Nta:

- Cov nplej zoo

- Homogeneous qauv

- Siab ceev

- Zoo heev thermal conductivity

-High mechanical zog

- Tsim nyog hluav taws xob conductivity

- Tsawg wettability rau molten hlau

Qhov ntau thiab tsawg:

| Thaiv | Length x Dav x Thickness (mm) 200x200x70, 250x130x100, 300x150x100, 280x140x110, 400x120x120, 300x200x120, 780x210x120, 330x260x120, 650x200x135, 650x210x135, 380x290x140, 500x150x150, 360x150x3, 400x170x160, 550x260x160, 490x300x180, 600x400x200, 400x400x400 |

| Hloov | Loj: 60, 100, 125, 135, 150, 200, 250, 300, 330, 400, 455 Thickness (hli): 100, 135, 180, 220, 250, 300, 450 |

* Lwm qhov ntev yog muaj nyob rau ntawm kev thov.

Specifications:

| Specifications | Chav tsev | Tus nqi |

| Kev ceev ceev | g/cc | 1.70-1.85 Nws |

| Compressive zog | MPa | 30-80 |

| Khoov zog | MPa | 15–40 : kuv |

| Ntug hardness | 30–50 : kuv | |

| Tshwj xeeb Resistance | micro ohm | 8.0-15.0 Nws |

| Tshauv (Normal Qib) | % | 0.05-0.2 hli |

| Tshauv (purified) | ppm ua | 30–50 : kuv |

Daim ntawv thov:

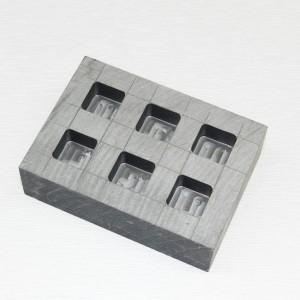

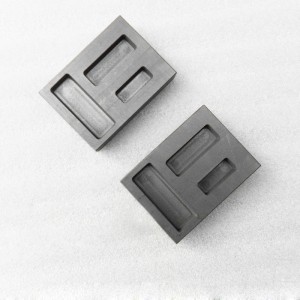

- Pwm, chutes, tes tsho, sheathes, hauv ob sab phlu, thiab lwm yam nyob rau hauv nruam casting tshuab rau ua zoo li tus hlau, cam khwb cia hlau, tooj liab, txhuas.

- Sintering pwm rau cemented carbides thiab cov cuab yeej pob zeb diamond.

- Sintering pwm rau cov khoom siv hluav taws xob.

- Electrodes rau EDM.

- Cov cua kub cua sov, cov ntaub thaiv cua sov, cov crucibles, cov nkoj hauv qee qhov kev lag luam furnaces (xws li lub cub tawg rau rub monocrystalline silicon lossis optical fibers).

- Cov kabmob thiab cov ntsaws ruaj ruaj hauv cov twj, turbines thiab motors.

- thiab lwm yam.

-

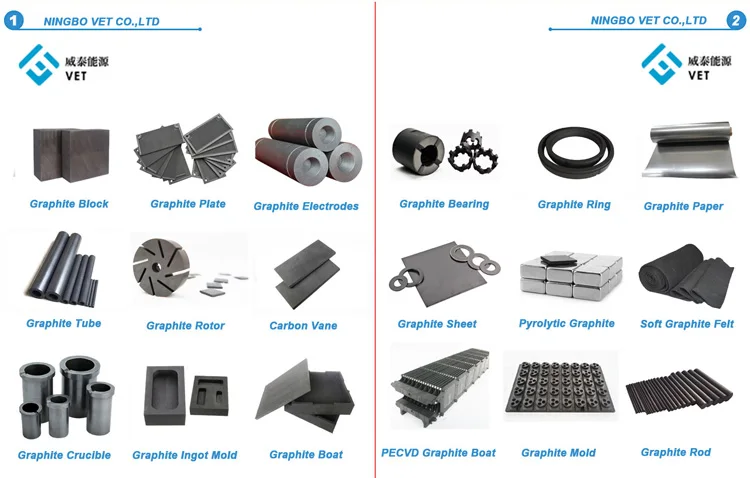

150g kub Graphite Ingot Mould

-

10oz kub casting Graphite Ingot Mould

-

0.5Lb tooj liab Graphite Ingot Mould

-

0.25oz nyiaj Graphite Ingot Pwm

-

1.75oz kub Graphite Ingot Pwm

-

1kg kub Graphite Ingot Mould

-

1oz Kub Bar Graphite Ingot Pwm

-

3Kg Kub Bar Graphite Ingot Pwm

-

Activated Carbon Fiber Npuag, activated carbon ...

-

Activated carbon fiber xav acf rau pov tseg ...

-

Antimony Alloy Graphite Bushings / Cov kabmob

-

Hauv qab nqe Tuam Tshoj Chaw tsim khoom ntawm Carbon Graphi...

-

Carbon thaiv tus nqi zoo tshaj rau arc rauv