Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers’ needs for China Gold Supplier for Good Quality Customizable Thickness Size Porosity Ti Fiber Felt for Fuel Cell, We now have deep cooperation with hundreds of factories all over China. The solutions we supply can match together with your different requires. Choose us, and we won’t make you regret!

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers’ needs for China Titanium Fiber Felt and Titanium Electrode, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, you should contact us. And It is our great pleasure if you like to have a personally meeting in our office.

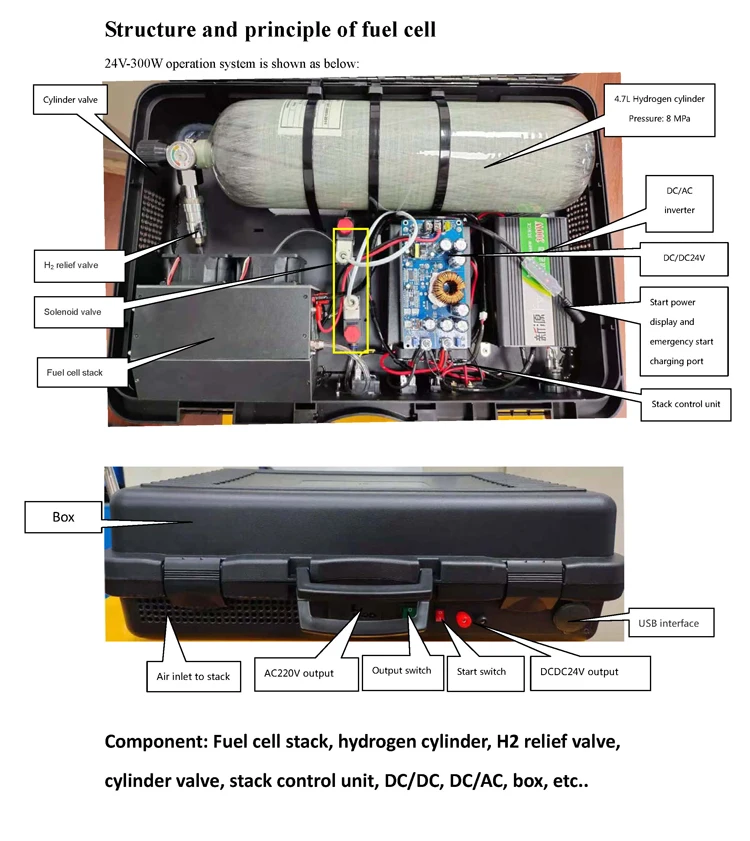

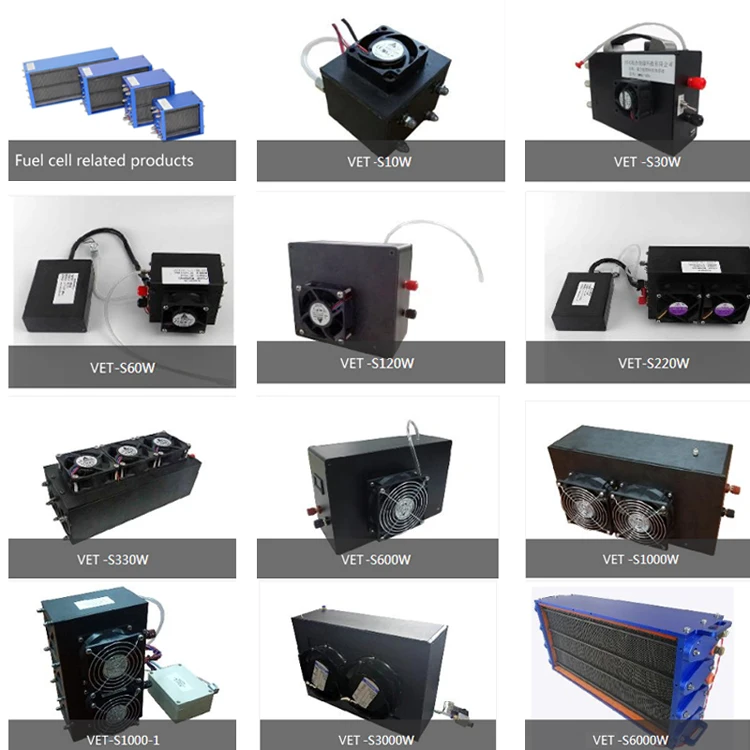

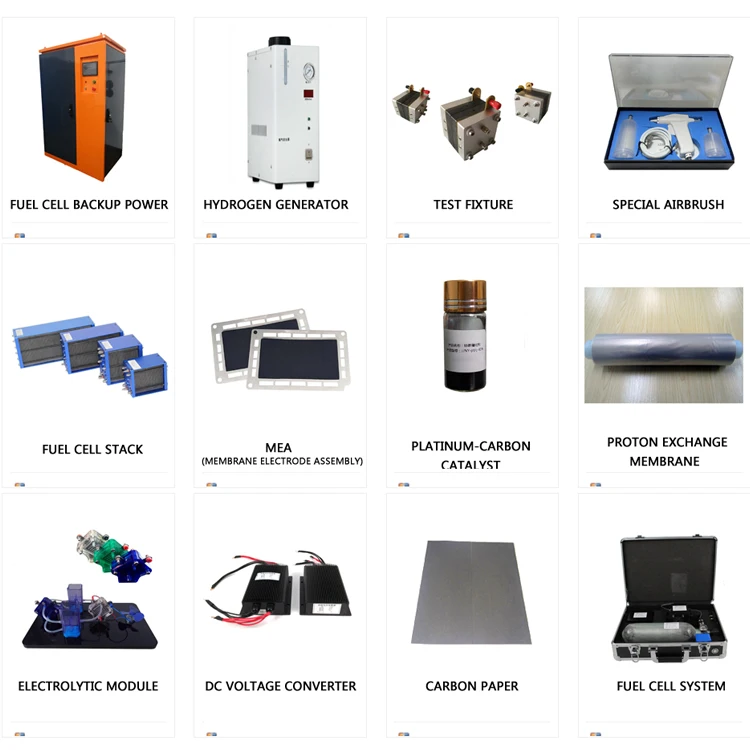

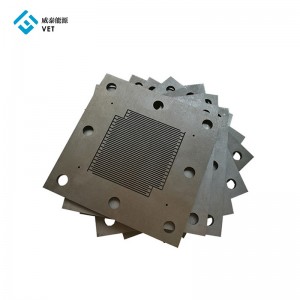

Metal Fuel Cell Electrical Bicycles/Motors Hydrogen Fuel Cell

A single fuel cell consists of a membrane electrode assembly (MEA) and two flow-field plates delivering about 0.5 and 1V voltage (too low for most applications). Just like batteries, individual cells are stacked to achieve a higher voltage and power. Thisassembly of cells is called a fuel cell stack, or just a stack.

The power output of a given fuel cell stack will depend on its size. Increasing the number of cells in a stack increases the voltage, while increasing the surface area of the cells increases the current. A stack is finished with end plates and connections for ease of further use.

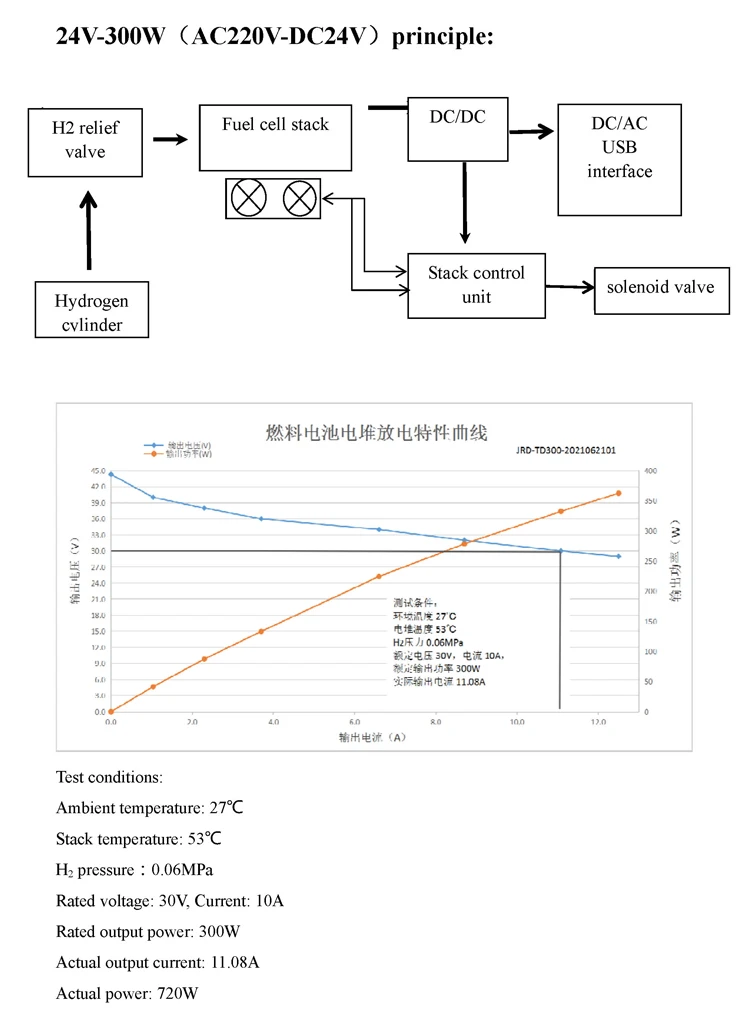

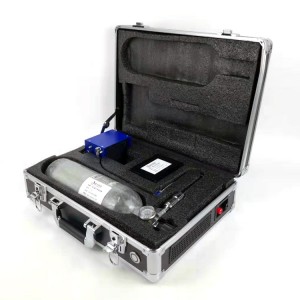

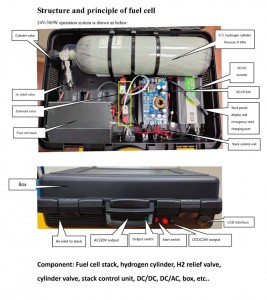

JRD-24V-300W

(AC220V/DC24V)

Performance parameters of fuel cell system

|

Overall |

Rated power | 300W |

| Rated voltage | AC220V/DC24V | |

| Rated working hours | 4-6h | |

| Ambient temperature | -50C—400C | |

| Ambient humidity | 10%RH—95%RH | |

| Weight(kg) | 4.0kg | |

| Volume (mm) | 620x400x180 | |

|

Hydrogen cylinder |

Capacity | 4.7L |

| Recommended max pressure | 15MPa(Pre-filling 8MPa) | |

|

Stack |

Rated power | 330W |

| Rated current | 11A | |

| Voltage range | 28-40V | |

| Efficiency | ≥50% | |

| Oxidant/coolant | Air (at standard atmospheric pressure) | |

|

Fuel |

Hydrogen purity | ≥99.99% |

| Working pressure | 0.045Mpa-0.055Mpa | |

| Hydrogen consumption | 0.2-6.5 L/min |

Temperature range of fuel cell during normal operation:

| Application range temperature | Recommended temperature | |

| Ambient temperature | -50C—400C | 150C—300C |

| Ambient humidity | 10%—95% | 30%—90% |

JRD-42V-1000W

(AC220V/DC42V)

|

Output performance |

rated power |

1000W |

|||

|

Rated voltage |

42V |

||||

|

Rated current |

23.8A |

||||

|

DC voltage range |

35-60V |

||||

|

effectiveness |

≥50% |

||||

|

Fuel |

Hydrogen purity |

≥99.99% ( CO< 1PPM) |

|||

|

Hydrogen pressure |

0.045~ 0.06Mpa |

||||

|

Environmental characteristics |

Working temperature |

-5~ 35 ℃ |

|||

|

Working environment humidity |

10%~ 95% (No mist) |

||||

|

Storage temperature |

-10~ 50 ℃ |

||||

|

noise |

≤60dB |

||||

|

Physical parameter |

Stack size (mm) |

291 * 160 * 98 |

|||

|

System size (mm ) |

380 * 200 * 106 |

380 * 200 * 144 (including fan) |

|||