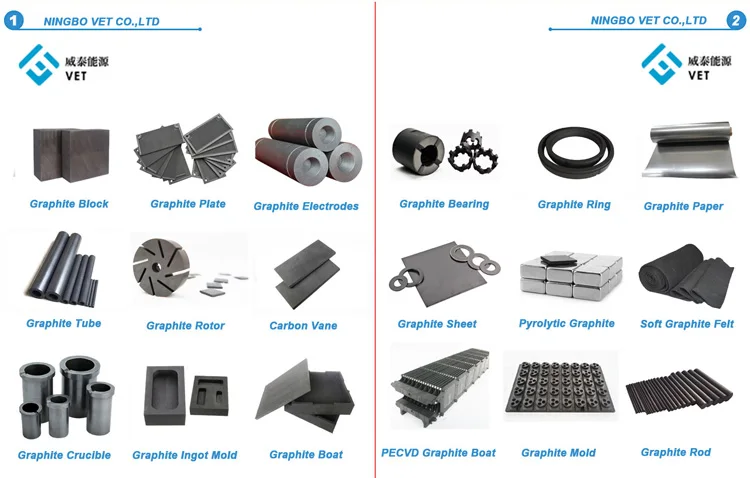

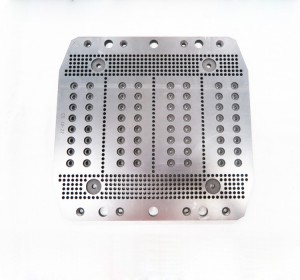

Xoog sare oo saafi ah Graphite Sintering Molds ee Aaladaha Dheeman

Astaamaha caaryada garaafka:

1. Caaryada graphite waa mid ka mid ah qalabka kulaylka u adkeysiga badan waqtigan.

2. Iyada oo iska caabbinta shoogga kulaylka ee wanaagsan, ma dhici doonto dildilaacyo marka heerkulku kulul yahay oo qabow yahay

3. Dhaqdhaqaaqa kulaylka oo aad u fiican iyo sifooyinka korantada

4. Sifeynta wanaagsan iyo caabbinta naaxinta

5. Degganaanshaha kiimikada, caabbinta aashitada iyo alkali iyo caabbinta daxalka, ma fududa in laga falceliyo biraha intooda badan

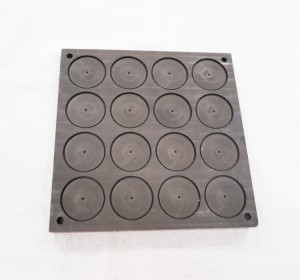

6. Warshada sahayda graphite sintering caaryada fudud si loo farsameeyo, waxqabadka farsamaynta farsamo wanaagsan, machining kara qaab adag iyo caaryada saxda ah sare

Codsiga

Caaryada graphite ayaa si weyn loogu isticmaalay dhinacyada soo socda:

1.Caaryada tuurista joogtada ah

2.Cadaadis Foundry caaryada

3.Muraayadaha dhalada oo dhinta leh

4.Sintering caaryada

5.Centrifugal tuurista caaryada

6. Dahabka, qalinka, dahabka

-

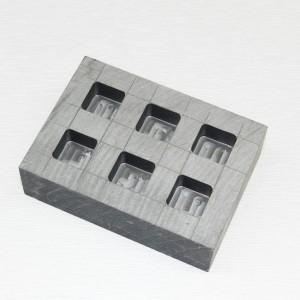

0.25oz qalin Graphite Ingot Mold

-

0.5Lb Copper Graphite Ingot Mold

-

1.75oz dahab ah Graphite Ingot Mold

-

10oz dahab ah oo shubaya Graphite Ingot Mold

-

1kg dahab ah Graphite Ingot Mold

-

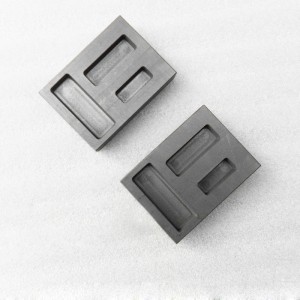

1oz Gold Bar Graphite Ingot Mold

-

3Kg Dahab Bar Graphite Ingot Mold

-

5oz dahab ah Graphite Ingot Mold

-

Dhoobada graphite crucible otational otational Molding nooca

-

Noocyada la habeeyey ee Sawir-qaadista Elektrooniga ah...

-

Qiimaha warshadda tubbada garaafka, mashiinnada qaabaysan...

-

dahabka iyo qalinka caaryada Silicon Mold, Si ...

-

Kaarboon Nadiif Sare leh iyo Qaababka Garaafka ee Semi-Semic

-

Qaybaha caaryada ee Nadiifinta Sare ee Semiconduct

-

Nadiifinta Sare ee Molded Graphite oo leh qiimo jaban

-

Caaryada graphite/Jigs / hagaajinta Semiconductor E...