We always believe that one’s character decides products’ quality, the details decides products’ quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Factory making Graphite Rotor/graphite Impeller, Our firm warmly welcome friends from everywhere in the globe to visit, examine and negotiate business enterprise.

We always believe that one’s character decides products’ quality, the details decides products’ quality ,with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

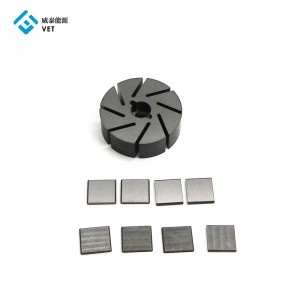

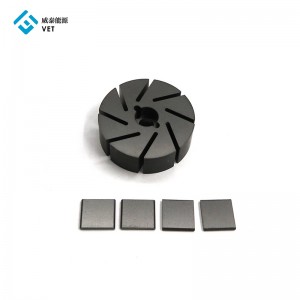

Graphite vane & rotor for Vacuum Pump & Fuel pump

Application

Vacuum Pumps

Chemical pumps

Gasoline vapor pick up pumps

Oil free air pumps

Fuel & fuel transfer pumps

Rotary Compressors for fresh air

Printing industry

Medical applications

Beverage pumps

Packaging machines

Material

1.Density:1.95-2.00g/cm3

2.Compressive strength:80Mpa

3.Ash content:0.20%

4.Dimension: As your drawing or sample or your given requirements.

Graphite Material with Resin, Antimony, Babbitt, Bronze, ect Impregnation are available. The best grade material will be recommended as customer’s actual applications.

Advantages

Self lubricating – dry running

Low wear rate

Low coefficient of thermal expansion

Dimensionally stable

Compatible with food & pharmaceuticals

Excellent thermal shock

Good hardness

Good impact resistance

Excellent strength

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

Factory wholesale China High Density Graphite C...

-

High Quality Manufacture of Lightweight Graphit...

-

Factory Cheap Hot China Twin Screw Dry Vacuum Pump

-

Rapid Delivery for China Graphite Block as Moul...

-

Reliable Supplier China High Temperature Resist...

-

Graphite Solid Self Lubricating Oil Bearing,gra...