We have developed cost- effective graphite bipolar plates which requires the use of advanced bipolar plates with high electrical conductivity and good mechanical strength. It is refined by high-pressure forming, vacuum impregnation, and high-temperature heat treatment, our bipolar plate has the characteristics of wear resistance, temperature resistance, pressure resistance, corrosion resistance, creep resistance, oil-free self-lubrication, small expansion coefficient, and superior sealing performance.

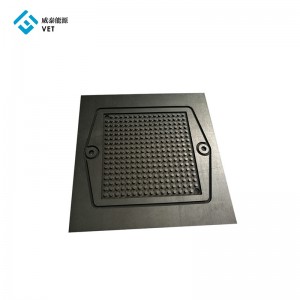

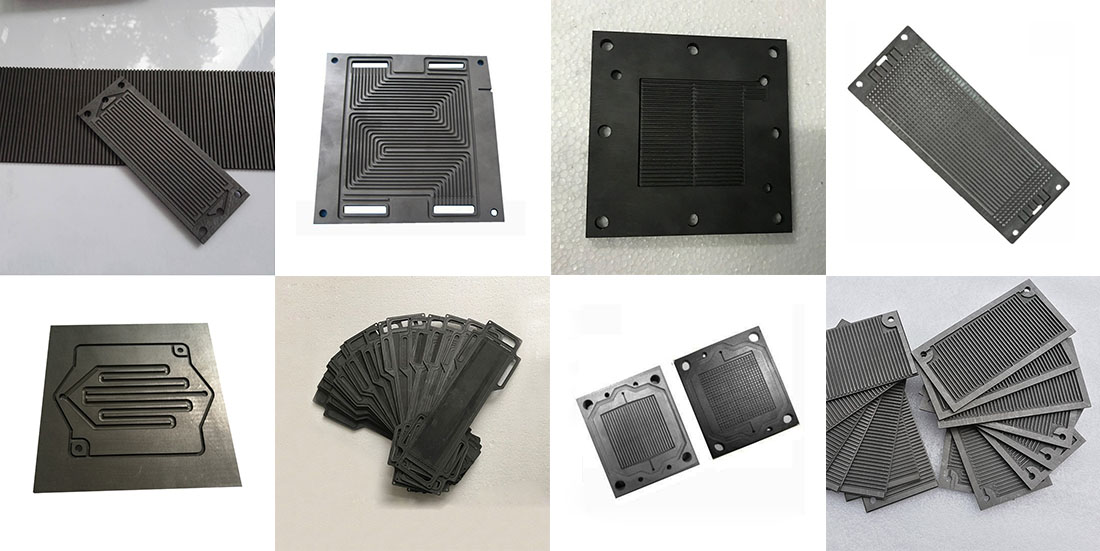

We can machine the bipolar plates on both sides with flow fields, or machine single side or provide unmachined blank plates as well. All graphite plates could be machined as per your detailed design.

Technical parameters

| Index |

Value |

| Material purity | ≥99.9% |

| Density | 1.8-2.0 g/cm³ |

| Flexural strength | >50MPa |

| Contact resistance | ≤6 mΩ·cm² |

| Operating temperature | -40℃~180℃ |

| Corrosion resistance | Immersed in 0.5M H₂SO₄ for 1000h, weight loss <0.1% |

| Minimum thickness | 0.8mm |

| Air tightness test | Pressurizing the cooling chamber by 1KG (0.1MPa), there is no leakage in the hydrogen chamber, oxygen chamber and outer chamber |

| Anti-knock performance test | The four edges of the plate are locked with a torque wrench under the condition of 13N.M, and the cooling chamber is pressurized with air pressure≥ 4.5kg (0.45MPa), the plate will not be stretched open for air leakage |

Core advantages of our bipolar plate:

1. Ultra-high conductivity, helping efficient energy conversion

High-purity graphite ≥99.9%, conductivity up to 150 S/cm, ensuring zero loss in current transmission.

Low contact resistance: The surface is polished at the nano level, and the contact resistance with the gas diffusion layer is ≤10mΩ·cm², which improves the output power of the fuel cell.

2. Extremely strong corrosion resistance, adaptable to harsh environments

Excellent chemical stability: It can withstand strong acids (such as phosphoric acid), strong alkalis and high temperature and high humidity environments, without metal ion precipitation.

Anti-oxidation coating technology (optional): Silicon carbide (SiC) protective layer is added through CVD process, and the life span is increased by more than 3 times.

3. Lightweight design, reducing system energy consumption

Density as low as 1.8 g/cm3: 20% lighter than metal bipolar plates, suitable for weight-sensitive scenarios such as vehicle-mounted fuel cells.

Thin structure: The thickness can be customized to 0.8.0-2.0mm, optimizing stacking space and improving energy density.

4. Long life and low maintenance cost

Flexural strength ≥ 40 MPa: Excellent mechanical impact resistance, avoiding brittle fracture.

Creep resistance: Continuous operation for 10,000 hours at 80℃and 95% humidity, performance degradation <5%.

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the development and production of high-end advanced materials, the materials and technology including graphite, silicon carbide, ceramics, surface treatment like SiC coating, TaC coating, glassy carbon coating, pyrolytic carbon coating, etc., these products are widely used in photovoltaic, semiconductor, new energy, metallurgy,etc.

Our technical team comes from top domestic research institutions, and have developed multiple patented technologies to ensure product performance and quality, can also provide customers with professional material solutions.