We now have a highly efficient crew to deal with inquiries from clients. Our intention is “100% shopper pleasure by our merchandise quality, price tag & our staff service” and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Factory best selling China Four Parts Cast Iron Cube Moulds, We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

We now have a highly efficient crew to deal with inquiries from clients. Our intention is “100% shopper pleasure by our merchandise quality, price tag & our staff service” and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of China Concrete Testing Mould, Mould, Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

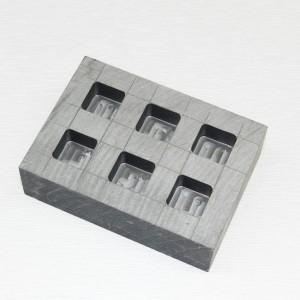

Graphite crystallizer refers to a graphite product used in a continuous casting mold. Metal continuous casting technology is a new technology for directly forming molten metal through a continuous casting mold. Because it is directly formed without rolling, it avoids secondary heating of the metal, so it can save a lot of energy. Compared with other graphite materials, continuous casting graphite is characterized by fine particles, uniform texture, large bulk density, low porosity and high strength.

Material

| Bulk density | 1.80g/cm3 |

| Shore hardness | 55 |

| CET | 4.8×10*6/C |

| Resistance | 11-13 unm |

| Flexural strength | 40 MPa |

| Compressive strength | 90MPa |

Application

Gold,silver,copper,precious metal casting

Useful Tips for using ingot molds:

1: Heat the graphite mold to 250c-500c to avoid any damages in the process and for a higher quality result.

Heating temperatures may vary for different materials.

2: Place scrap into graphite crucible, heat graphite crucible until metal reaches a liquefied state.

Pour molted metal into the pre-heated mold.

3: The graphite molds will last several pours depending on temperatures and types of metal that you are casing.

4: If you run into a releasing problem, you may freeze the mold to allow the ingot to release.

Note: these instructions can be used for all size graphite ingot molds.

These molds can be used for casting gold, silver, copper, platinum, aluminum, arsenic, iron, tin…

Warning: molds and metals will be extremely hot .proceed with caution.

Mobile/Wechat/Whatsapp: 86-189 1159 6362