Feem ntau cov neeg siv khoom taw qhia, thiab nws yog peb lub hom phiaj siab tshaj plaws los ua tsis yog tsuas yog lub npe nrov tshaj plaws, ntseeg siab thiab ncaj ncees, tab sis kuj yog tus khub rau peb cov neeg siv khoom rau tus nqi qis tshaj Tuam Tshoj 1200c Plasma Enhanced Chemical Vapor DepositionPecvdNqus Funace, Xav paub ntau ntxiv txog qhov peb tuaj yeem ua rau koj, tiv tauj peb txhua lub sijhawm. Peb tos ntsoov yuav tsim kom muaj kev sib raug zoo ntawm kev lag luam nrog koj mus ntev.

Feem ntau cov neeg siv khoom taw qhia, thiab nws yog peb lub hom phiaj kawg los ua tsis tau tsuas yog tej zaum lub npe nrov tshaj plaws, ntseeg siab thiab ncaj ncees, tab sis kuj yog tus khub rau peb cov neeg siv khoom.Tuam Tshoj Plasma Enhanced Chemical Vapor Deposition, Pecvd, Peb cov cuab yeej siv siab heev, kev tswj xyuas zoo, kev tshawb fawb thiab kev tsim kho muaj peev xwm ua rau peb tus nqi qis. Tus nqi peb muab yuav tsis yog qhov qis tshaj plaws, tab sis peb lav tias nws yog qhov sib tw kiag li! Txais tos tiv tauj peb tam sim ntawd rau yav tom ntej kev lag luam kev sib raug zoo thiab kev sib raug zoo!

Cov pa roj carbon / carbon composites(tom qab no hu ua "C / C lossis CFC") yog ib hom khoom sib xyaw uas yog raws li cov pa roj carbon thiab txhawb nqa los ntawm carbon fiber thiab nws cov khoom (carbon fiber preform). Nws muaj ob qho tib si inertia ntawm carbon thiab siab zog ntawm carbon fiber. Nws muaj cov khoom siv zoo, ua haujlwm kub, tiv thaiv corrosion, kev sib txhuam damping thiab thermal thiab hluav taws xob conductivity yam ntxwv

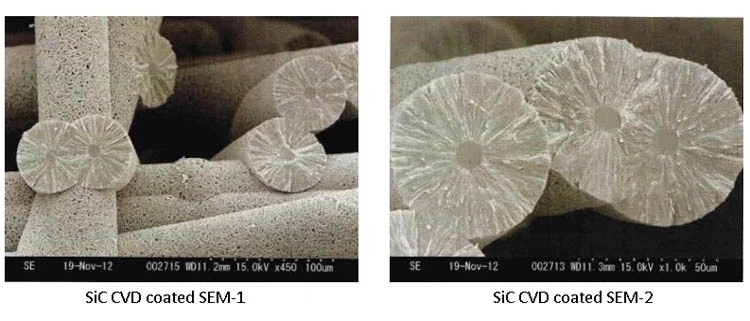

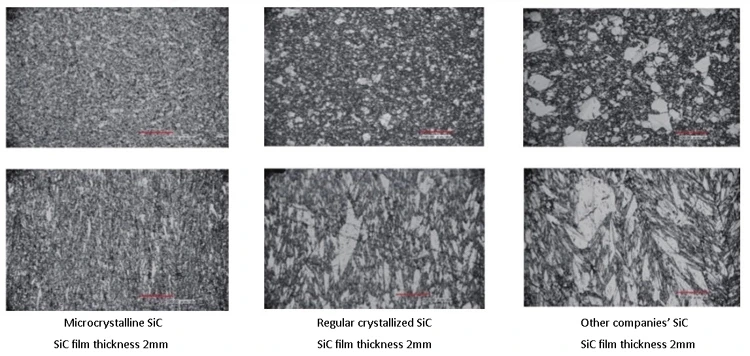

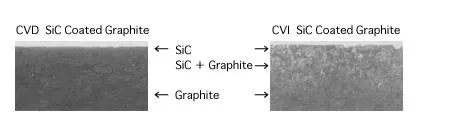

CVD-SiCtxheej txheej muaj cov yam ntxwv ntawm cov qauv zoo, cov khoom siv compact, kub tsis kam, oxidation tsis kam, siab purity, acid & alkali tsis kam thiab organic reagent, nrog lub cev ruaj khov thiab tshuaj lom neeg.

Piv nrog cov khoom siv graphite siab, graphite pib oxidize ntawm 400C, uas yuav ua rau poob ntawm cov hmoov vim oxidation, ua rau ib puag ncig muaj kuab paug rau peripheral li thiab lub tshuab nqus tsev chamber, thiab ua rau impurities ntawm high-purity ib puag ncig.

Txawm li cas los xij, SiC txheej tuaj yeem tswj lub cev thiab tshuaj lom neeg ruaj khov ntawm 1600 degrees, Nws yog dav siv hauv kev lag luam niaj hnub, tshwj xeeb tshaj yog hauv kev lag luam semiconductor.

Peb lub tuam txhab muab SiC txheej txheej txheem kev pabcuam los ntawm CVD txoj hauv kev ntawm graphite, ceramics thiab lwm yam ntaub ntawv, kom cov roj tshwj xeeb uas muaj cov pa roj carbon thiab silicon hnov mob ntawm qhov kub thiab txias kom tau txais siab purity SiC molecules, molecules tso rau saum npoo ntawm cov ntaub ntawv coated, tsim SIC tiv thaiv txheej. SIC tsim yog ruaj khov rau graphite puag, muab cov graphite puag tshwj xeeb, yog li ua rau saum npoo ntawm graphite compact, Porosity-dawb, kub tsis kam, corrosion kuj thiab oxidation kuj.

Cov yam ntxwv tseem ceeb:

1. Kub oxidation kuj:

oxidation kuj tseem zoo heev thaum kub siab li 1600 C.

2. High purity: ua los ntawm cov tshuaj vapor deposition nyob rau hauv siab kub chlorination mob.

3. Erosion kuj: siab hardness, compact nto, zoo hais.

4. Corrosion kuj: acid, alkali, ntsev thiab organic reagents.

Main Specifications ntawm CVD-SIC Txheej:

| SiC-CVD | ||

| Qhov ntom | (g / cc)

| 3.21 |

| Flexural zog | (Mpa)

| 470 ib |

| Thermal expansion | (10-6 / K) | 4

|

| Thermal conductivity | (W / mK) | 300

|