We believe in: Innovation is our soul and spirit. Good quality is our life. Shopper need to have is our God for Factory Outlets China First Hand Manufacture Activated Charcoal Fiber Activated Carbon Acf Felt, Our products and solutions are widely recognized and reliable by users and can meet continuously changing economic and social needs.

We believe in: Innovation is our soul and spirit. Good quality is our life. Shopper need to have is our God for China Air Purification, Filter, Our company covers an area of 20, 000 square meters. We have now more than 200 workers, qualified technical team, 15 years’ experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, make sure you do not hesitate to contact us.

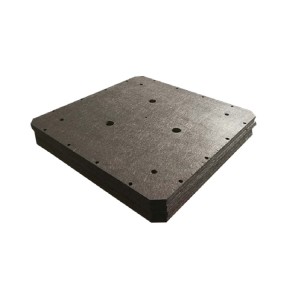

Carbon Carbon Composites:

Carbon carbon composites (Carbon-fiber-reinforced carbon composites) (CFC) is a kind of material formed by high strength carbon fiber and carbon matrix after graphitization enhancement processing.

It can be widely used in the high temperature environment of various structure, heater and vessel. Compared with the traditional engineering materials, carbon carbon composite has the following advantages:

1) High strength

2) High temperature up to 2000℃

3)Thermal shock resistance

4) Low coefficient of thermal expansion

5) Small thermal capacity

6) Excellent corrosion resistance and radiation resistance

Application:

1. Aerospace. Because of the composite material has good thermal stability, high specific strength and stiffness. It can be used for manufacturing of aircraft brakes, wing and fuselage, satellite antenna and a support structure, solar wing and shell, large carrier rocket shell, engine shell, etc..

2. The automobile industry.

3. The medical field.

4. Heat-insulation

5. Heating Unit

6. Ray-insulation

|

Technical Data of Carbon/Carbon Composite |

|||

| Index |

Unit |

Value |

|

| Bulk density |

g/cm3 |

1.40~1.50 |

|

| Carbon content |

% |

≥98.5~99.9 |

|

| Ash |

PPM |

≤65 |

|

| Thermal conductivity (1150℃) |

W/m.k |

10~30 |

|

| Tensile strength |

Mpa |

90~130 |

|

| Flexural Strength |

Mpa |

100~150 |

|

| Compressive strength |

Mpa |

130~170 |

|

| Shear strength |

Mpa |

50~60 |

|

| Interlaminar Shear strength |

Mpa |

≥13 |

|

| Electric resistivity |

Ω.mm2/m |

30~43 |

|

| Coefficient of Thermal Expansion |

106/K |

0.3~1.2 |

|

| Processing Temperature |

℃ |

≥2400℃ |

|

| Military quality, full chemical vapor deposition furnace deposition, imported Toray carbon fiber T700 pre-woven 3D needle knitting Material specifications: maximum outer diameter 2000mm, wall thickness 8-25mm, height 1600mm |

|||

-

5kW vanadium flow battery,vanadium battery ,red...

-

30W hydrogen fuel cell electric generator,PEM F...

-

2kW pem fuel cell hydrogen generator,new energy...

-

330W hydrogen fuel cell electric generator,elec...

-

3kW hydrogen fuel cell , fuel cell stack

-

5kW PEM fuel cell,electric car hydrogen power g...

-

10kW vanadium redox flow battery,energy storage...

-

60W Hydrogen fuel cell, Fuel cell stack, Proton...

-

6KW Hydrogen Fuel Cell Stack,hydrogen generator...

-

Activated Carbon Fiber Fabric, activated carbon...

-

Activated carbon fibre felt acf for disposable ...

-

Aero Graphite Mold For Photovoltaic

-

Active carbon felt, activated carbon felt fabri...

-

Anode graphite plate for Hydrogen Fuel generator

-

Anti-Oxidant Graphite Rotor and Shaft for Alumi...