Graphite material is a bipolar plate material that was developed and utilized earlier. Traditional bipolar plates mainly use non-porous graphite plates, and the grooves are processed by machining. The graphite bipolar plate has low thermal expansion coefficient, good thermal conductivity, stable chemical properties, good corrosion resistance and strong electrical conductivity. However, the brittleness of graphite causes processing difficulties, and at the same time restricts the reduction of the thickness of the graphite plate, and it is easy to produce pores during the manufacturing process, so that the fuel and the oxidant can penetrate each other, so other substances must be added to improve battery performance.

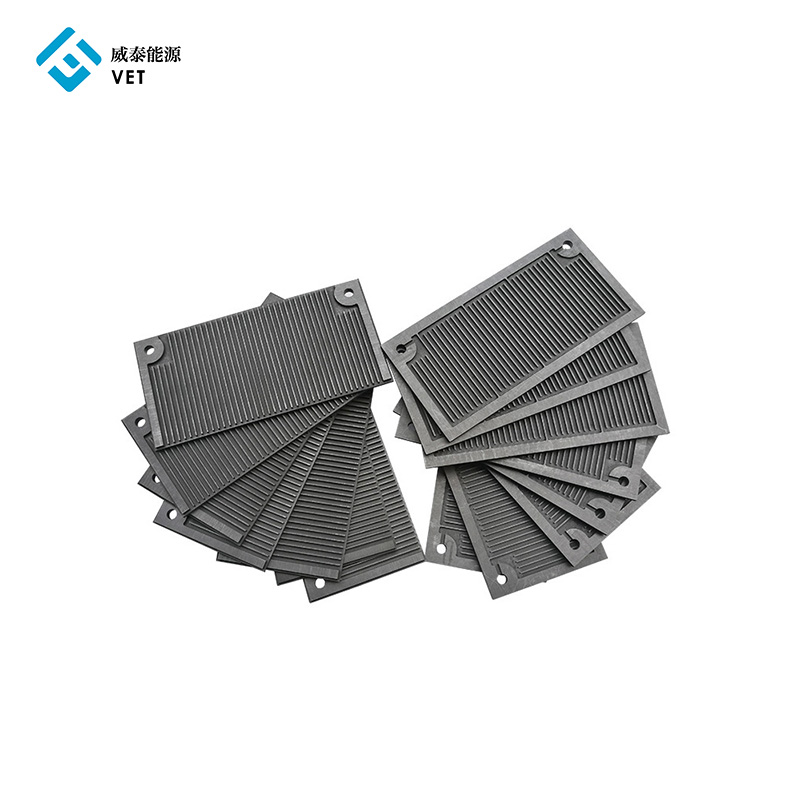

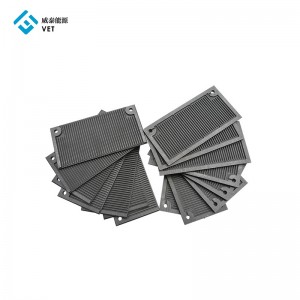

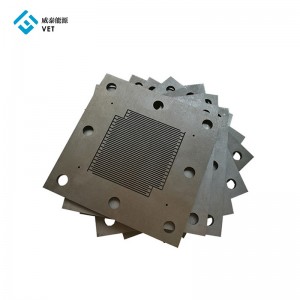

We have developed cost- effective graphite bipolar plates for PEMFC which requires the use of advanced bipolar plates with high electrical conductivity and good mechanical strength. Our bipolar plates allow fuel cells to operate at high temperatures and have excellent electrical and thermal conductivity.

We offer the graphite material with impregnated resin in order to achieve gas impermeability and high strength. But the material retains the favorable properties of graphite in terms of high electrical conductivity and high thermal conductivity.

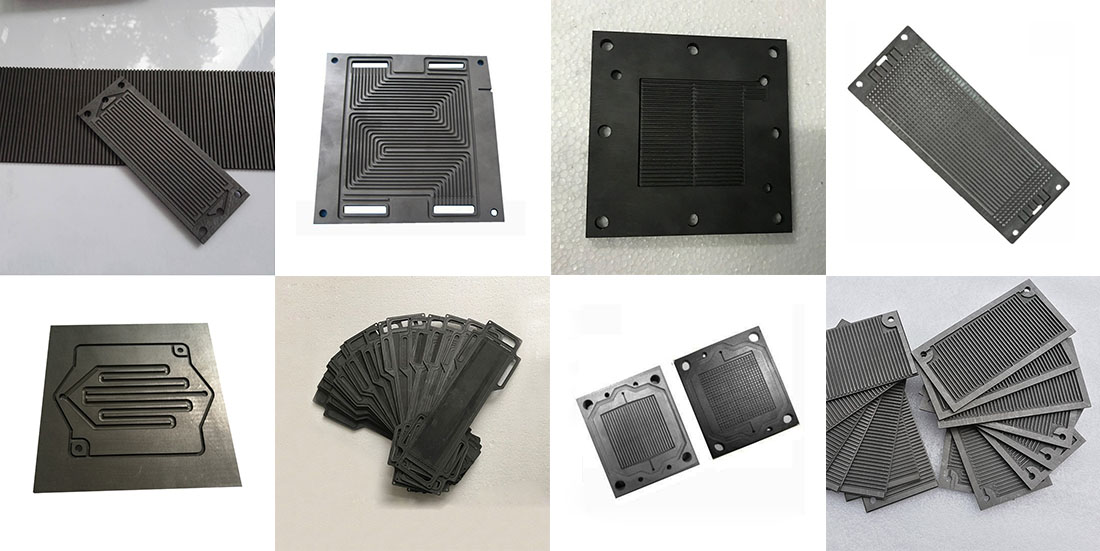

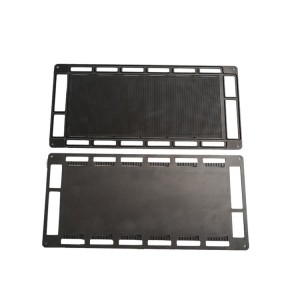

We can machine the bipolar plates on both sides with flow fields, or machine single side or provide unmachined blank plates as well. All graphite plates could be machined as per your detailed design.

Graphite Bipolar Plates Material Datasheet:

| Material | Bulk Density | Flexural Strength |

Compressive Strength | Specific Resistivity | Open Porosity |

| GRI-1 | 1.9 g/cc min | 45 Mpa min | 90 Mpa min | 10.0 micro ohm.m max | 5% max |

| More grades of graphite materials are available to select according to specific application. | |||||

Features:

- Impermeable to gases ( hydrogen and oxygen)

- Ideal electrical conductivity

- A balance between conductivity, strength, size and weight

- Resistance to corrosion

- Easy to produce in bulk Features:

- Cost-effective

-

Graphite plate fuel cell for fuel cell, Graphit...

-

Electrolysis/ electrode/ cathode graphite plate

-

The manufacturer directly provides high-quality...

-

Integrated electrode assembly, integrated MEA f...

-

New 2020 product idea Has excellent electrical ...

-

grade graphite bipolar plates for fuel cell, Bi...