Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for Cheap PriceList for China High Purity Carbon Graphite Bushing Bearing, Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for China Graphite Crucible, Minerals & Materials, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Sintered Silicon Carbide Ceramic Bushing

Pressureless sintered silicon carbide (SSIC) is produced using very fine SiC powder containing sintering additives. It is processed using forming methods typical for other ceramics and sintered at 2,000 to 2,200° C in an inert gas atmosphere.As well as fine-grained versions, with grain sizes < 5 um, coarse-grained versions with grain sizes of up to 1.5 mm are available.

SSIC is distinguished by high strength that stays nearly constant up to very high temperatures (approximately 1,600° C), maintaining that strength over long periods!

Product advantages:

High temperature oxidation resistance

Excellent Corrosion resistance

Good Abrasion resistance

High coefficient of heat conductivity

Self-lubricity, low density

High hardness

Customized design.

Technical properties:

| Items | Unit | Data |

| Hardness | HS | ≥110 |

| Porosity Rate | % | <0.3 |

| Density | g/cm3 | 3.10-3.15 |

| Compressive | MPa | >2200 |

| Fractural Strength | MPa | >350 |

| Coefficient of expansion | 10/°C | 4.0 |

| Content of Sic | % | ≥99 |

| Thermal conductivity | W/m.k | >120 |

| Elastic Modulus | GPa | ≥400 |

| Temperature | °C | 1380 |

-

Best bulk price carbon graphite block used for ...

-

Antimony impregnated seal graphite carbon ring

-

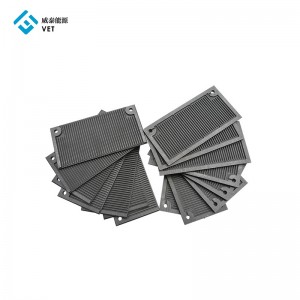

Fuel Cell Grade Graphite Plate, Carbon bipolar ...

-

Carbon Graphite Block, isostatic pressing graph...

-

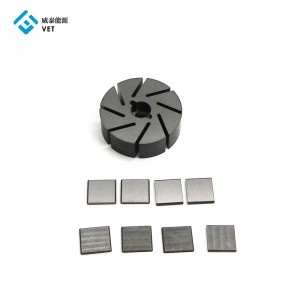

Carbon graphite rotor for sale

-

Carbon graphite vane for busch vacuum pumps

-

Carbon pump vanes for vacuum forming & vac...

-

Carbon rings in mechanical seals, graphite ring...

-

Carbon seal ring , Graphite Piston Rings for Ro...

-

China Factory for China Sintered Silicon Carbid...

-

Clay graphite crucible otational Molding type

-

Composite electrode plate for vanadium redox fl...

-

Custom cheap reusable High Pure Graphite Graphi...

-

Custom graphite heating elements,carbon parts f...

-

Customized Graphite Heater for Semiconductor Si...

-

Customized Metal Melting SIC Ingot Mould,Silico...