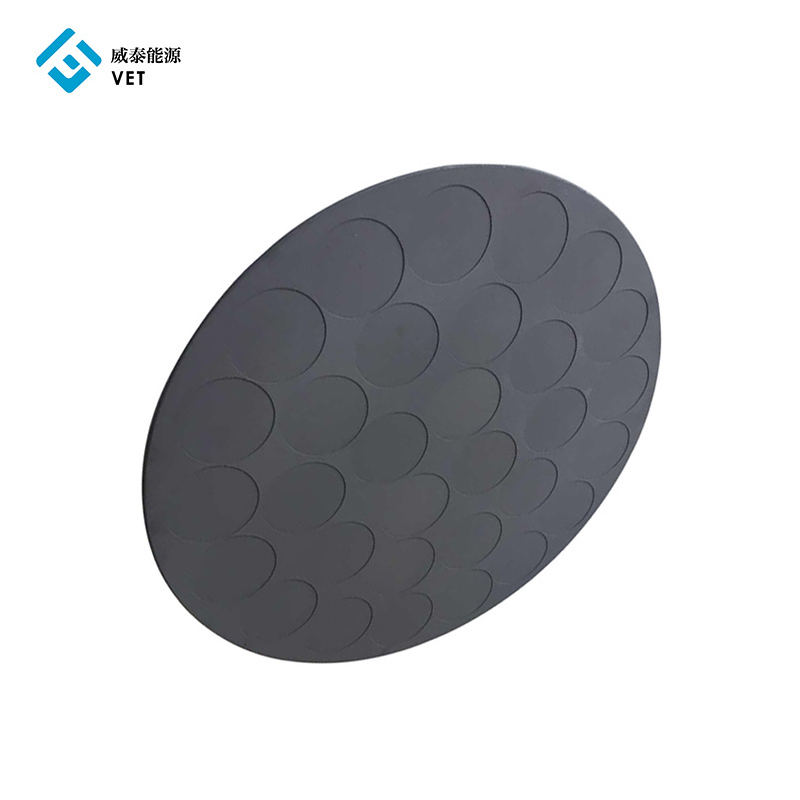

cost effective, high purity and impervious layer Silicon Carbide Coating,

active homogeneous electrochemical quality, adhesive tape, advanced materials, advanced sensor, advantage, Aerospace, alloy, aluminum, Aluminum Treatment, anode and cathode, Application, artificial graphite, Automotive, Automotive exhaust linings, Backing strips for soldering & welding, Bearings / Brushings, better heat dissipation, braking systems, bromide, bulletproof vests, Bushing, car brakes, car clutches, Carbon, Carbon fiber, carborundum, catalytic layer, Cathode, cathodes, cell stack, ceramic plates, charge, chemical energy, chemical intermediates, Chemical Pumps, chemical vapor deposition (CVD), China, coating, Cold-Isostatic-Press (CIP), Commercial & Industrial, communication, communication and multimedia systems, communication base stations, Compound Semiconductor and LED, Compressible Graphite Sheet, computer servers, Conductive Graphite Sheet, constant quality, Consumer Electronics, continuous casting, copper, CPUs, critical application, current, custom-design, Customized, CVD, decrease cost, Density, detectors, die-cut, diodes, Disc, discharge, discharge power, durability, Easy to machine, EDM, efficiency, Electric Smelting Furnace, electric vehicles, electrical conductivity, electrical conductor, Electrical Discharge Machining, electrical energy, electrical grid, electrical insulation, electricity, electro-chemical processes, electrode, electrode material, electrodeposition, electrolyte, Electron Beam Melting Crucibles, Electronic applications, electronic suspension, electrosynthesis, energy, energy density, energy efficiency, energy output, energy storage, engine management, Engineered material, epitaxial wafer, epitaxial wafer base, epitaxial growth, EV, EV Charging Station, excellent compression, excellent flexibility, Excellent thermal shock resistance, Extreme-Pressure, Extremely high thermal and chemical resistance, fabricate furnace, fabrication, fiber, Fire-Rated, flexible graphite, flow battery, flue gas treatment, Fluid-Handling Pumps, foil, Food-Handling Pumps, Fuel Cell Technologies, Fuel Pumps, FuelCell Energy, furnace, Furnace insulation, gaming stations, Glass and Refractory Industries, Glass blowing pads & plumber pads, gold, GPUS, graphene foil, Graphite Bearing, Graphite Block, Graphite Boat, Graphite Bolts&Nuts, Graphite Crucible, Graphite Electrode, Graphite Felt, Graphite Film, Graphite Gasket Material, Graphite Mold, Graphite Plate, Graphite Ring, Graphite Rod&Tube, Graphite Rotor&Vane, Graphite Semiconductor, Graphite Sheet, Green Grid, grid energy storage, HCI and H2SO4 production and recovery, heat component, heat dissipation solutions, Heat Resistance, Heat shields & sinks, heat sink, Heat Sinks, Heat Spreader, Heating Elements, HEV, High Density, High electrical conductivity, high energy efficiencies, High Frequency Power Devices, High Hardness, high intensity, high power, high power batteries, High Power Devices, high power microwave devices, high power MMIC, High purity, high radiation, high stability, High Strength, High Temperature Devices, high temperatures, High thermal conductivity, high voltage, High-Pressure, high-quality, high-quality brushes, high-strength material, High-Temperature, high-temperature capability, higher power density, highly conductive graphene material, highly conductive graphene sheet, hostile environment, hybrid vehicles, Hydrogen fuel cell stack, impervious graphite, impregnated, Impregnated graphite, increase power production, increased bandwidth capability, Increasing strength with rising temperature, industrial, Ingot Mold, insulation, Ion Implantation Components, Isostatic Graphite, isostatically molded graphite, IT Power supplies, kg, lab crucible, laboratory crucible, Laminated graphite paper, laminated with polyester, Laptops, Large-scale, less cooling, light weight, light-emitting diodes, long cycle life, low environmental impact, low-cost, lower parasitic resistances, low internal resistance, material, MEA, Medical Pumps, melting, membrane, membrane electrode assembly, memory modules, metal etching, Military, mobile devices, Mobile Electronics, MOCVD, negative, nuclear and metallurgical industries, Oil & Gas Pumps, Operating Temperature, Optoelectronic Devices, oxidation-reduction, oxidized, PAN, Paper, PEM, PEM Fuel Cell MEAs, pharmaceuticals, phosphate fertilizer, Photovoltaic, Plasma etching disk, Polyacrylonitrile, polymer, polymer membrane, polymer plate, positive, power, Power Device, power plant, power systems, power transistors, press-formed, pressure-sensitive, printed circuit boards, processing of chlorinated organics, proton exchange membrane, Pyrolytic Graphite, Pyrolytic Graphite CVD Coatings, Pyrolytic Graphite Sheet, radiation resistant applications, Rayon, Reaction surface, rechargeable flow battery, Redox flow batteries, Redox Flow Battery, reduce the cost, Refrigeration Pumps, Reinforced Compressible Graphite Sheet, reliability, Reliable performance, research and development, research labs, resiliency, Resin, ron/chromium, seal, sealing, semi-autonomous vehicles, Semi-Insulating, Semiconductor, semiconductor device, semiconductor material, Semiconductors, sensitive application, sensitive electronic parts, separator, short wavelength opto-electronic, Sic, Silicon Carbide, silicon carbide wafers, Silicon coating, Silicon Wafer, silicon wafer base, silver, size, skin temperature, smaller size, solar, solar panel, solar power systems, span energy, Sputtering Target, Sputtering Targets, stability, steel pickling, substrate, Sulfuric acid solution, Tablets, tank, target, Target Material, technical parameters, Telecommunications, temperature, temperature stability, Tensile Strength, Tensile stress, thermal conductive performance, thermal conductivity, Thermal Diffusivity, thermal grease, Thermal insulators, thermal isotropic foil, thermal management, Thickness, transportation, ultralight stoves, Utilities, Vacuum Furnace, Vacuum Pumps, vanadium, vanadium flow battery, Vanadium Redox Battery, Vanadium Redox Flow Battery, vehicle lighting and controls, VFB, vice versa, Voltage, VRB, VRF battery stacks, VRFB, water purification, Weight, work effectively, X-Y Direction, Young’s Elastic Modulus, zinc, ℃,

SiC coating of Graphite substrate for Semiconductor applications produces a part with superior purity and resistance to oxidizing atmosphere.

CVD SiC or CVI SiC is applied to Graphite of simple or complex design parts. Coating can be applied in varying thicknesses and to very large parts.

Features:

· Excellent Thermal Shock Resistance

· Excellent Physical Shock Resistance

· Excellent Chemical Resistance

· Super High Purity

· Availability in Complex Shape

· Usable under Oxidizing Atmosphere

Typical Properties of Base Graphite Material:

| Apparent Density: | 1.85 g/cm3 |

| Electrical Resistivity: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Shore Hardness: | 58 |

| Ash: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

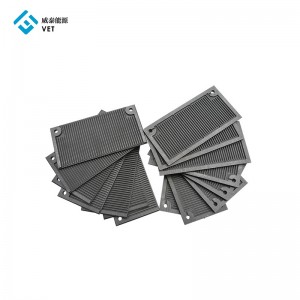

Online Exporter Bipolar Plate Graphite Anode Pl...

-

Bipolar plate hydrogen fuel cell generator 40 k...

-

Excellent thermal conductivity High Purity Grap...

-

Wholesale Discount China Carbon Vane, Graphite ...

-

OEM/ODM Supplier Graphite Block Part Vane Brick...

-

Cheap price 40um Thermal Conductivity Flexible ...