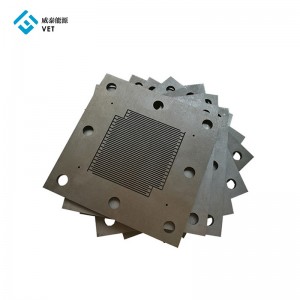

Silicon Carbide Wafer Disc yog cov khoom siv tseem ceeb siv hauv ntau cov txheej txheem tsim khoom semiconductor. peb siv peb cov cuab yeej patented los ua cov silicon carbide muaj kev nyab xeeb dua disc nrog purity siab heev, zoo txheej uniformity thiab ib tug zoo heev kev pab cuam lub neej, nrog rau cov tshuaj tiv thaiv siab thiab thermal stability.

VET Energy yog lub chaw tsim khoom tiag tiag ntawm cov khoom siv graphite thiab silicon carbide nrog cov txheej txheem sib txawv xws li SiC, TaC, pyrolytic carbon, glassy-carbon, thiab lwm yam., tuaj yeem muab ntau yam khoom siv rau kev lag luam semiconductor thiab photovoltaic. Peb pab neeg ua haujlwm los ntawm cov tsev kawm tshawb fawb sab saum toj hauv tebchaws, tuaj yeem muab cov ntaub ntawv tshaj lij tshaj lij rau koj.

Peb tsis tu ncua tsim cov txheej txheem siab heev los muab cov ntaub ntawv zoo tshaj plaws, thiab tau ua haujlwm tawm cov cuab yeej tshwj xeeb patented, uas tuaj yeem ua rau kev sib txuas ntawm cov txheej thiab cov substrate nruj dua thiab tsis tshua muaj detachment.

Fnoj ntawm peb cov khoom:

1. Kub kub oxidation tsis kam mus txog 1700℃.

2. High purity thiabthermal uniformity

3. Zoo heev corrosion kuj: acid, alkali, ntsev thiab organic reagents.

4. High hardness, compact nto, zoo hais.

5. Lub neej ua haujlwm ntev dua thiab ruaj khov dua

| CVD SiC薄膜基本物理性能 Basic Physical Properties ntawm CVD SiCtxheej | |

| 性质 / Khoom | 典型数值 / Tus nqi |

| 晶体结构 / Crystal Structure | FCC β theem多晶, 主要为(111) Ib |

| 密度 / Ceev | 3.21 g / cm³ |

| 硬度 / Hardness | 2500 维氏硬度 (500g load) |

| 晶粒大小 / Grain SiZe | 2 ~ 10 hli |

| 纯度 / Tshuaj Purity | 99.99995% |

| Cov duab / Kub Muaj Peev Xwm | 6 40j kg-1· K-1 |

| 升华温度 / Sublimation kub | 2700 ℃ |

| 抗弯强度 / Flexural zog | 415 MPa RT 4-point |

| 杨氏模量 / Young's Modulus | 430 Gpa 4pt khoov, 1300 ℃ |

| 导热系数 / KublKev coj ua | 300 Wm-1· K-1 |

| 热膨胀系数 / Thermal Expansion (CTE) | 4.5 × 10-6K-1 |

Zoo siab txais tos koj tuaj xyuas peb lub Hoobkas, cia peb tham ntxiv!

-

Tuam Tshoj Manufacturing rau Tuam Tshoj Fais Fab Supply ...

-

Tuam Tshoj Standard High Purity Dej Electroly...

-

Dawb qauv rau Graphite Flow Field Graphite Bi ...

-

Hoobkas ua Tuam Tshoj Customized Recrystalized ...

-

Lag luam wholesale luv nqi Tuam Tshoj Graphite Tube rau Rare ...

-

roj dawb uas ntsiag to cua compressor twj tso kua mis rau d ...