|

Grade of Graphite Material |

||||||||

| Material Name | Type No | Bulk Density | SpecificResistance | FlexuralStrength | Compressive Strength | Ash Max | Particle size | Processing |

| g/cm3 | μΩm | Mpa | Mpa | % | Max | |||

| Electrode Graphite | VT-RP | ≥1.55~1.75 | 7.5~8.5 | ≥8.5 | ≥20 | ≤0.3 | ≤8~10mm | Impregnation Optional |

|

Vibration Graphite |

VTZ2-3 | ≥1.72 | 7~9 | ≥13.5 | ≥35 | ≤0.3 | ≤0.8 mm | Two ImpregnationThree Baking |

| VTZ1-2 | ≥1.62 | 7~9 | ≥9 | ≥22 | ≤0.3 | ≤2 mm | One ImpregnationTwo Baking | |

| Extruded Graphite | VTJ1-2 | ≥1.68 | 7.5~8.5 | ≥19 | ≥38 | ≤0.3 | ≤0.2 mm | One ImpregnationTwo Baking |

| Molded Graphite | VTM2-3 | ≥1.80 | 10~13 | ≥40 | ≥60 | ≤0.1 | ≤0.043 mm | Two ImpregnationThree Baking |

| VTM3-4 | ≥1.85 | 10~13 | ≥47 | ≥75 | ≤0.05 | ≤0.043 mm | Three ImpregnationFour Baking | |

| Isostatic Graphite | VTD2-3 | ≥1.82 | 11~13 | ≥38 | ≥85 | ≤0.1 | 2μm, 6μm, 8μm, 15μm,etc… | Two ImpregnationThree Baking |

| VTD3-4 | ≥1.88 | 11~13 | ≥60 | ≥100 | ≤0.05 | ≤0.015 mm | Three ImpregnationFour Baking | |

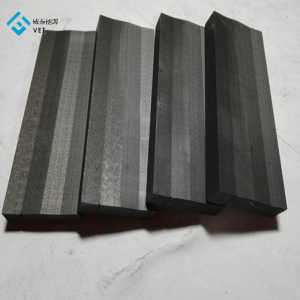

Carbon Graphite Material

Application for different graphite products

| Product Name | Industry | Application |

| Crucible,Boat,Dish,etc. | Metallurgy | Melting,refining and analysis |

| Dies,Molds,Ingot Chassis,etc. | EDM graphite electrodes,semiconductor manufacturing,iron,steel and nonferrous metal making,continuous casting,metallurgy pressing machine | |

| Graphite Roller,etc. | Heat treatment of steel plate in furnace | |

| Conduit,Skateboard,etc. | Aluminum molding | |

| Graphite Pipe | Guard pipe for measuring temperature,blowpipe,etc | |

| Graphite Block | Masonry furnace and other heat resistance material | |

| Chemical Equipment | Chemistry | Heat exchanger,reaction tower,distillation columns,absorption equipment,centrifugal pumps,etc |

| Electrolytic Plate | Salt solution and baking molten salt electrolyte | |

| Electrolytic Mercury | NaCI electrolyte | |

| Grounded Anode | Electrical anticorrosion | |

| Motor Brush | Electricity | Commutator,slipping ring |

| Current Collector | Skate,slide,trolley | |

| Contact | Switches,relays | |

| Mercury Ferry And Electronic Pipe | Electronics | Anode,grid pole,repeller pole,ignition pole of the Mercury rectifier and anode,grid electrode |

| Graphite Bearing | Machinery | High temperature resistance sliding bearing |

| Sealing Element | Sealing ring,stuffing box seal,packing seal | |

| Product Element | Braking in plane and vehicle | |

| Nuclear Graphite | Nuclear Power | Deceleration materials,reflective materials,shielding materials,nuclear fuel,support devices,etc |

Ningbo VET Energy Technology Co., Ltd is a high-tech enterprise focusing on the production and sales of

graphite products and automotive products. our main products including: graphite electrode, graphite

crucible, graphite mold, graphite plate, graphite rod, high purity graphite, isostatic graphite,etc.

We have advanced graphite processing equipment and exquisite production technology, with graphite CNC

processing center, CNC milling machine, CNC lathe, large sawing machine, surface grinder and so on. We

can process all kinds of difficult graphite products according to customers’requirements.

In line with the enterprise spirit of “integrity is the foundation, innovation is the driving force, quality is the

guarantee”, adhering to the enterprise tenet of “solving problems for customers, creating the future for

employees”, and taking “promoting the development of low-carbon and energy-saving cause” as our

mission, we strive to build a first-class brand in the field.

We usually quote within 24 hours after getting your detailed requirements,like size, quantity etc. .

If it is an urgent order, you can call us directly.

Yes, samples are available for you to check our quality.

Samples delivery time will be about 3-10 days.

The lead time is based on the quantity,about 7-12days.For graphite product,apply

We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you.

Besides that, we can also shipping by Air and Express.