Yuav kom muaj peev xwm ua tau raws li cov neeg siv khoom xav tau, tag nrho peb cov haujlwm tau ua nruj me ntsis raws li peb cov lus qhia "High High-quality, Competitive nqi, Fast Service" rau 18 Xyoo Lub Hoobkas Graphite Crucible rau Melting thiab Casting Hlau, Peb muaj ntau tshaj 20 xyoo kev nyob rau hauv qhov kev lag luam, thiab peb cov muag khoom tau kawm zoo. Peb tuaj yeem muab cov lus qhia tshaj lij tshaj plaws rau koj kom tau raws li koj cov khoom xav tau. Txhua yam teeb meem, tuaj rau peb!

Yuav kom muaj peev xwm ua tau raws li cov neeg siv khoom xav tau, txhua yam ntawm peb cov haujlwm tau ua nruj me ntsis raws li peb cov lus qhia "High High-quality, Competitive nqi, Fast Service" rauTuam Tshoj Graphite Pwm thiab Graphite, Ua kom txhua tus neeg siv khoom txaus siab rau peb thiab ua tiav qhov kev yeej-yeej, peb yuav txuas ntxiv sim peb qhov zoo tshaj plaws los pab thiab txaus siab rau koj! Ua siab zoo tos ntsoov rau kev koom tes nrog ntau tus neeg muas zaub txawv teb chaws raws li kev sib nrig sib pab thiab kev lag luam zoo yav tom ntej. Ua tsaug.

Siliconized graphite yog cov khoom sib xyaw uas silicon carbide txuas rau saum npoo ntawm graphite substrate. Nws muaj cov yam ntxwv ntawm siab hardness, siab mechanical zog thiab hnav tsis kam ntawm silicon carbide, nrog rau nws tus kheej-lubricating zog thiab thermal shock kuj ntawm graphite. Nws yog ib qho zoo tagnrho cov ntaub ntawv sib txhuam thiab cov khoom siv foob, haum rau kev sib khi ntawm ntau yam twj tso kua mis, roj twj, tshuaj twj, thiab bearings ntawm ntau yam high-ceev thiab high-load lub ntsiab twj. Tsis tas li ntawd, siliconized graphite muaj qhov zoo oxidation tsis kam, thermal poob siab tsis kam, porosity tsawg, thiab qee yam hluav taws xob conductivity, thiab tuaj yeem siv los ua cov ntaub ntawv xws li hlau smelting crucibles thiab cov hlab ntsha.

![]()

Cov muaj pes tsawg leeg ntawm siliconized graphite yog ib yam, qhov saum npoo yog zoo ib yam nrog rau sab hauv, thiab muaj pes tsawg leeg ntawm silicon carbide thiab graphite yog adjustable. Qhov siab dua cov ntsiab lus ntawm silicon carbide, qhov ntau dua qhov ntom ntawm cov khoom, qhov siab dua lub zog compressive, thiab cov resistivity nce.

Metallographic duab ntawm siliconized graphite

(qhov dub yog graphite, qhov grey yog silicon carbide, thiab qhov dawb yog silicon)

| 硅化石墨主要技术指标 | |

| 类别 Yam khoom | 指标 Tus nqi |

| 密度 Ceev | 2.4-2.9g / cm³ |

| Cov porosity | <0.5% |

| 抗压强度 Compressive zog | > 400MPa |

| Flexural zog Flexural zog | > 120MPa |

| Thermal conductivity | 120 W/mK |

| Thermal expansion coefficient | 4.5 × 10-6 |

| Elastic modulus | 120 GP ua |

| 冲击强度 Impact zog | 1.9 KJ/m² |

| Dej lubricated kev sib txhuam | 0.005 ib |

| Kev sib txhuam coefficient ntawm qhuav qhuav | 0.05 Nws |

| 化学稳定性 Tshuaj stability | 各种盐,有机溶剂,强酸(HF, HCl, H₂SO)4HNO ₃) Ntau cov ntsev, cov kuab tshuaj organic, muaj zog acids (HF, HCl, H₂SO4HNO ₃) |

| 长期稳定使用温度 Lub sij hawm ntev ruaj khov siv kub | 800 ℃ (氧化气氛), 2300 ℃ (惰性或真空气氛) 800 ℃ (oxidizing cua), 2300 ℃ (inert lossis nqus cua) |

| Hluav taws xob resistivity | 120 × 10-6Ωm |

Yuav kom muaj peev xwm ua tau raws li cov neeg siv khoom xav tau, tag nrho peb cov haujlwm tau ua nruj me ntsis raws li peb cov lus qhia "High High-quality, Competitive nqi, Fast Service" rau 18 Xyoo Lub Hoobkas Graphite Crucible rau Melting thiab Casting Hlau, Peb muaj ntau tshaj 20 xyoo kev nyob rau hauv qhov kev lag luam, thiab peb cov muag khoom tau kawm zoo. Peb tuaj yeem muab cov lus qhia tshaj lij tshaj plaws rau koj kom tau raws li koj cov khoom xav tau. Txhua yam teeb meem, tuaj rau peb!

18 Xyoo HoobkasTuam Tshoj Graphite Pwm thiab Graphite, Ua kom txhua tus neeg siv khoom txaus siab rau peb thiab ua tiav qhov kev yeej-yeej, peb yuav txuas ntxiv sim peb qhov zoo tshaj plaws los pab thiab txaus siab rau koj! Ua siab zoo tos ntsoov rau kev koom tes nrog ntau tus neeg muas zaub txawv teb chaws raws li kev sib nrig sib pab thiab kev lag luam zoo yav tom ntej. Ua tsaug.

-

Tus nqi zoo tshaj ntawm Rauv Sic Heater Ob Chav Kauv ...

-

Hoobkas Nqe Rau Graphite Bearing Nplhaib nrog Hi ...

-

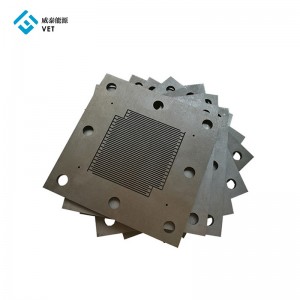

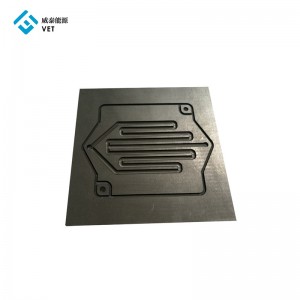

Daim ntawv teev npe rau Bipolar Graphite Electrode Phaj ...

-

Tus nqi pheej yig Tuam Tshoj Tsawg Friction Impregnated Resi ...

-

High Quality High Density Graphite Bipolar Plat...

-

Graphite Bipolar Phaj rau Hydrogen Roj Cell