We generally believe that one’s character decides products’ excellent, the details decides products’ good quality ,with all the REALISTIC,EFFICIENT AND INNOVATIVE group spirit for Competitive Price for China 1500c Single-Zone Low-Vacuum CVD Furnace with 3-Channel Mass Flowmeter, To improved expand sector, we sincerely invite ambitious individuals and corporations to join as an agent.

We generally believe that one’s character decides products’ excellent, the details decides products’ good quality ,with all the REALISTIC,EFFICIENT AND INNOVATIVE group spirit for Chemical Vapor Deposition Furnace, China 1500c Single-Zone Low-Vacuum CVD Furnace, “Good quality and reasonable price” are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

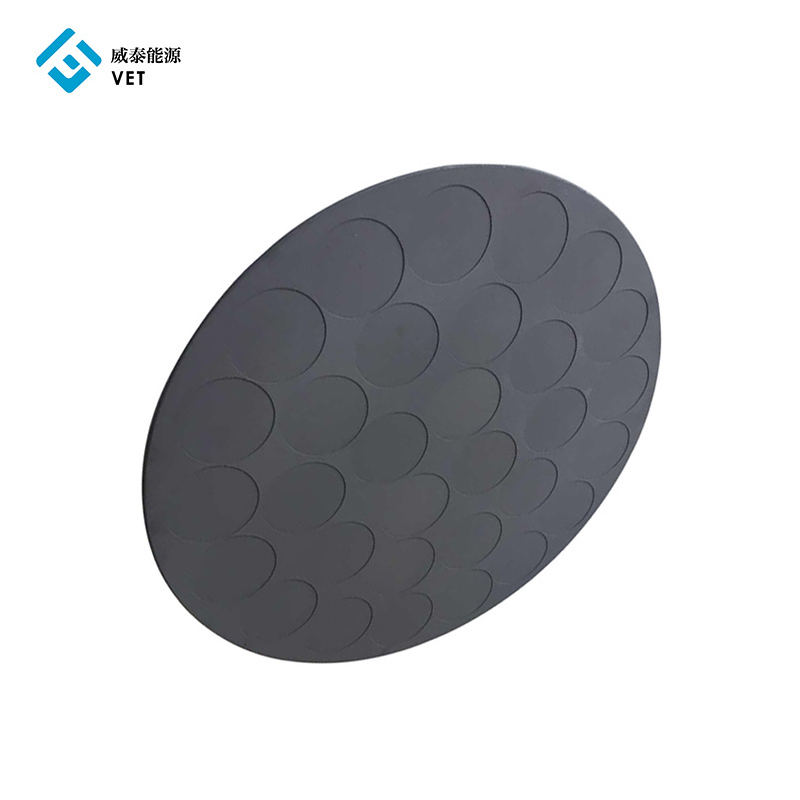

SiC coating of Graphite substrate for Semiconductor applications produces a part with superior purity and resistance to oxidizing atmosphere.

CVD SiC or CVI SiC is applied to Graphite of simple or complex design parts. Coating can be applied in varying thicknesses and to very large parts.

Features:

· Excellent Thermal Shock Resistance

· Excellent Physical Shock Resistance

· Excellent Chemical Resistance

· Super High Purity

· Availability in Complex Shape

· Usable under Oxidizing Atmosphere

Typical Properties of Base Graphite Material:

| Apparent Density: | 1.85 g/cm3 |

| Electrical Resistivity: | 11 μΩm |

| Flexural Strenth: | 49 MPa (500kgf/cm2) |

| Shore Hardness: | 58 |

| Ash: | <5ppm |

| Thermal Conductivity: | 116 W/mK (100 kcal/mhr-℃) |

Q1:What are your prices?

Our prices are subject to change on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q2:Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity.

Q3:Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q4:What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 15-25 days after receiving the deposit payment. The lead times become effective when we have received your deposit, and we have your final approval for your products. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Q5:What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance before shipment or against the copy of B/L.

Q6:What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Q7:Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

Q8:How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

-

Factory Directly supply Deep Cycle Solar Batter...

-

High Quality Hydrogen Fuel Cell Pem Membrane fo...

-

PriceList for China Refrigerator Freezer Metal ...

-

Factory making Roller for Heat Insulation Rigid...

-

OEM/ODM China China Graphite Bipolar Plate for ...

-

OEM Supply China Pbn / Pyrolytic Boron Nitride ...