash (purified) | ppm | 30 – 50 |

Applications:

- Molds, chutes, sleeves, sheathes, linings, etc. in continuous casting systems for making shaped steel, cast iron, copper, aluminum.

- Sintering molds for cemented carbides and diamond tools.

- Sintering molds for electronic components.

- Electrodes for EDM.

- Heaters, heat shields, crucibles, boats in some industrial furnaces (such as furnaces for pulling monocrystalline silicon or optical fibers).

- Bearings and seals in pumps, turbines and motors.

- and so on.

-

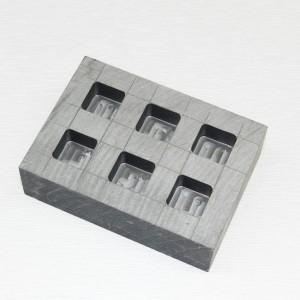

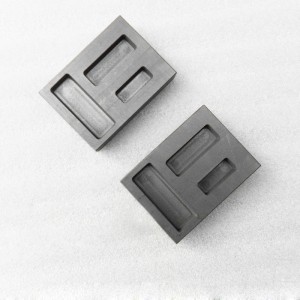

150g gold Graphite Ingot Mold

-

10oz gold casting Graphite Ingot Mold

-

0.5Lb Copper Graphite Ingot Mold

-

0.25oz silver Graphite Ingot Mold

-

1.75oz gold Graphite Ingot Mold

-

1kg gold Graphite Ingot Mold

-

1oz Gold Bar Graphite Ingot Mold

-

3Kg Gold Bar Graphite Ingot Mold

-

Activated Carbon Fiber Fabric, activated carbon...

-

Activated carbon fibre felt acf for disposable ...

-

Antimony Alloy Graphite Bushings/ Bearing

-

Bottom price China Manufacture of Carbon Graphi...

-

Carbon block best price for arc furnace