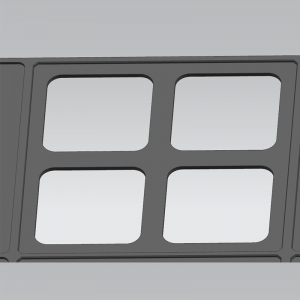

Carbon-carbon sagger/tray is made of carbon carbon composite material(CFC) processing into a high-temperature container, it has a light weight, high strength, good thermal shock resistance, high purity, wear resistance and a series of excellent performance, is an excellent high-temperature hot field materials, the applications include: lithium battery anode materials, lithium iron phosphate anode material sintering container, high-temperature powder metallurgy sintering boat and so on.

VET Energy is specialized in high-performance carbon-carbon composite (CFC) customized components, we provide comprehensive solutions from material formulation to finished products manufacturing. With complete capabilities in carbon fiber preform preparation, chemical vapor deposition, and precision machining, our products are widely used in semiconductor, photovoltaic, and high-temperature industrial furnace applications.

|

Technical Data of Carbon-Carbon Composite |

||

| Index |

Unit |

Value |

| Bulk density |

g/cm3 |

1.40~1.50 |

| Carbon content |

% |

≥98.5~99.9 |

| Ash |

PPM |

≤65 |

| Thermal conductivity (1150℃) |

W/m.k |

10~30 |

| Tensile strength |

Mpa |

90~130 |

| Flexural Strength |

Mpa |

100~150 |

| Compressive strength |

Mpa |

130~170 |

| Shear strength |

Mpa |

50~60 |

| Interlaminar Shear strength |

Mpa |

≥13 |

| Electric resistivity |

Ω.mm2/m |

30~43 |

| Coefficient of Thermal Expansion |

106/K |

0.3~1.2 |

| Processing Temperature |

℃ |

≥2400℃ |

| Military quality, full chemical vapor deposition furnace deposition, imported Toray carbon fiber T700 pre-woven 3D needle knitting. Material specifications: maximum outer diameter 2000mm, wall thickness 8-25mm, height 1600mm | ||