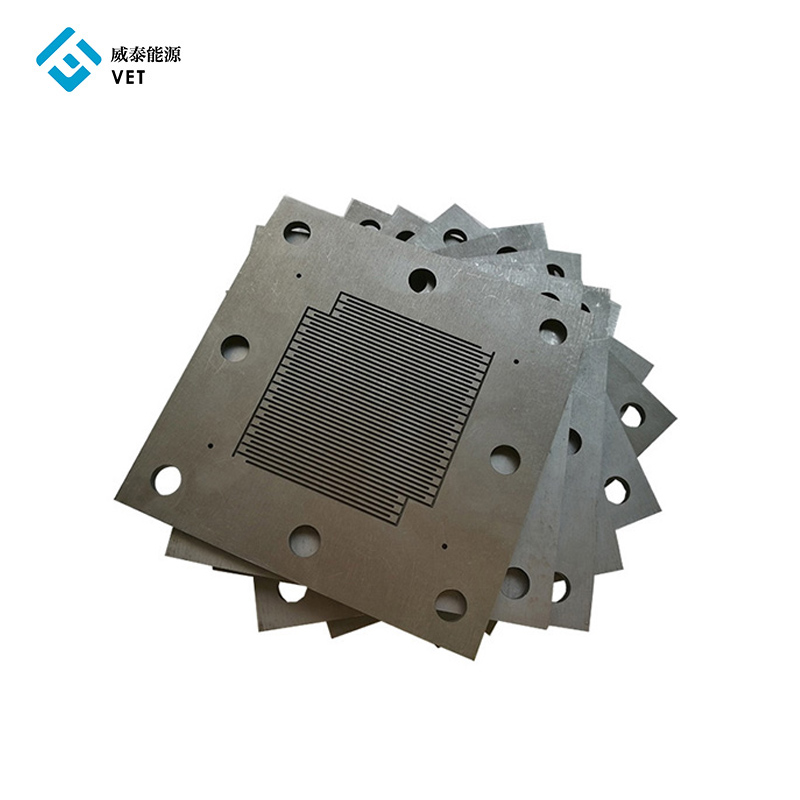

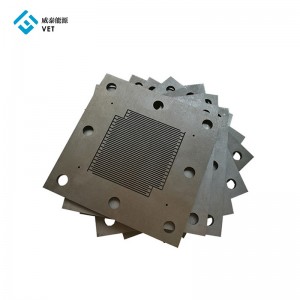

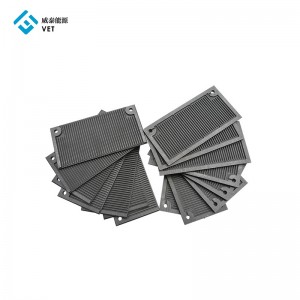

Bipolar Graphite Plate, graphite bipolar plate for hydrogen fuel cell,

Bipolar Graphite Plate, bipolar plate, Bipolar Plate for Hydrogen Fuel Cell, Carbon bipolar plate for hydrogen fuel cell, Fuel Cell Bipolar Plate,

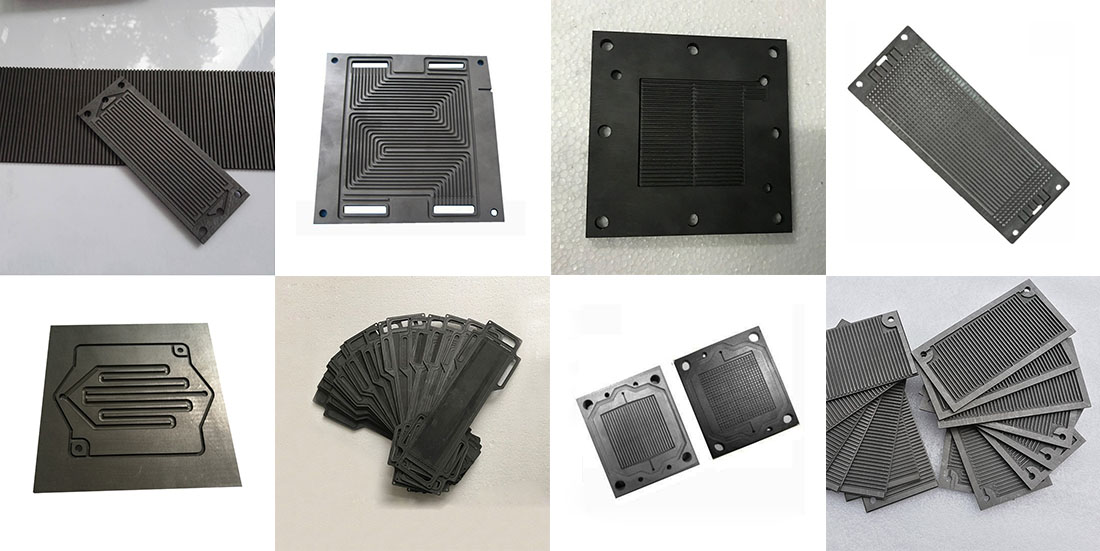

We have developed cost- effective graphite bipolar plates for PEMFC which requires the use of advanced bipolar plates with high electrical conductivity and good mechanical strength. Our bipolar plates allow fuel cells to operate at high temperatures and have excellent electrical and thermal conductivity.

We offer the graphite material with impregnated resin in order to achieve gas impermeability and high strength. But the material retains the favorable properties of graphite in terms of high electrical conductivity and high thermal conductivity.

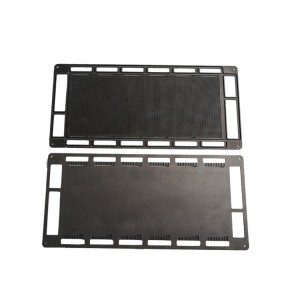

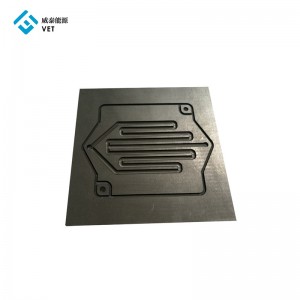

We can machine the bipolar plates on both sides with flow fields, or machine single side or provide unmachined blank plates as well. All graphite plates could be machined as per your detailed design.

Graphite Bipolar Plates Material Datasheet:

| Material | Bulk Density | Flexural Strength |

Compressive Strength | Specific Resistivity | Open Porosity |

| GRI-1 | 1.9 g/cc min | 45 Mpa min | 90 Mpa min | 10.0 micro ohm.m max | 5% max |

| More grades of graphite materials are available to select according to specific application. | |||||

Features:

- Impermeable to gases ( hydrogen and oxygen)

- Ideal electrical conductivity

- A balance between conductivity, strength, size and weight

- Resistance to corrosion

- Easy to produce in bulk Features:

- Cost-effective

-

New Arrival China Silicon Carbide Graphite Cruc...

-

Fixed Competitive Price High Quality Graphite B...

-

18 Years Factory USB Mini Vacuum Bags Pump Hand...

-

Wholesale Price 2.5kg Graphite Crucible for Mel...

-

Manufacturer for China Best Price New Product G...

-

Good Quality Ouzheng High Purity Graphite Plate...