Amfani:

1.CO2 Reactivity Residue iya isa sama da 91%, Air Reactivity iya isa sama da 96%; da tsawon rayuwa a cikin sel na aluminum electrolysis ne 30-33days.

2.Higher thermal shock Resistance

Fuskar zafi: <4*10

Mai Haɗa zafi: <3W/mkl

3.mafi girma halin yanzu yawa

yawa na yanzu:> 0.8A/cm2

4.lower Resistivity Electric

Juriya na Wutar Lantarki: 55-56μΩm

BAYANIN ANODE

| Jerin

| DUKIYA | Naúrar | Daidaitaccen hanya | Rage |

| 1 | Maƙarƙashiyar gaske | g/cm3 | ISO 8004 | 2 Min |

| 2 | Yawaita bayyananne | g/cm3 | ISO 12985 | 1.52-1.58 |

| 3 | Karɓar iska | npm | ISO 15906 | 0.5-1.5 |

| 5 | Ƙarfin Ƙarfi | N/mm2 | ISO 18515 | 40-48 |

| 6 | Matasa moud | Gpa | ISO 12989 | 4-5.5 |

| 7 | Ƙarfin Flexural | N/mm2 | ISO 12986 | 8-10 |

| 8 | Spe. Elec. Juriya | µΩm | ISO 11713 | 55-62 |

| 9 | Cof. Lin . Thermal | µm/(km) | ISO 14420 | 3.75-4.5 |

| 10 | Thermal Conductivity | W/ (km) | ISO 129087 | 3-4.5 |

| 11 | Ash | % | ISO 8005 | 0.5 Max |

| 12 | Sauran Reactivity na iska kura Bace

| % % %

| ISO 12989-1

| 75-85 4 – 8 10 - 20 |

| 13 | Co2 Reactivity ragowar kura rasa | % % % | ISO 12988-1

| shafi na 84-95 3 – 8 6-14 |

| 14 | Abubuwa S V Fe F Ca Al Ni SI | % ppm // // // // // | Saukewa: ASTM D6376

| 0.5-2.5 30-320 100-600 150-600 50 - 200 150-600 40 - 200 50 - 300 |

-

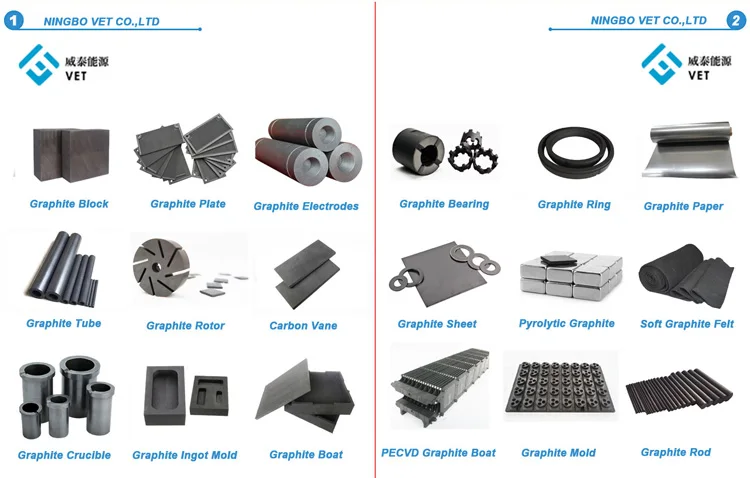

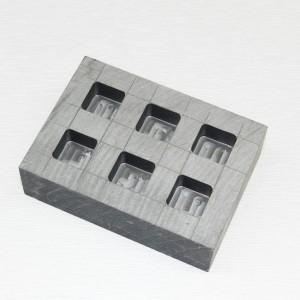

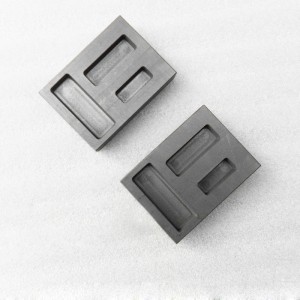

0.25oz azurfa Graphite Ingot Mold

-

0.5lb Copper Graphite Ingot Mold

-

1.75oz gwal Graphite Ingot Mold

-

10oz Zinare simintin gyare-gyaren Graphite Ingot Mold

-

150g zinariya Graphite Ingot Mold

-

1kg zinariya Graphite Ingot Mold

-

1oz Zinare Bar Graphite Ingot Mold

-

3Kg Zinare Bar Graphite Ingot Mold

-

5oz zinariya Graphite Ingot Mold

-

Kunna Carbon Fiber Fabric, Carbon da aka kunna...

-

Kunna fiber fiber ji acf don zubarwa ...

-

60W Hydrogen man fetur cell, Fuel cell tari, Proton ...

-

6KW Hydrogen Fuel Cell Stack, Hydrogen Generator ...